Europe Sandwich Panels Market Size, Share, Trends and Forecast by Type, Skin Material, Technology, Application, End Use, and Country, 2025-2033

Europe Sandwich Panels Market Size and Share:

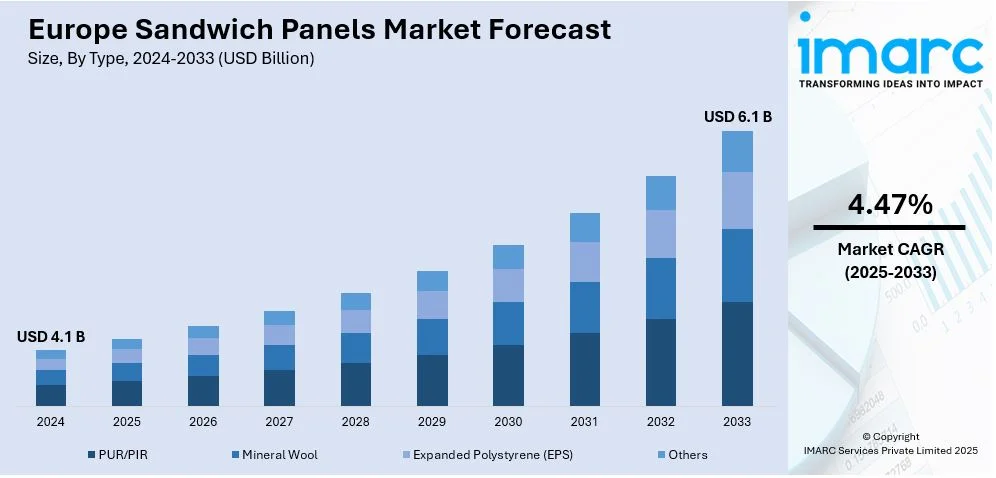

The Europe sandwich panels market size was valued at USD 4.1 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 6.1 Billion by 2033, exhibiting a CAGR of 4.47% from 2025-2033. The market is witnessing significant growth due to the escalating demand for energy-efficient buildings and the growing emphasis on sustainability and green construction. Moreover, the rise of prefabricated and modular construction, technological advancements in insulation, and increasing focus on industrial and commercial applications are expanding the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 4.1 Billion |

|

Market Forecast in 2033

|

USD 6.1 Billion |

| Market Growth Rate (2025-2033) | 4.47% |

The increasing need for energy-efficient buildings is also a key driving force. There is a high increase in the cost of energy, and this, coupled with rising environmental concerns, has led to a marked trend towards constructing energy-efficient structures in Europe. Among the solutions applied to reduce energy consumption in both residential and commercial buildings, there are sandwich panels, which excel in insulation performance. For example, the Ukrainian insulation market saw the domestic sales of insulated sandwich panels by construction company Rauta grow 15% in the first half of 2024. These panels help maintain an indoor temperature, cutting down on the needs for heating and cooling, ultimately lowering the bill of energy generated. The trend is highly visible in green buildings and retrofitting of existing buildings to respect the regulations set for saving energy and meeting the efficiency standards set for buildings.

The growing emphasis on sustainability and green construction is fueling the market for sandwich panels. Governments and regulatory bodies across Europe have implemented stringent environmental policies that encourage the use of sustainable materials in construction. Sandwich panels, which offer reduced environmental impact due to their lightweight nature and ability to be recycled, align with these objectives. For instance, in 2024, Kingspan / Invespanel became the first sandwich panel producer in Spain and Portugal to use ArcelorMittal's XCarb recycled steel, reducing carbon footprint with 100% renewable energy and 75% scrap steel. Additionally, their ease of installation reduces construction time and associated waste, further supporting the sustainability goals of builders and developers in the region.

Europe Sandwich Panels Market Trends:

Rise of Prefabricated and Modular Construction

Prefabrication and modular construction are becoming increasingly popular across Europe, particularly in response to labor shortages and the need for quicker construction timelines. Sandwich panels are integral to this trend, as they allow for faster assembly, reduced on-site construction time, and lower labor costs. These panels are manufactured off-site and can be quickly transported and installed, making them ideal for projects with tight deadlines. The versatility of sandwich panels in prefabricated structures, ranging from residential buildings to industrial applications, has further contributed to their market growth. For instance, in October 2024, Balex Metal offered 110mm and 140mm PIR FROST sandwich panels, expanding its range. These panels, used in food plants, cold stores, and warehouses, meet load-bearing and insulation requirements for walls and ceilings.

Technological Advancements in Insulation

Technological innovations in insulation materials have enhanced the performance and efficiency of sandwich panels. Manufacturers are incorporating advanced insulating cores, such as polyisocyanurate (PIR) and expanded polystyrene (EPS), which provide superior thermal resistance and fire protection. For instance, in 2024, ArcelorMittal Construction expanded its panels portfolio by acquiring Italpannelli SRL in Italy and Italpannelli Iberica in Spain, adding 13 million m² capacity for sandwich panels annually, supporting low-carbon buildings. These advancements are driving the adoption of sandwich panels, particularly in buildings with higher energy performance standards. As the demand for high-performance insulation solutions rises, sandwich panels are becoming a preferred choice for architects and builders who require both functionality and compliance with increasingly stringent energy regulations.

Increasing Focus on Industrial and Commercial Applications

A significant trend in the European sandwich panels market is the growing demand for these panels in industrial and commercial applications. As Europe continues to industrialize, the construction of warehouses, factories, and large commercial buildings has surged. For instance, Tenax Panel's new sandwich panel factory, inaugurated in May 2024, represents a major milestone. With a €13 million investment, it doubles production capacity for export markets, aiming for 1 million m². Sandwich panels are favored in these projects due to their ability to provide fast, cost-effective, and durable solutions. Their lightweight yet robust structure makes them ideal for large-scale commercial and industrial facilities, where speed of construction and energy efficiency are essential. Furthermore, the ability of sandwich panels to provide excellent insulation in harsh climates is particularly important in regions with extreme temperatures, such as northern Europe.

Europe Sandwich Panels Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the Europe sandwich panels market, along with forecasts at the regional and county levels from 2025-2033. The market has been categorized based on type, skin material, technology, application, and end use.

Analysis by Type:

- PUR/PIR

- Mineral Wool

- Expanded Polystyrene (EPS)

- Others

PUR/PIR is an excellent insulator that provides insulation material for sandwich panels with quite high thermal efficiency. They are suitable for usage in energy efficient buildings. In industrial, commercial, and cold storage construction, as the usage of PUR/PIR panels is found in the European market, as their insulation properties and fire resistance value allow them to comply with the stringent environmental standards.

Mineral wool sandwich panels are highly resistant to fire and exhibit excellent sound insulation and thermal performance. Widely used in the construction of industrial and commercial buildings in Europe, these panels are opted for due to their sustainability and safety features. Mineral wool panels form an integral part of any project requiring fire-rated material and are increasingly used in building regulations with higher safety standards.

EPS is one of the lightweight and cheap insulating materials that are applied widely in sandwich panels for most applications in construction. In Europe, EPS panels are very popular in residential and commercial buildings, as they provide good thermal performance at a lower cost. Owing to the simplicity of its application and affordability, EPS continues to dominate in the European market, especially for less demanding insulation needs.

Analysis by Skin Material:

- Continuous Fibre Reinforced Thermoplastics (CFRT)

- Fibreglass Reinforced Panel (FRP)

- Aluminium

- Steel

- Others

CFRT is a high-performance material that has applications for sandwich panel skins with good strength-to-weight ratio, durability, and resistance to environmental factors. Increasingly in Europe, the application of CFRT panels in the automotive and aerospace industries as well as construction industries provide lightweight solutions but high in strength. These factors drive the demand in sustainable construction applications with its recyclability and superior performance.

Fibreglass reinforced panels are highly valued for strength, durability, and resistance to corrosion. FRP is used in the European sandwich panels market for applications in harsh environment, such as chemical plants, warehouses, and cold storage facilities. Since they resist moisture, chemicals, and physical wear, they are ideal for industrial and commercial buildings requiring long-lasting solutions.

Being lighter, resistant to corrosion, and aesthetically pleasing, the popularity of sandwich panel skins of aluminum is much. Aluminium-faced sandwich panels have great demand in European applications of architectural requirements such as façades, roof, and industrial buildings. Thermal and sound insulations provide excellent benefits from modern construction projects through this type, while they add an attractive solution that can last long without significant maintenance.

Steel is one of the most common skin materials in sandwich panels, with advantages such as robustness, and a great deal of inexpensive value. Here, steel faced sandwich panels are employed extensively in industrial, commercial, and agricultural buildings. Indeed, in warehouses, factories, and cold storage, steel imparts structural integrity and protects against elements of the outdoor environment. Its versatility will allow customization in various building designs.

Analysis by Technology:

- Continuous

- Discontinuous

Continuous technology in sandwich panel manufacturing feeds raw materials continuously into the production line to form panels without interruption. In the European market, the continuous sandwich panel provides consistent quality and efficiency in large-scale construction projects. The method is primarily used for high-volume production in industrial and commercial buildings, with uniform insulation and strength.

The batch production of panels is discontinuous technology, whereby individual panels are produced one at a time. In Europe, this method is widely used to produce customized smaller quantities of sandwich panels. Niche applications include cold storage and specialized buildings; discontinuous technology offers flexibility in panel design and material combinations. It allows more control over the quality of the panel and customization.

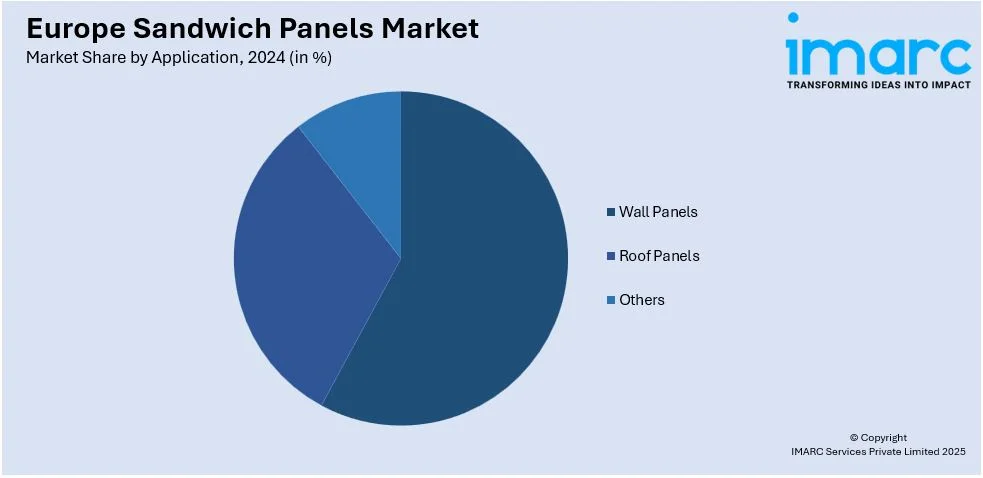

Analysis by Application:

- Wall Panels

- Roof Panels

- Others

The main use of sandwich panels is in the wall panels used primarily for thermal insulation, soundproofing, and structural strength. Wall panels are widely utilized in industrial, commercial, and residential construction throughout the European market. They apply to buildings, including warehouses, factories, and cold storage facilities due to their satisfaction of strict building regulations and sustainability requirements.

Sandwich panel systems feature roof panels that provide excellent thermal insulation and weather resistance. Roofs for industrial or commercial buildings are broadly utilized in Europe because of the durability, energy efficiency, and cost-effectiveness provided by the roof panels. Energy consumption is decreased through the utilization of these panels due to better insulation, especially in warehouses, the energy demand and intensity in cases like distribution centers and facilities in agriculture.

Analysis by End Use:

- Residential

- Commercial

- Industrial

- Institutional and Others

In the residential sector, sandwich panels provide effective thermal insulation and noise reduction, offering energy-efficient solutions for homes. In Europe, these panels are increasingly used in modular and prefab housing, delivering fast construction times and cost savings. Their lightweight nature and ability to meet building regulations make them ideal for low-rise and mid-rise residential buildings.

Commercial buildings in Europe use sandwich panels for their quick installation, energy efficiency, and aesthetic appeal. These panels are commonly used for office buildings, retail stores, and showrooms. Sandwich panels help reduce heating and cooling costs, enhancing sustainability. They also offer flexibility in design, allowing for diverse facades and interior finishes, while meeting stringent building codes and safety standards.

In the industrial sector, sandwich panels are essential for warehouses, factories, and cold storage facilities. These panels provide superior insulation and durability, critical for maintaining temperature control and energy efficiency. In Europe, the demand for industrial sandwich panels continues to grow as businesses seek cost-effective, high-performance solutions that comply with environmental regulations and improve operational efficiency.

Sandwich panels are also widely used in institutional applications, such as schools, hospitals, and sports facilities, where thermal insulation, fire safety, and acoustics are important. In Europe, these panels offer fast construction and long-lasting performance, meeting the rigorous standards for public buildings. Additionally, sandwich panels are used in specialized sectors, including agricultural and temporary structures, providing versatility across various applications.

Country Analysis:

- Germany

- United Kingdom

- France

- Italy

- Russia

- Spain

- Netherlands

- Switzerland

- Poland

- Others

Germany is a significant contributor to the European sandwich panels market. The country boasts a strong industrial base and energy-efficient construction. The commercial, industrial, and residential sectors of the country use sandwich panels extensively. Germany's demand for high-performance panels is fueled by strict building regulations and an emphasis on sustainability, especially in green buildings, warehouses, and cold storage facilities.

The United Kingdom is one of the significant markets for sandwich panels. These panels are widely used in commercial, residential, and industrial building constructions. The UK promotes sustainable building practices. Sandwich panels fit the criteria since they save energy and are installed quickly. Their demand is on the rise because of the regulation and need for green, low-carbon construction solutions.

In France, the sandwich panel is used more extensively in the residential and commercial sectors. The energy-efficient building is a necessary aspect of France, especially within the urban areas. Sandwich panels come into play owing to the significance of sustainable construction for France, thus, this fulfills the standards of the environmental requirements of France. The cost-effectiveness feature of the sandwich panel has enhanced its popularity across industrial facilities and warehouses for major projects.

Italy is a growing market for sandwich panels, especially in the industrial and commercial sectors. The emphasis of the country on sustainable energy-efficient buildings fits well with the properties of sandwich panels. Besides industrial applications, sandwich panels are becoming popular in the construction of residential buildings with quick installation and thermal insulation, which contribute to Italy's green building initiatives.

Due to the enormous size of the country and cold climate, sandwich panels are used both in residential and industrial buildings. Sandwich panels are particularly important for insulated buildings such as warehouses, factories, and cold storage. With the rapid development of the construction industry in Russia, sandwich panels are seen as energy-saving solutions that save on heating costs and meet modern building standards.

Sandwich panels have gained more demand in commercial and residential construction in Spain due to their thermal insulation properties, which are important for the hot climate of the country. Used in office buildings, warehouses, and sports facilities, sandwich panels provide energy savings and fast construction times. Their popularity is further fueled by the emphasis on sustainable, energy-efficient buildings.

The Netherlands uses sandwich panels extensively in both the commercial and industrial sectors, where energy efficiency and sustainability are top priorities. These panels are commonly used for warehouses, cold storage, and manufacturing plants. The country’s commitment to reducing carbon emissions aligns with the growing demand for high-performance sandwich panels, making them an integral part of green construction projects.

Switzerland’s sandwich panels market is driven by the country’s stringent environmental regulations and focus on energy-efficient, sustainable construction. These panels are used in industrial, commercial, and residential buildings, helping to reduce energy consumption and construction time. The Swiss market values high-quality, durable panels that meet stringent building codes and contribute to the country's green building initiatives.

The sandwich panels market in Poland is growing. Particularly, demand from the industrial and commercial segments of the Polish economy has created considerable growth opportunities in the Polish construction industry. Warehouses, factories, and retail buildings are constructed more energy efficiently at lower cost due to increased usage of sandwich panels. Therefore, with increasing modernization of Polish construction industries, sandwich panels become popular because they ensure thermal insulation and durability in buildings and speedy construction.

Competitive Landscape:

The European sandwich panels market is characterized by the presence of both multinational companies and regional players. The market share of key industry leaders is significant, mainly because of their extensive product portfolios, strong distribution networks, and advanced technological capabilities. These companies are focusing on expanding their manufacturing capacities and introducing innovative, energy-efficient solutions to meet growing demand. Additionally, regional manufacturers are increasingly adopting sustainable practices and offering customized solutions to cater to specific construction needs. Intense competition is driving innovation, leading to enhanced product performance and cost efficiency. For instance, in 2024, Ireland's Kingspan launched a joint venture with MV Aceros to produce insulated metal panels and other products for the Paraguayan market, leveraging MV Aceros' local expertise and experience.

The report provides a comprehensive analysis of the competitive landscape in the Europe sandwich panels market with detailed profiles of all major companies, including:

- FischerSIPS

- HEMSEC

- KPS Global

- Green Span Profiles

- Metecno

- ArcelorMittal

- Sintex

- Tata Steel

- Kingspan Group

- Areco

- Rautaruukki Corporation

Latest News and Developments:

- In July 2024, Marcegaglia Steel and Manni Group formed a joint venture in insulated and sectional door panels, combining their expertise in steel processing. This collaboration creates a major player in the Italian market and the second-largest panel producer in Europe, with an estimated combined turnover of around 500 million euros.

Europe Sandwich Panels Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | PUR/PIR, Mineral Wool, Expanded Polystyrene (EPS), Others |

| Skin Materials Covered | Continuous Fibre Reinforced Thermoplastics (CFRT), Fibreglass Reinforced Panel (FRP), Aluminium, Steel, Others |

| Technologies Covered | Continuous, Discontinuous |

| Applications Covered | Wall Panels, Roof Panels, Others |

| End Uses Covered | Residential, Commercial, Industrial, Institutional and Others |

| Countries Covered | Germany, United Kingdom, France, Italy, Russia, Spain, Netherlands, Switzerland, Poland, Others |

| Companies Covered | FischerSIPS, HEMSEC, KPS Global, Green Span Profiles, Metecno, ArcelorMittal, Sintex, Tata Steel, Kingspan Group, Areco, Rautaruukki Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Europe sandwich panels market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the Europe sandwich panels market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Europe sandwich panels industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

Sandwich panels are composite building materials consisting of two strong outer layers (skins) and a lightweight, insulating core. They provide excellent thermal and sound insulation, durability, and structural strength. Sandwich panels are commonly employed in industrial, commercial, and residential construction for energy-efficient, cost-effective solutions for walls, roofs, and ceilings.

The Europe sandwich panels market was valued at USD 4.1 Billion in 2024.

IMARC estimates the Europe sandwich panels market to exhibit a CAGR of 4.47% during 2025-2033.

Key factors driving the Europe sandwich panels market include increasing demand for energy-efficient and sustainable construction, growing industrialization, stringent building regulations, cost-effective and fast installation, and advancements in material technologies. Additionally, the focus on reducing carbon emissions and enhancing building insulation further boosts market growth across various sectors.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)