Face Shield Market Size, Share, Trends and Forecast by Material Type, Tier Type, Type, Product Type, End User, and Region, 2025-2033

Face Shield Market Size and Share:

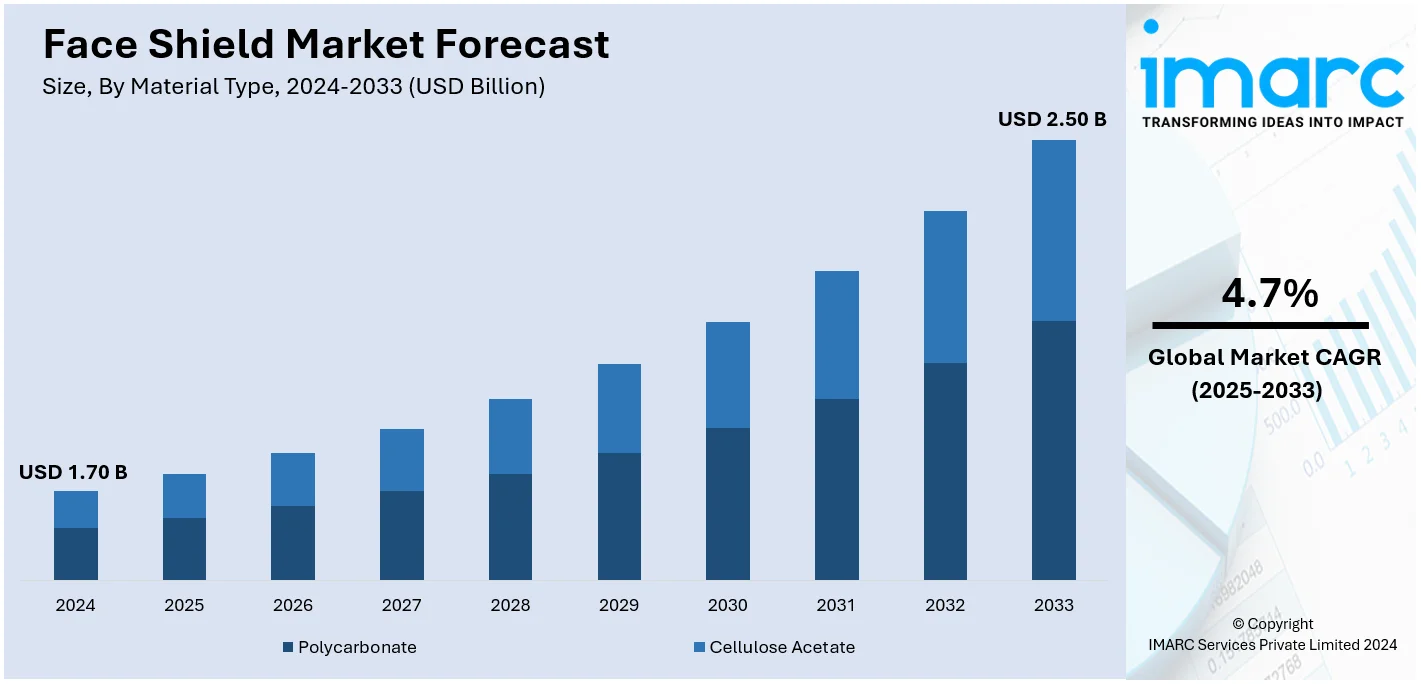

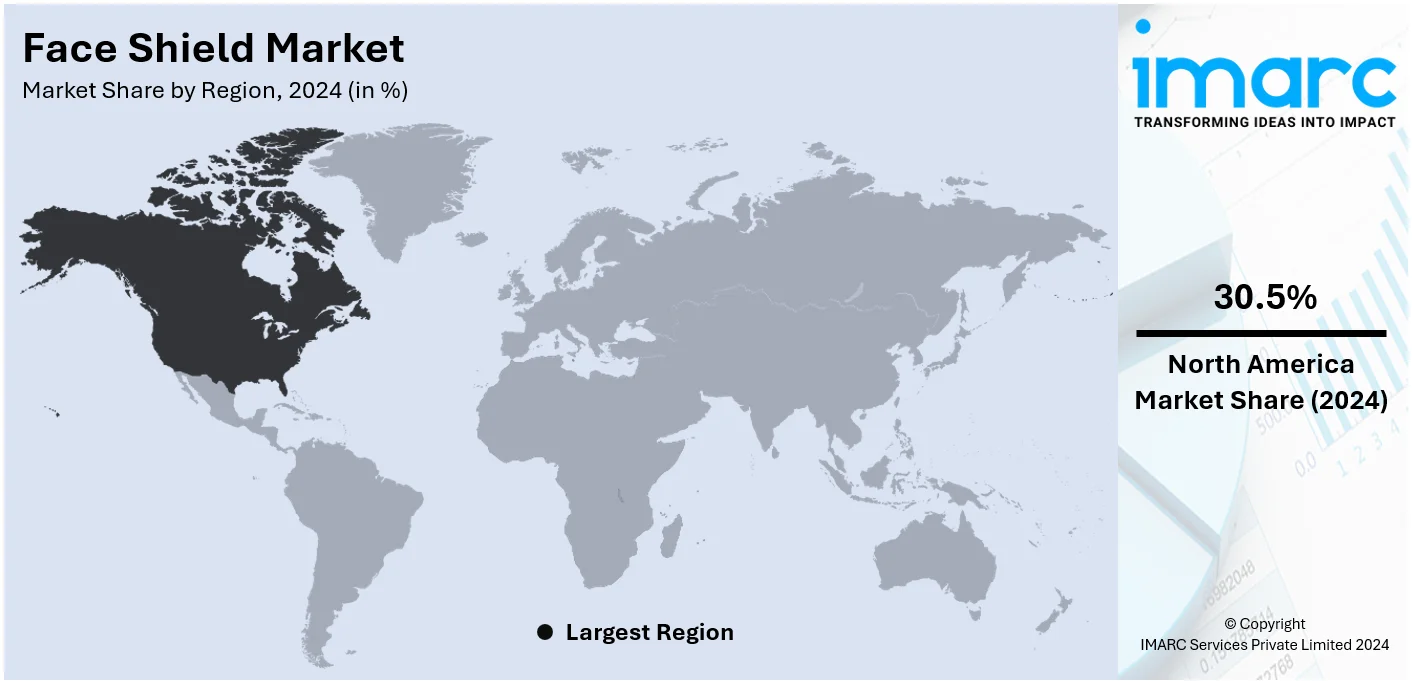

The global face shield market size was valued at USD 1.70 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 2.50 Billion by 2033, exhibiting a CAGR of 4.7% during 2025-2033. North America currently dominates the market, holding a significant market share of over 30.5% in 2024. The rising demand for personal protective equipment, increased health awareness, workplace safety regulations, and advancements in material technology are some of the factors propelling the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 1.70 Billion |

|

Market Forecast in 2033

|

USD 2.50 Billion |

| Market Growth Rate (2025-2033) | 4.7% |

The market for face shields primarily relies on the increasing awareness about PPE due to rampant outbreak of pandemics such as COVID-19, which increases the demand for PPE. Face shields in the health sector are required because of preventing infections, besides its application in manufacturing, building, and chemical handling for protection from splashes and debris. Strict workplace safety laws have been increasing all over the world, which catalyzes to face shields adoption. Also, recent advancements in materials, becoming clear, robust, yet lightweight, make the products more comfortable and functional for higher usage. Moreover, advanced healthcare infrastructure in developing countries and the growing awareness about occupational hazards are acting as another major growth-inducing factors. Furthermore, the market for face shields is still being positively impacted by the growing demand for recyclable and environmentally friendly PPE equipment.

The face shield market in the United States has been pushed forward by an increased need for personal protective equipment across healthcare industry. Widespread awareness of infection control generated by the COVID-19 pandemic ensured its broad application in healthcare settings. With the implementation of strict occupational safety regulations of organizations, such as OSHA, the use of face shields has become mandatory in construction industries, manufacturing industries, and chemical handling. For instance, The U.S. Department of Labor's Occupational Safety and Health Administration announced in December 2023 that it is replacing conventionally used hard hats used by its employees with more modern safety helmets to protect them better while on inspection sites. In line with this, OSHA in November 2023 published a Safety and Health Information Bulletin discussing significant differences between traditional hard hats and newer safety helmets, plus advances in design, materials, and other features to protect the entire head of the worker. Modern safety helmets now come with face shields or goggles that offer protection against projectiles, dust, and chemical splashes. Consumer preference is motivated by improved comfort and functionality driven by improvements in lightweight, robust materials, and reusable face shields.

Face Shield Market Trends:

Growing Investments in the Healthcare Sector

The expanding healthcare infrastructure, particularly in emerging economies, drives the demand for protective equipment, including face shields. Governments and private sectors are investing heavily in improving healthcare facilities and ensuring sufficient supplies of PPE to protect medical professionals. With growing healthcare needs, recurring disease outbreaks, and rising awareness of infection prevention, face shields have become an essential protective tool in hospitals, clinics, and other healthcare facilities, supporting overall market growth globally. According to the India Brand Equity Foundation (IBEF), the hospital market in India is expected to reach USD 193.59 billion by 2032, growing at a compound annual growth rate (CAGR) of 8.0% from its 2023 valuation of USD 98.98 billion. Face shields are essential in healthcare for protecting medical professionals from infectious droplets, splashes, and bodily fluids during patient care or surgeries.

Rising Demand from Construction Industry

In the construction industry, face shields protect workers from flying debris, dust, and sparks during tasks such as cutting, grinding, or drilling. Compliance with workplace safety regulations, such as OSHA guidelines, makes protective gear mandatory on job sites. The rising product utilization in the construction industry to provide general protection against dirt and debris and special protection during welding applications against spark, radiation, and intense heat, is positively influencing the market growth. According to industry reports, the construction industry in 2024 experienced a 10% increase in nominal value added and a 12% rise in gross output, with spending surpassing USD 2 Trillion. As employment reached a record 8.3 Million, the growing industry presents an opportunity for face shield adoption, enhancing safety amidst ongoing workforce shortages.

Stringent Workplace Safety Regulations

The increasing demand for face shields has been driven by government-mandated workplace safety regulations, particularly in sectors like construction, manufacturing, and chemicals. Agencies like OSHA mandate protective gear to minimize occupational hazards, including exposure to debris, chemicals, and harmful particles. Compliance with such regulations ensures worker safety, reduces workplace injuries, and promotes the adoption of face shields as a critical component of protective equipment in hazardous work environments, boosting market growth worldwide. According to CDRH's A-list, which was released on October 10, 2024 (CDRH Proposed Guidances for Fiscal Year 2025 (FY2025) | FDA), the FDA plans to release a draft guidance for public comment in FY2025 titled "Enforcement Discretion Policy for Premarket and Other Requirements for NIOSH-Approved Air Purifying Respirators." This could impact development plans and requests for FDA feedback, so companies interested in creating NIOSH-approved respirators should be aware of this.

Face Shield Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global face shield market, along with forecasts at the global, regional, and country levels from 2025-2033. The market has been categorized based on material type, tier type, type, product type, and end user.

Analysis by Material Type:

- Polycarbonate

- Cellulose Acetate

Polycarbonate stand as the largest component in 2024, holding around 56.7% of the market. Polycarbonate holds the largest share in the face shield market due to its exceptional properties, including high impact resistance, optical clarity, and lightweight design. It provides superior protection against flying debris, splashes, and harmful particles, making it ideal for industries like healthcare, construction, and manufacturing. Its scratch-resistant and anti-fog capabilities enhance visibility, ensuring user comfort during extended use. Polycarbonate is also durable, shatterproof, and easy to mold, allowing for innovative and ergonomic designs. Additionally, its cost-effectiveness and availability make it a preferred material for producing reusable and reliable face shields, driving its widespread adoption in safety and protective equipment markets.

Analysis by Tier Type:

- Premium

- Medium

- Value

Premium-tier face shields hold the largest share in the market due to their superior features, such as enhanced comfort, durability, and advanced protection. These shields often use high-quality materials like anti-fog and scratch-resistant coatings, offering clearer visibility and extended usability. Premium shields are designed for optimal fit, ensuring comfort during prolonged wear, especially in healthcare and industrial settings. They also provide better protection against a wide range of hazards, making them highly sought after in demanding environments. Additionally, consumers are increasingly willing to invest in high-end PPE for superior safety, reliability, and overall performance, driving the premium segment's growth.

Analysis by Type:

- Disposable

- Reusable

Reusable face shields hold the largest share in the market due to their cost-effectiveness, sustainability, and long-term value. As consumers and businesses prioritize eco-friendly solutions, reusable face shields offer a more sustainable alternative to single-use products. Their durability and ability to withstand multiple cleanings make them a practical investment, especially in industries with high PPE usage like healthcare, construction, and manufacturing. Additionally, reusable face shields align with growing environmental awareness and reduce waste, further driving demand. Their versatility, combined with ease of use and maintenance, positions them as the preferred choice for long-term protective gear across various sectors.

Analysis by Product Type:

- Half Face Shield

- Full Face Shield

Full face shield electronics leads the market with around 61.5% of the market share in 2024. Full-face shields hold the largest share in the face shield market due to their comprehensive protection, covering the entire face, including the eyes, nose, and mouth. This all-encompassing coverage is essential in high-risk environments like healthcare, manufacturing, and construction, where exposure to hazardous materials, debris, or infectious agents is prevalent. Full-face shields offer better safety against splashes, airborne particles, and impact, while ensuring clear visibility. Their comfort, combined with enhanced protection, makes them the preferred choice for industries prioritizing both safety and long-term use, driving the demand for full-face shields across various sectors.

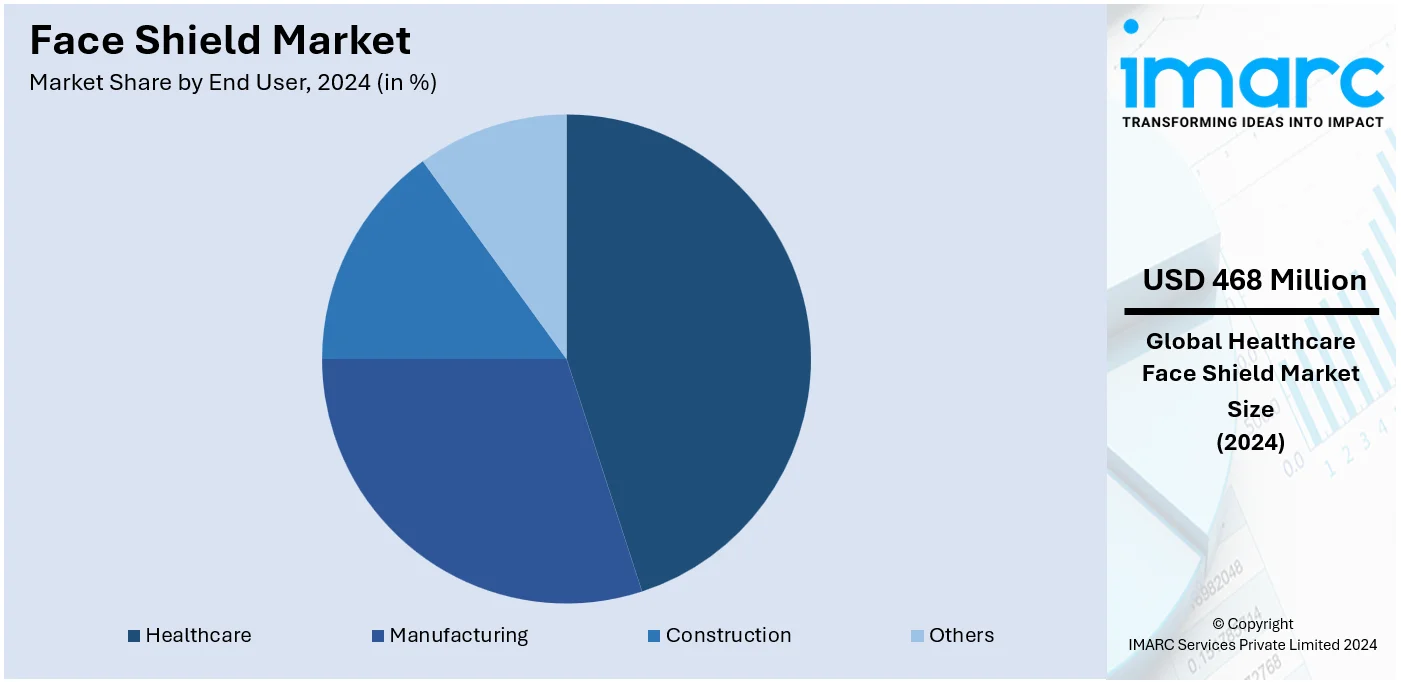

Analysis by End User:

- Healthcare

- Manufacturing

- Construction

- Others

Healthcare leads the market with around 27.5% of the market share in 2024. Healthcare holds the largest share in the face shield market due to the critical role face shields play in protecting medical professionals from exposure to infectious diseases, bodily fluids, and airborne particles. The COVID-19 pandemic significantly increased the demand for face shields in hospitals, clinics, and laboratories. Healthcare workers, including doctors, nurses, and lab technicians, rely on face shields as part of their personal protective equipment (PPE) to prevent contamination while maintaining clear visibility. The increasing focus on infection control, safety standards, and workplace health further drives the adoption of face shields, solidifying the healthcare sector's dominance in the market.

Regional Analysis:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

In 2024, North America accounted for the largest market share of over 30.5%. In North America, several factors are driving the face shield market. The ongoing emphasis on health and safety in healthcare, driven by the COVID-19 pandemic, has heightened the demand for personal protective equipment (PPE), including face shields. Stringent workplace safety regulations, particularly in industries like construction, manufacturing, and healthcare, have made face shields essential for protecting workers from physical hazards and infectious agents. Additionally, advancements in materials have led to the development of more durable, comfortable, and cost-effective face shields, encouraging widespread adoption. Increased awareness of workplace safety and government initiatives to enhance PPE availability further support the market. Moreover, North America's robust healthcare infrastructure and the focus on infection prevention are pivotal factors sustaining the growth of the face shield market.

Key Regional Takeaways:

United States Face Shield Market Analysis

In 2024, the United States accounted for the market share of over 80.10%. The demand for protective equipment in medical settings is driven by increased awareness of safety protocols, high standards in healthcare infrastructure, and stringent guidelines promoting safety for professionals and patients. According to American Medical Association, health expenditure in the U.S. rose by 4.1% in 2022 to USD 4.5 Trillion, aligning with pre-pandemic growth rates, while rebounding demand for medical goods and services highlights the expanding healthcare infrastructure, boosting demand for protective face shields. With frequent adoption of advanced materials, protective gear ensures clear visibility and durable performance in surgical and diagnostic applications. The region benefits from strong government policies incentivizing innovations in medical devices. Additionally, growing outpatient services and specialized clinics encourage the use of protective solutions for enhanced safety. These items are commonly employed in dental practices, emergency rooms, and laboratories. Urban regions see heightened usage in teaching hospitals and clinical research centres. The equipment’s integration into daily medical routines reflects a commitment to safeguarding health professionals during invasive procedures, reducing the spread of infections. Advancements in anti-fogging technology further enhance usability in high-humidity environments.

Asia Pacific Face Shield Market Analysis

The surge in demand from industrial sectors reflects the rapid growth of manufacturing hubs. These regions prioritize worker safety in high-risk industries such as welding, chemical handling, and electronics assembly. For instance, India's manufacturing sector, contributing 15-16% to GDP, is poised for growth as government initiatives align with global manufacturers' diversification needs, boosting opportunities for face shield production to meet rising safety demands. The production environment requires durable protection against sparks, splashes, and debris, encouraging innovation in lightweight and ergonomic designs. Additionally, high-volume industrial activities stimulate the use of shields in automotive and machinery assembly lines. Favorable policies supporting local manufacturing and export-oriented industries amplify their adoption. Flexible production capabilities allow the creation of cost-efficient models suitable for diverse manufacturing processes, ranging from textile to precision engineering.

Europe Face Shield Market Analysis

The construction industry sees substantial usage of safety gear due to stringent regulatory standards emphasizing worker safety on sites. Face shields items are vital in high-risk tasks like cutting, grinding, and painting, where protection against particulate matter and chemicals is critical. According to reports, the European Union's construction sector showed a 1.8% monthly growth in February 2024, with engineering structures rising 3.6%, highlighting potential for enhanced demand for face shields in construction safety. Austria (+9.3%) and Germany (+7.9%) led growth, showcasing robust opportunities for face shields adoption. Widespread urban development and large-scale infrastructure projects fuel the adoption of safety solutions. Regions with older cities undergoing restoration also show increased demand, especially in preserving historical buildings while ensuring worker safety. Innovations in scratch-resistant and anti-UV coatings enhance usability in outdoor settings. Specialized shields designed for visibility in low-light environments find applications in tunnelling and bridge construction.

Latin America Face Shield Market Analysis

The Latin American face shield market is experiencing growth due to the expansion of the end use sectors. Increasing healthcare infrastructure investments, driven by government initiatives and rising public health awareness, are boosting the demand for protective equipment like face shields. According to the National Library of Medicine, A longitudinal study in Brazil revealed 9.5 Million hospitalizations and 1.17 Million deaths due to respiratory diseases from 2008 to 2021, with a national fatality rate of 12.32%. Similarly, the construction sector’s growth, fuelled by urbanization and infrastructure projects, requires safety gear to ensure worker protection. In manufacturing, stringent workplace safety regulations are encouraging the adoption of face shields to mitigate risks from machinery and chemical exposure. These developments not only drive market demand but also highlight the critical role of face shields in enhancing safety standards, reducing workplace hazards, and supporting compliance with regional safety protocols.

Middle East and Africa Face Shield Market Analysis

The booming real estate sector and oil industry prioritize worker safety during construction and maintenance activities. According to ITA, Saudi Arabia holds 17% of global petroleum reserves, producing 11.5 mmbpd of crude oil in 2022, and its low-carbon oil enhances face shield requirements to ensure worker safety in high-output, energy-intensive conditions. Protective equipment is critical in shielding workers from environmental hazards like dust, splashes, and debris. The rise of energy projects, including oil refineries and renewable energy installations, enhances demand for robust safety gear to ensure compliance with stringent occupational safety regulations. Specialized solutions designed for extreme weather conditions or chemical exposure are increasingly adopted to meet the specific needs of diverse industries. Additionally, regional partnerships and technology transfers streamline access to innovative safety solutions, driving their adoption across critical sectors.

Competitive Landscape:

The face shield market is highly competitive, with key players including 3M, Honeywell, Kimberly-Clark, and Ansell, offering a wide range of protective solutions across various industries. These companies focus on product innovation, quality, and compliance with safety standards to maintain market leadership. Manufacturers are increasingly adopting advanced materials like polycarbonate and introducing features such as anti-fog coatings, adjustable straps, and ergonomic designs to improve comfort and protection. Additionally, regional players and startups are gaining market share by offering cost-effective and eco-friendly alternatives. The market is also driven by growing demand in healthcare, construction, and industrial sectors, further intensifying competition.

The report has also analysed the competitive landscape of the market with some of the key players being:

- 3M Company

- Alpha Pro Tech Ltd.

- Casco Bay Molding

- Gateway Safety Inc.

- Honeywell International Inc.

- JBC Technologies Inc.

- KARAM Safety Private Limited

- Key Surgical Inc. (Steris plc)

- Medline Industries LP

- MSA Safety Incorporated

- Precept Medical Products Inc. (Aspen Surgical Products Inc.)

- Prestige Ameritech

- Pyramex Safety Products LLC

Latest News and Developments:

- December 2024: WeeTect has unveiled advanced face shields featuring cutting-edge anti-scratch and anti-fog technology, suitable for diverse industrial applications. Meeting ANSI Z87.1, EN166, and EN170 standards, these shields ensure superior optical performance while enhancing safety. Priced for accessibility, these shields aim to revolutionize personal protective equipment.

- June 2024: STUDSON has unveiled three innovative face shields for its SHK-1 Full Brim Safety Helmet, including Arc Flash Tint, Clear, and Shade 5 Green Tint options. Designed in collaboration with Paulson Manufacturing, these shields seamlessly integrate with the ANSI Z89.1 Type II helmet, eliminating the hassle of custom fittings or switching PPE. Ideal for welding and safety applications, the shields enhance protection and efficiency.

- May 2024: Pro-Lite Technology has introduced the Laservision FS1 Laser Welding Safety Face Shield, a lightweight (386g) industrial visor certified to EN207 standards. Designed to protect both eyes and face from laser radiation, it caters to the growing use of handheld laser welders. Priced at approximately USD 50, the FS1 offers enhanced safety and comfort for industrial applications.

- January 2024: Qorvo Team Wendy introduced tactical face shields at the SHOT Show 2024, enhancing first responder safety during riots and disturbances. Alongside, they unveiled a prototype rifle-rated helmet and a non-ballistic nape guard. These innovations aim to strengthen protective gear in high-risk scenarios, priced to cater to the global market, converting roughly into USD for accessibility.

- February 2021: FIGS has unveiled its High-Def Face Shield, a lightweight, anti-fog shield designed for healthcare professionals. This innovative PPE offers 24/7 comfort and clear visibility, ensuring functionality and style. Co-founder Heather Hasson highlights the premium shield as part of FIGS' commitment to enhancing the performance and confidence of healthcare workers.

- November 2020: Purifas® has launched its Face Shield™ in the United Kingdom, following success in Australia and New Zealand. Clinically proven to reduce bacterial transmission, it offers full coverage for face holes in clinical settings. The innovation supports therapists in enhancing hygiene and client care globally.

Face Shield Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Material Types Covered | Polycarbonate, Cellulose Acetate |

| Tier Types Covered | Premium, Medium, Value |

| Types Covered | Disposable, Reusable |

| Product Types Covered | Half Face Shield, Full Face Shield |

| End Users Covered | Healthcare, Manufacturing, Construction, and Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | 3M Company, Alpha Pro Tech Ltd., Casco Bay Molding, Gateway Safety Inc., Honeywell International Inc., JBC Technologies Inc., KARAM Safety Private Limited, Key Surgical Inc. (Steris plc), Medline Industries LP, MSA Safety Incorporated, Precept Medical Products Inc. (Aspen Surgical Products Inc.), Prestige Ameritech, Pyramex Safety Products LLC, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the face shield market from 2019-2033.

- The face shield market research report provides the latest information on the market drivers, challenges, and opportunities in the global market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the face shield industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

A face shield is a transparent, plastic protective barrier worn over the face to safeguard against splashes, droplets, or debris. It typically covers the entire face, including the eyes, nose, and mouth, and is commonly used in healthcare, construction, and industrial settings to reduce exposure to harmful substances.

The face shield market was valued at USD 1.70 Billion in 2024.

IMARC estimates the global face shield market to exhibit a CAGR of 4.7% during 2025-2033.

The key factors driving the global face shield market are increasing demand for personal protective equipment (PPE), rising health awareness, stringent workplace safety regulations, and the need for infection control in healthcare. Growth in industrial sectors, recurring pandemics, and innovations in lightweight, durable materials further contribute to market expansion globally.

According to the report, polycarbonate represented the largest segment by material type due to its high impact resistance, optical clarity, lightweight design, durability, and cost-effectiveness.

Premium leads the market by tier type due to superior comfort, durability, enhanced protection, advanced features, and higher demand in critical industries.

Reusable leads the market by type due to cost-effectiveness, sustainability, durability, long-term value, and growing demand for eco-friendly, practical solutions.

Full-face shields leads the market by product type due to superior protection, covering the entire face, and offering enhanced safety in hazardous environments.

Healthcare leads the market by end user due to the high demand for face shields to protect medical professionals from infections and hazards.

On a regional level, the market has been classified into North America, Asia Pacific, Europe, Latin America, and Middle East and Africa, wherein North America currently dominates the global market.

Some of the major players in the global face shield market include 3M Company, Alpha Pro Tech Ltd., Casco Bay Molding, Gateway Safety Inc., Honeywell International Inc., JBC Technologies Inc., KARAM Safety Private Limited, Key Surgical Inc. (Steris plc), Medline Industries LP, MSA Safety Incorporated, Precept Medical Products Inc. (Aspen Surgical Products Inc.), Prestige Ameritech and Pyramex Safety Products LLC.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)