Hollow Concrete Blocks Market Size, Share, Trends and Forecast by Product, Application, and Region, 2025-2033

Hollow Concrete Blocks Market Size and Share:

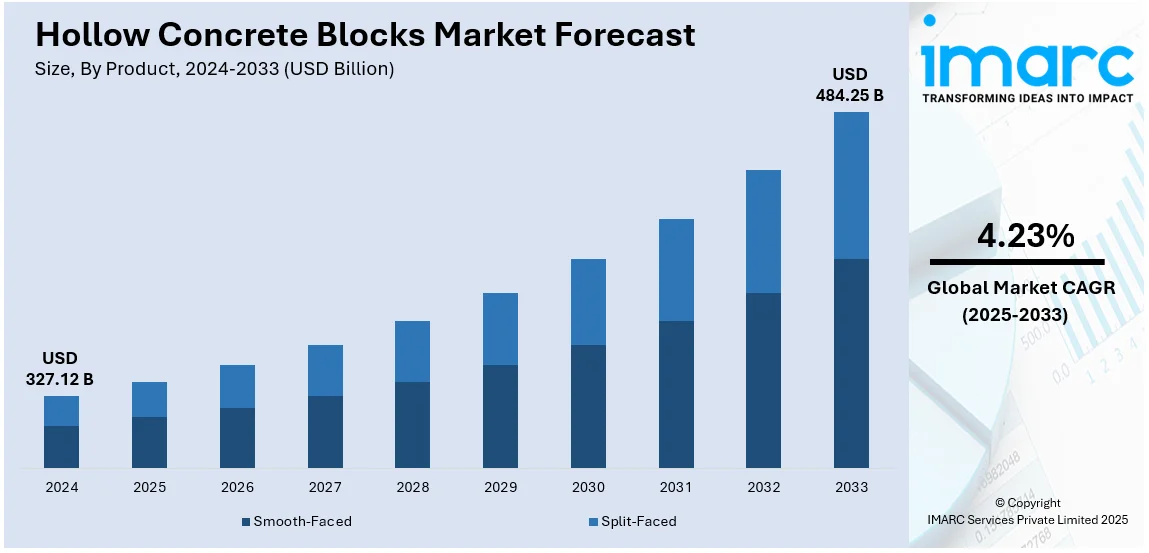

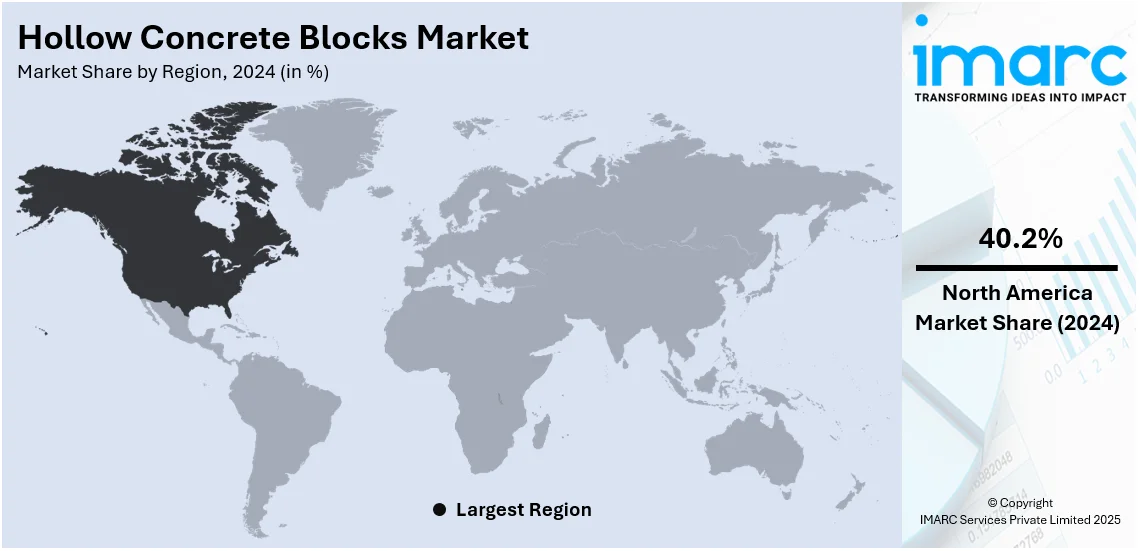

The global hollow concrete blocks market size was valued at USD 327.12 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 484.25 Billion by 2033, exhibiting a CAGR of 4.23% during 2025-2033. North America currently dominated the market, holding a significant market share of over 40.2% in 2024. The increasing construction of residential, commercial, and industrial areas, rising number of renovation and upgradation projects, and the growing adoption of sustainable construction materials represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 327.12 Billion |

|

Market Forecast in 2033

|

USD 484.25 Billion |

| Market Growth Rate (2025-2033) | 4.23% |

The hollow concrete blocks market is driven by increasing construction activities, urbanization, and infrastructure development. Cost-effectiveness, durability, and thermal insulation properties make these blocks a preferred choice over traditional bricks. Government initiatives promoting affordable housing and sustainable construction further boost demand. Rising environmental concerns drive adoption due to lower carbon emissions in manufacturing. Prefabrication trends and advancements in block-making technology enhance efficiency and quality. The expanding commercial and industrial sectors, along with growing investments in smart cities and real estate, contribute to market growth. Additionally, the demand for earthquake-resistant and fireproof materials supports the increasing use of hollow concrete blocks.

The United States stands out as a key market disruptor, supported by increasing infrastructure investments and the shift toward sustainable construction materials. The demand for energy-efficient and cost-effective building solutions is rising, particularly in commercial and residential sectors. For instance, the Infrastructure Investment and Jobs Act (IIJA) allocates $110 billion for roads, bridges, and major infrastructure projects, boosting the adoption of durable and thermally efficient hollow concrete blocks. In this context, these blocks play a vital role in enhancing structural integrity, reducing construction time, and supporting eco-friendly building practices across various large-scale developments in the U.S.

Hollow Concrete Blocks Market Trends:

Automation Driving Efficiency in Hollow Concrete Block Manufacturing

The use of modern technology in hollow concrete block production is significantly enhancing manufacturing efficiency and quality requirements. Fully automated systems, such as high-capacity block-making machines and integrated finishing lines, allow for shorter production cycles, more uniformity, and less manual work. Precision processes such as shot blasting, curling, and coating improve the durability and aesthetic appeal of concrete blocks, making them better suited to large-scale infrastructure projects. With rising demand for high-quality construction materials in quickly emerging countries, manufacturers are turning to automation to satisfy the requirements of the industry. These innovations not only expedite operations but also help to promote sustainability by reducing material waste and optimizing energy use. The use of cutting-edge technology in block production promotes the construction of modern infrastructure, particularly in areas with ambitious urban development plans. Hollow concrete block production is expected to play an increasingly important role in addressing building needs with improved efficiency and dependability. For example, in January 2025, Alomaier Trading and Contracting Company (OTC) in Saudi Arabia enhanced its operations by integrating advanced concrete block and paver machinery, including the RH 2000-4 MVA model, along with a fully automated shot blasting, curling, and coating line. This strategic move aims to boost the production quality and efficiency of hollow concrete blocks, aligning with OTC's commitment to supporting infrastructure projects across the Gulf region.

Surging Demand for Hollow Concrete Blocks in Sustainable Construction

Substantial growth in the construction sector and the increasing use of hollow concrete blocks for constructing residential, commercial, and industrial areas represent one of the key factors strengthening the growth of the market around the world. According to reports, an estimated USD 50 Billion was invested in architecture, engineering, and construction (AEC) tech between 2020 and 2022, 85 percent higher than the previous three years. These blocks are used to construct load bearing walls in buildings to provide structural support and withstand vertical loads. They are stacked and bonded together with mortar to create sturdy and stable walls. They are also utilized in the construction of fences to offer privacy and security. Moreover, the rising number of renovation and upgradation projects of restaurants, metro stations, cafes, resorts, homes, hotels, offices, shopping malls, airports, and educational institutions is favoring the growth of the market. In addition, the growing usage of hollow concrete blocks for constructing bridges, tunnels, roads, and highways, to improve the structural integrity of these buildings is influencing the market positively. Apart from this, measures undertaken by governing agencies of numerous countries to promote the adoption of sustainable construction materials like hollow concrete blocks, minimize carbon footprints, and focus on the development of smart cities on account of the increasing environmental concerns are propelling the growth of the market. For instance, the EU has a set target for 2030 of a 55% net reduction in greenhouse gas emissions. Furthermore, key players are extensively funding various research and development (R&D) activities to develop aerated hollow concrete blocks that are infused with air voids to improve insulation, reduce weight, and enhance fire resistance. They are also incorporating nanoscale additives like nanofibers that are resistant to cracks or deterioration.

Advancing Hollow Concrete Block Production

Ethiopia is witnessing a shift in hollow concrete block manufacturing with the adoption of advanced block-making machines. While the market has been dominated by Turkish manufacturers using older technologies, newer equipment is enabling more efficient and high-quality production. This shift supports the country’s growing construction sector by improving the durability and availability of hollow concrete blocks. Enhanced automation in block production is expected to reduce labor costs, increase output, and ensure consistency in block quality. As infrastructure projects expand, the demand for reliable and structurally sound building materials continues to rise. The adoption of modern manufacturing techniques aligns with Ethiopia’s efforts to enhance local construction capabilities, reduce reliance on imports, and promote sustainable building practices. With growing urbanization and government-backed infrastructure projects, the need for cost-effective and energy-efficient construction materials is accelerating. The increasing integration of automated block-making solutions is expected to strengthen Ethiopia’s position in the regional construction market. For instance, in February 2024, two QT6 cement block machines arrived in Ethiopia. Despite the presence of numerous Turkish block factories in the country, many utilize older technologies. The introduction of these advanced machines is expected to enhance the local production of hollow concrete blocks, potentially influencing the Ethiopian construction sector.

Hollow Concrete Blocks Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global hollow concrete blocks market, along with forecasts at the global, regional, and country levels from 2025-2033. The market has been categorized based on product and application.

Analysis by Product:

- Smooth-Faced

- Split-Faced

Split-faced represented the largest component in 2024, holding around 63.7% of the market. The split-faced segment is a significant driver of the hollow concrete blocks market, primarily due to its aesthetic appeal, durability, and cost-effectiveness. Split-faced hollow concrete blocks offer a textured surface that enhances architectural designs while maintaining structural integrity. These blocks are widely used in commercial, residential, and institutional buildings, where both functionality and visual appeal are critical. Their rough, exposed aggregate finish provides improved weather resistance and requires minimal maintenance, making them ideal for exterior and load-bearing walls. The growing preference for decorative yet sturdy construction materials fuels demand in urban infrastructure projects.

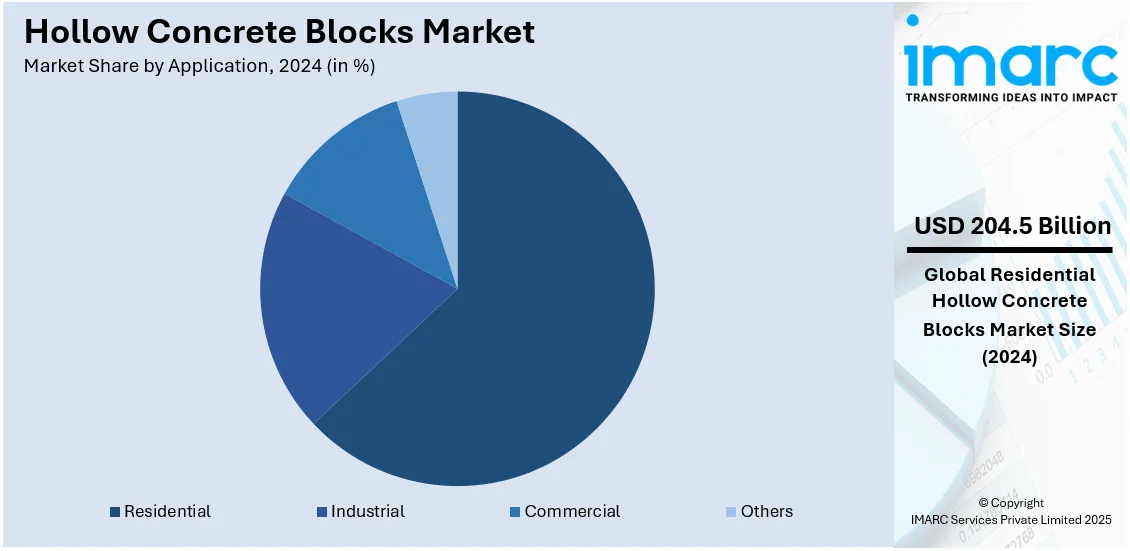

Analysis by Application:

- Industrial

- Residential

- Commercial

- Others

Residential dominated the market with around 32% of market share in 2024, fueled by increasing housing demand, urbanization, and government initiatives promoting affordable housing. Hollow concrete blocks are widely used in residential construction due to their cost-efficiency, strength, and thermal insulation properties. Their lightweight nature reduces structural load, making them ideal for multi-story buildings and modern housing projects. Sustainability concerns also boost adoption, as these blocks require less cement and generate lower carbon emissions than traditional bricks. Additionally, their fire-resistant and soundproofing qualities enhance their appeal in residential buildings. The rising trend of prefabrication and modular housing is further accelerating demand, as hollow concrete blocks support faster construction timelines while maintaining structural durability and long-term cost savings.

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, North America accounted for the largest market share of over 40.2%, supported by expanding construction activities, infrastructure modernization, and sustainability-driven building practices. Rising demand for cost-effective, durable, and energy-efficient materials in residential, commercial, and industrial sectors fuels market growth. Government investments in infrastructure, including roads, bridges, and public buildings, contribute to increased adoption. Stringent regulations promoting eco-friendly construction and LEED-certified buildings further boost demand. Additionally, the growing preference for prefabrication and modular construction accelerates the use of hollow concrete blocks due to their lightweight nature and ease of installation. The increasing focus on disaster-resistant structures, especially in hurricane- and earthquake-prone regions, also strengthens market expansion across the U.S. and Canada.

Key Regional Takeaways:

United States Hollow Concrete Blocks Market Analysis

The rising number of renovation and upgradation projects is driving the growing hollow concrete blocks adoption across the region. For instance, Americans spent USD 420 Billion in 2020 on remodeling their homes. As aging infrastructure undergoes restoration, the demand for durable and cost-effective construction materials is increasing. Hollow concrete blocks are widely used due to their structural strength, energy efficiency, and ease of installation. Commercial and residential buildings are being modernized with sustainable materials, further accelerating demand. The push for energy-efficient solutions in renovation projects has heightened the preference for hollow concrete blocks, as they provide superior insulation and durability. Additionally, the construction industry is witnessing an increasing shift toward modular building methods, boosting adoption. The trend of upgrading older buildings to meet new safety regulations and energy codes has expanded the usage of hollow concrete blocks in structural and non-structural applications. Furthermore, property owners and developers are leveraging their benefits to reduce maintenance costs and enhance building lifespan. With ongoing urban renewal initiatives and infrastructure upgrades, the growing hollow concrete blocks adoption continues to strengthen, positioning them as a preferred choice in both residential and commercial sectors.

Asia Pacific Hollow Concrete Blocks Market Analysis

The growing smart cities development is driving the growing hollow concrete blocks adoption, transforming urban landscapes with modern infrastructure. According to Ministry of Housing & Urban Affairs India, with 100 cities leading the initiative, the Smart Cities Mission has made significant progress, having completed 7,380 out of 8,075 projects, with an investment of approximately USD 17.8 Billion. The construction industry is embracing innovative and sustainable building materials, and hollow concrete blocks are gaining traction due to their versatility and cost efficiency. Smart city initiatives are fueling the demand for energy-efficient and durable materials, accelerating their integration into commercial and residential projects. The focus on eco-friendly urban development has increased interest in hollow concrete blocks, as they contribute to sustainable construction and reduced environmental impact. Large-scale projects, including residential complexes, commercial spaces, and public infrastructure, are incorporating these materials for their high load-bearing capacity and thermal insulation properties. With rapid urbanization reshaping metropolitan areas, the need for modern housing and commercial spaces is fostering increased adoption.

Europe Hollow Concrete Blocks Market Analysis

The increasing adoption of hollow concrete blocks is driven by rapid industrialization due to growing production and a strong focus on minimizing carbon footprints. According to reports, the EU's industrial production in 2021 increased by 8.5% compared with 2020. It continued with an increase in 2022 by 0.4% compared with 2021. The industrial sector is expanding, creating a need for durable and energy-efficient building materials like hollow concrete blocks. Sustainability goals encourage the use of hollow concrete blocks due to their recyclability and lower environmental impact. The efficiency of hollow concrete blocks in reducing construction waste and improving thermal insulation makes them a preferred choice for large-scale industrial and commercial developments. Stringent regulations promoting eco-friendly building solutions further drive the preference for hollow concrete blocks. Construction companies prioritize hollow concrete blocks to meet energy efficiency standards and reduce operational costs. Additionally, advancements in manufacturing techniques enhance the strength and durability of hollow concrete blocks. The long-term performance benefits of hollow concrete blocks contribute to their increased usage in industrial and infrastructural projects.

Latin America Hollow Concrete Blocks Market Analysis

The rising demand for hollow concrete blocks is influenced by the expanding residential sector, driven by the growing urban population and increasing disposable income. For instance, 85.2 % of the Latin America population is urban (565,084,260 people in 2024). The affordability and durability of hollow concrete blocks make them an essential choice for residential construction. The rapid development of housing projects enhances the market potential for hollow concrete blocks. Improved living standards contribute to the growing adoption of hollow concrete blocks in modern housing developments. Additionally, the low maintenance requirements of hollow concrete blocks support their widespread application in residential buildings. The preference for sustainable and cost-effective materials further strengthens the demand for hollow concrete blocks. The ability of hollow concrete blocks to provide enhanced thermal insulation and soundproofing benefits makes them suitable for contemporary housing needs. As urbanization continues to rise, hollow concrete blocks play a crucial role in meeting residential construction demands.

Middle East and Africa Hollow Concrete Blocks Market Analysis

The expansion of the residential and commercial sector is significantly driving the adoption of hollow concrete blocks in the construction industry. For instance, in 2023, foreign investors accounted for 45% of total commercial property transactions in Dubai. The growing urbanization and increasing commercial infrastructure projects are fueling demand, as hollow concrete blocks offer superior durability and cost-effectiveness. The rising preference for energy-efficient building materials is further supporting adoption. The need for fire-resistant and thermally insulating materials is increasing, making hollow concrete blocks a preferred choice in large-scale developments. The emphasis on faster construction timelines and reduced labour costs is accelerating market growth. The expansion of mixed-use developments and modern architectural projects is further reinforcing demand, ensuring sustained growth in the industry.

Competitive Landscape:

The hollow concrete blocks market is evolving with product innovations, strategic partnerships, and government initiatives promoting sustainable construction. Companies are launching lightweight, high-strength blocks, while collaborations enhance market expansion. Research and development focus on durability and eco-friendly solutions. Among these, government policies and R&D investments are the most common trends, driving market growth and sustainability advancements globally. The report has also analyzed the competitive landscape of the market with some of the key players being:

- Acme Brick Company (Berkshire Hathaway Inc)

- Brampton Brick

- Magicrete Building Solutions Pvt. Ltd

- Midland Brick (Buckeridge Group of Companies)

- Taylor Concrete Products Inc.

- Tristar Brick

- Block Ltd

Latest News and Developments:

- August 2024: FP McCann announced a GBP 90 Million investment to meet rising demand, including a new factory for Autoclaved Aerated Concrete Blocks and Panels. This expansion follows strong 2024 half-year sales and regulatory changes like the Future Homes Standard. Several factory extensions and new product lines will support growth, creating 100 jobs. An additional bagging line will enhance its range of specialist mortars and grouts.

- March 2024: LafargeHolcim Bangladesh introduced the Holcim block, an eco-friendly alternative to traditional bricks. The government aims to mandate concrete blocks in all projects by 2025, phasing out brick kilns. With rapid urbanization and economic growth, demand for these blocks is set to rise. Currently, 99% of bricks in Bangladesh are traditional, making concrete blocks vital for sustainable construction.

- December 2023: Betolar launched low-carbon concrete products in the UAE in partnership with Fujairah Concrete Products (FCP). FCP, a major manufacturer producing over 25 Million blocks annually, emphasizes sustainability and holds EPD certification. The initiative focuses on paving solutions using low-carbon concrete to reduce environmental impact. As part of Fujairah Building Industries, FCP reinforces its role in sustainable construction.

- April 2022: Brickworks Limited expanded into North Queensland, strengthening its manufacturing and distribution operations. The move aimed to maximize revenue and enhance market presence. This expansion supports the company’s long-term growth strategy. It reinforces Brickworks’ position in Australia’s construction sector.

- January 2022: CEMEX, S.A.B. de C.V. finalized an agreement with the U.K.’s Breedon Group plc to sell certain assets. This transaction was expected to boost market revenue and optimize business operations. The deal aligns with CEMEX’s strategic portfolio adjustments. It enhances financial strength and expands opportunities for growth.

- August 2021: Brickworks Limited acquired Southfield Corporation, the largest brick distributor in the U.S., for USD 51.1 Billion. The acquisition strengthened Brickworks’ foothold in North America. This move diversified its product offerings and market reach. It positioned Brickworks as a key player in the U.S. brick industry.

Hollow Concrete Blocks Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Products Covered | Smooth-Faced, Split-Faced |

| Applications Covered | Industrial, Residential, Commercial, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Acme Brick Company (Berkshire Hathaway Inc), Brampton Brick, Magicrete Building Solutions Pvt. Ltd, Midland Brick (Buckeridge Group of Companies), Taylor Concrete Products Inc., Tristar Brick And Block Ltd, etc |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the hollow concrete blocks market from 2019-2033.

- The hollow concrete blocks market research report provides the latest information on the market drivers, challenges, and opportunities in the global market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the hollow concrete blocks industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global hollow concrete blocks market was valued at USD 327.12 Billion in 2024.

The global hollow concrete blocks market is projected to exhibit a CAGR of 4.23% during 2025-2033, reaching a value of USD 484.25 Billion by 2033.

The global hollow concrete blocks market is driven by rapid urbanization, infrastructure expansion, and affordable housing demand. Government initiatives promoting sustainable construction, cost-effectiveness, thermal insulation, and earthquake resistance boost adoption. Technological advancements, prefabrication trends, and environmental regulations further accelerate market growth, ensuring durability and efficiency in modern building projects worldwide.

North America currently dominates the global hollow concrete blocks market, accounting for a share of 40.2%, driven by infrastructure modernization, sustainability-focused regulations, prefabrication trends, disaster-resistant construction, and government investments in roads, bridges, and public buildings.

Some of the major players in the hollow concrete blocks market include Acme Brick Company (Berkshire Hathaway Inc), Brampton Brick, Magicrete Building Solutions Pvt. Ltd, Midland Brick (Buckeridge Group of Companies), Taylor Concrete Products Inc., Tristar Brick And Block Ltd, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)