GCC 3D Printing in Healthcare Market Size, Share, Trends and Forecast by Technology, Application, Material, and Country, 2025-2033

GCC 3D Printing in Healthcare Market Size and Share:

The GCC 3D printing in healthcare market size was valued at USD 1.05 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 6.44 Billion by 2033, exhibiting a CAGR of 20.70% from 2025-2033. The market is set for rapid growth, fueled by advancements in healthcare infrastructure, increasing demand for personalized medical devices, and the drive for cost-efficiency and reduced lead times, accelerating the adoption of 3D-printed treatments and medical innovations.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 1.05 Billion |

| Market Forecast in 2033 | USD 6.44 Billion |

| Market Growth Rate (2025-2033) | 20.70% |

The rapid growth of the GCC 3D printing in healthcare market is driven by technological advancements, increased healthcare demand, and substantial government initiatives. As per the latest sources, Saudi Arabia’s Ministry of Health launched the "Regulatory Healthcare Sandbox," in June 2024, focusing on innovation in AI, IoT, biotechnology, and 3D printing to advance custom medical devices and support Vision 2030. Additionally, the technological developments in materials for 3D printing have enabled producing customized medical implants, prosthetics, and surgical models with better precision and success in medical operations. This kind of revolution in technology will allow health care providers to be able to create patient-specific solutions leading to improved patient outcomes. Increased needs for advanced medical solutions and a rising health awareness ratio are accelerating in GCC countries, due to the rise in population growth. Consequently, the healthcare sector is boosting demand for 3D printing in healthcare applications, enhancing growth prospects in the market. Government support for advanced medicines, through funding for research and development (R&D), incentives for healthcare technology, and establishment of conducive regulations, is vital for enhancing growth in this market.

Furthermore, 3D printing technology offers cost efficiency and low lead times, which is adding an impetus to the GCC healthcare market. A high rate of producing medical devices implants quickly, while minimizing material and labor inputs makes 3D printing quite appealing to manufacturers and healthcare providers alike. Traditional manufacturing methods involve long periods of production and high prices, which makes it highly difficult for health care professionals to keep up with rising demands for medical products. With 3D printing, prototyping is relatively accelerating, production cycles are faster, and cost is way down, therefore medical technology becomes highly accessible to larger populations. These economic benefits are accompanied by boosting demand for personalized medical devices, which in turn propels the adoption of 3D printing technologies in healthcare systems in the GCC region. For instance, in October 2024, the Saudi Food and Drug Authority (SFDA) launched a groundbreaking initiative to enhance diagnostic lab equipment and integrate 3D printing technology in hospitals, promoting innovation and reducing healthcare costs at the Global Health Exhibition in Riyadh.

GCC 3D Printing in Healthcare Market Trends:

Advancements in Healthcare Infrastructure

The GCC region has advanced significantly in modernizing health infrastructures and creating a facilitating environment for the widespread utilization of 3D printing in healthcare. The UAE and Saudi Arabia is also heavily investing in health technology, including 3D printing solutions, to develop better treatment outcomes. Government support to the hospitals in coordination with the private sector initiatives helps 3D printing for medical purposes such as prosthetics, orthotics, and surgical planning. This investment in advanced health care also leads to better patient care while propelling demand for innovative and customizable health care solutions. Improved health care policies and regulations also ensure a stronger market for 3D printing, making the space available for local as well as global players. These advancements are expected to keep accelerating the adoption of 3D printing technologies across the region.

Growing Demand for Medical Devices

The growing demand for personalized and customized medical devices is one of the main factors driving the GCC 3D printing in healthcare market. For example, Ad Line Media, a leader in 3D printing services, launched innovative healthcare solutions in Saudi Arabia in September 2024. These include customized prosthetics, surgical models, and dental applications aligned with Vision 2030 goals. Furthermore, as patients intensely seek individualized treatments, 3D printing allows for the creation of tailor-made prosthetics, implants, and anatomical models. This demand is being fueled by the rising prevalence of chronic diseases, an aging population, and a higher incidence of lifestyle-related health conditions. Hospitals and clinics in the GCC are adopting 3D printing technologies to produce accurate, patient-specific solutions that improve treatment precision. The ability to quickly produce customized medical devices that fit a patient’s unique needs is revolutionizing the healthcare industry. The demand for personalized healthcare solutions is expected to continue growing, further propelling the market for 3D-printed medical devices in the region.

Cost-Efficiency and Reduced Lead Times

The cost-saving and reduced lead times of 3D printing in healthcare are the reasons for its adoption across the GCC region. Traditional manufacturing methods for medical devices often involve high production costs and long waiting periods, especially when there is a requirement for customization. 3D printing, however, allows rapid prototyping and on-demand production, reducing both costs and delivery times. This efficiency is highly advantageous for a healthcare market wherein access to timely medical treatments and products is of essence. Furthermore, the material waste count reduces, ultimately bringing about cost reduction to the system of production. Moreover, as health care facilities in the GCC continue toward the reduction of operational expenditure and improved results making low-cost, speedy solutions enabled by 3D printing which are becoming a differentiating factor in boosting its deployment.

GCC 3D Printing in Healthcare Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the GCC 3D printing in healthcare market, along with forecasts at the country and regional levels from 2025-2033. The market has been categorized based on technology, application, and material.

Analysis by Technology:

- Stereo Lithography

- Deposition Modeling

- Electron Beam Melting

- Laser Sintering

- Jetting Technology

- Laminated Object Manufacturing

- Others

Stereolithography (SLA) is a laser technology through which liquid resin gets hardened and forms solid 3D objects with high precision and resolution details. It is commonly applied for prototype production in health for exact dental implants, oral surgeons, and guides surgery in healthcare. This makes the SLA suitable for generating solutions related to medical solutions custom for patients, in ensuring effective products with appropriate personal treatments, and improves medical practice.

Analysis by Application:

- Medical Implants

- Prosthetics

- Wearable Devices

- Tissue Engineering

- Others

With 3D printing, personalized medical implants-the orthopedic and dental ones-in the anatomy of any patient are produced. Its use results in higher accuracy, biocompatibility, and higher production speeds compared to other similar technologies and, therefore improves surgical results. Functionally enhanced and more indispensable within modern medicine, 3D printing-produced implants continue to gain importance in solving individual, effective solutions to patients' needs.

Analysis by Material:

- Metal and Alloy

- Polymer

- Others

Polymers like PLA, ABS, and PEEK have been versatile materials for 3D printing, applied to lightweight flexible medical applications, including prosthetics, surgical guides, and anatomical models. Biocompatible polymers, especially hydrogels, play a major role in tissue engineering and drug delivery systems, providing more effective treatments for patients as well as overall healthcare benefits.

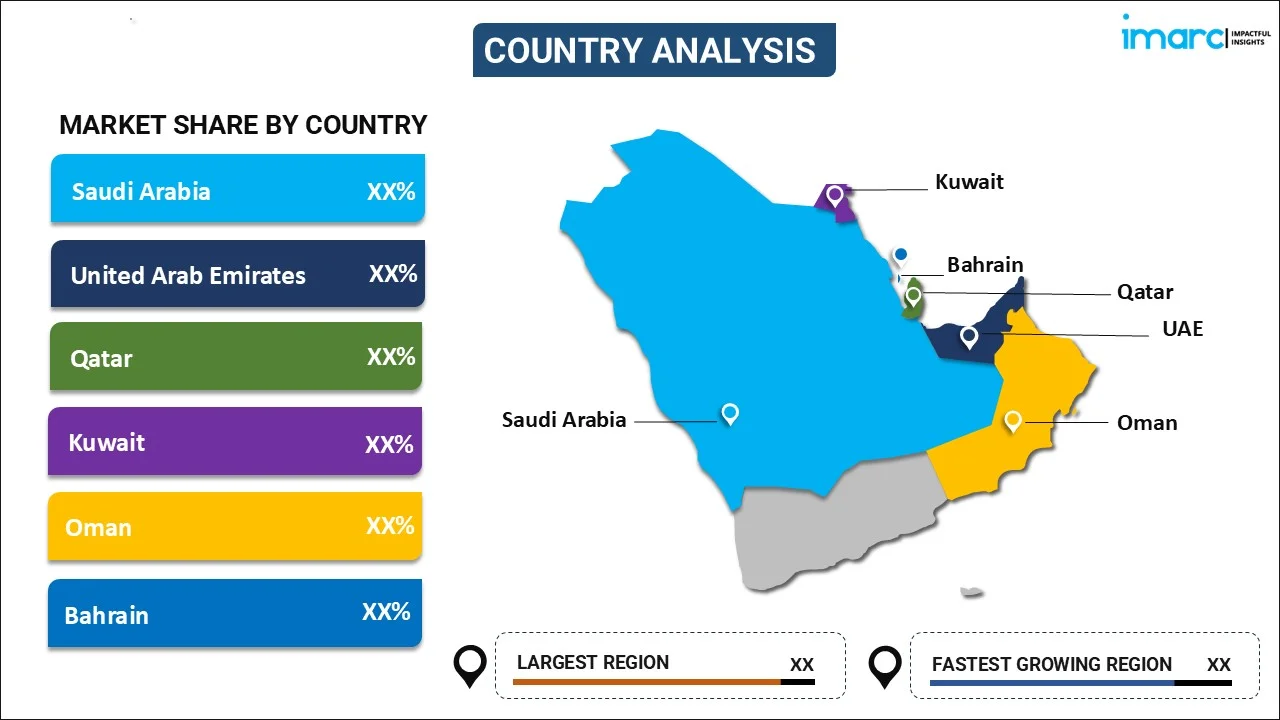

Country Analysis:

- Saudi Arabia

- UAE

- Qatar

- Kuwait

- Oman

- Bahrain

Saudi Arabia is highly leading in adopting 3D printing in healthcare, pushed by its Vision 2030 initiative. Investments are being made in advanced medical technologies and collaborations with international healthcare firms to accelerate production of implants, prosthetics, and surgical tools- all in response to the surge in demand for personalized medical solutions.

The UAE is one of the leading countries in GCC healthcare innovation, and initiatives in 3D printing are supported by government policies such as the Dubai 3D Printing Strategy. Applications include custom prosthetics, dental devices, and bioprinting for tissue engineering, making the UAE a hub for advanced medical manufacturing.

Saudi Arabia is highly leading in adopting 3D printing in healthcare, pushed by its Vision 2030 initiative. Investments are being made in advanced medical technologies and collaborations with international healthcare firms to accelerate production of implants, prosthetics, and surgical tools- all in response to the surge in demand for personalized medical solutions.

The UAE is one of the leading countries in GCC healthcare innovation, and initiatives in 3D printing are supported by government policies such as the Dubai 3D Printing Strategy. Applications include custom prosthetics, dental devices, and bioprinting for tissue engineering,

Qatar is rapidly integrating 3D printing technologies in its health sector, targeting medical education and patient-specific applications. The country invests in 3D bioprinting research for tissue engineering and regenerative medicine while using 3D-printed anatomical models for surgical planning and training.

Kuwait adopts 3D printing technology for the care of patients to provide improved implants, prosthetics, and anatomical models to them. The region is looking forward to enhancing medical infrastructure through its modernization plan, further collaboration with relevant technology vendors for the proper accessibility and efficiency of highly advanced 3D printing solutions.

Oman is gradually embracing 3D printing in healthcare as it addresses the local medical challenges, which include cheap prosthetics and implants. Oman is shifting its focus on making accessible advanced treatments with the use of 3D printing for the low-cost production of medical devices and surgical tools in enhancing patient care.

Bahrain is embracing 3D printing within its healthcare environment by engaging with international companies and domestic innovation centers. Examples of applications include dental implants, prosthetics, and models for educational use. The country is further developing its capabilities by taking up biocompatible materials and applying 3D printing for surgical accuracy and simulation, making the UAE a hub for advanced medical manufacturing.

Key Regional Takeaways:

KSA (Saudi Arabia) 3D Printing in Healthcare Market Analysis

The growth of the 3D printing in healthcare market is mainly driven by investment in healthcare infrastructure and innovations in Saudi Arabia. The growth initiative of the government-its Vision 2030 program-considers improving healthcare services, also raising the adoption of leading-edge technologies such as 3D printing to treat individuals with personalized medical care such as prosthetics and implants. Additionally, there is increasing demand for high-quality medical devices and custom healthcare solutions, and 3D printing technology facilitates these through faster production and cost reduction. The Saudi drive for medical tourism and increased patient-specific treatment demand have been on the rise. Moreover, public and private collaboration is driving up research and development in 3D printing, leading to improved health care and enhancing the country's position as a regional leader in health care.

UAE 3D Printing in Healthcare Market Analysis

There are rapid advancements happening in the 3D printing in healthcare market in the UAE, due to the focus of the government on digital transformation and smart healthcare. UAE Vision 2021 highlights innovative technologies in health care systems with a greater importance placed on 3D printing, on personalized medicine and medical device development. This includes the use of the latest technologies such as 3D printing in prosthetics and surgical models by the Dubai Health Authority. International and regional players are thus attracted to the emirate. High-quality healthcare services, combined with the UAE's efforts to become a global medical hub, further contribute to adoption of 3D printing. With robust healthcare infrastructure and support to startups, the UAE provides fast adoption of advanced healthcare technologies and is an attractive market for investment in 3D printing.

Competitive Landscape:

The competitive landscape of the GCC 3D printing in healthcare market is marked with rapid technological advancements, heavy investments in research and development (R&D), and growing collaboration among healthcare providers and technology innovators. Companies are highly focused on offering customized solutions by adopting advanced materials such as biocompatible polymers and metals for implants, prosthetics, and surgical tools. Emphasis on precision, cost-effectiveness, and patient-specific applications drives the innovation. Regional governments also have been very active in the promotion of 3D printing through initiatives and infrastructure development, thus further increasing the competition. Players in the market diversify their portfolios in areas such as bioprinting, wearable devices, and anatomical models. The use of 3D printing in education, training, and regenerative medicine contributes to dynamic competition, leading to enhancement in technology and service delivery.

The report provides a comprehensive analysis of the competitive landscape in the GCC 3D printing in healthcare market with detailed profiles of all major companies, including:

- 3D Systems Inc.

- Renishaw PLC

- Materialise NV

- Stratasys Ltd

- Fathom Manufacturing

- General Electric

- 3D Systems Corporation

- Carbon, Inc.

- Formlabs

Latest News and Developments:

- In December 2024, Materialise NV launched its integrated Mimics platform, aimed at enhancing personalized healthcare through 3D printing. This unified platform improves collaboration, segmentation, and design efficiency, enabling medical device companies and hospitals worldwide to deliver more customized and efficient patient care.

- October 2024: The Saudi Food and Drug Authority (SFDA) launched an initiative to enhance diagnostic laboratory equipment and promote 3D printing in hospitals during the Global Health Exhibition 2024 in Riyadh. This initiative aims to foster innovation and research while reducing costs for medical facilities and strengthening the national industry.

GCC 3D Printing in Healthcare Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | USD Billion |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereo Lithography, Deposition Modeling, Electron Beam Melting, Laser Sintering, Jetting Technology, Laminated Object Manufacturing, Others |

| Application Covered | Medical Implants, Prosthetics, Wearable Devices, Tissue Engineering, Others |

| Material Covered | Metal and Alloy, Polymer, Others |

| Countries Covered | Saudi Arabia, UAE, Qatar, Kuwait, Oman, and Bahrain |

| Companies Covered | 3D Systems Inc., Renishaw PLC, Materialise NV, Stratasys Ltd, Fathom Manufacturing, General Electric, 3D Systems Corporation, Carbon, Inc., Formlabs |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the GCC 3D printing in healthcare market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the GCC 3D printing in healthcare market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the GCC 3D printing in healthcare industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

3D printing in healthcare refers to the use of additive manufacturing technologies to create medical devices, prosthetics, implants, and tissue models. It enables the production of customized products tailored to individual patient needs. Applications include personalized implants, prosthetic limbs, surgical tools, anatomical models for planning, and even bioprinting for tissue regeneration. This innovation enhances precision, reduces costs, and improves patient outcomes.

The GCC 3D printing in healthcare market was valued at USD 1.05 Billion in 2024.

IMARC estimates the GCC 3D printing in healthcare market to exhibit a CAGR of 20.70% during 2025-2033.

The key factors driving the GCC 3D printing in healthcare market include advancements in healthcare infrastructure, increasing demand for personalized medical devices, the rise of cost-efficient production methods, and government initiatives supporting medical innovations. These factors, combined with the growing adoption of 3D printing technologies in medical fields, are fueling market growth.

In 2024, Stereo Lithography represented the largest segment by technology, driven by its ability to produce highly detailed and precise medical models. SLA is widely used for creating accurate surgical guides, prototypes, and patient-specific medical solutions.

Medical implants lead the market by application owing to the increasing demand for personalized and customized healthcare solutions. 3D printing enables the production of precise, biocompatible implants, improving surgical outcomes and reducing recovery times for patients across various medical fields.

Polymers is the leading segment by material, driven by their versatility and biocompatibility. Polymers, such as PLA, PEEK, and ABS, are commonly used in 3D printing for producing lightweight medical implants, prosthetics, surgical guides, and anatomical models with high precision.

Some of the major players in the GCC 3D printing in healthcare market include 3D Systems Inc., Renishaw PLC, Materialise NV, Stratasys Ltd, Fathom Manufacturing, General Electric, 3D Systems Corporation, Carbon Inc., Formlabs, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)