Conveyor Belt Market Size, Share, Trends and Forecast by Type, End-Use, and Region, 2026-2034

Conveyor Belt Market Size and Share:

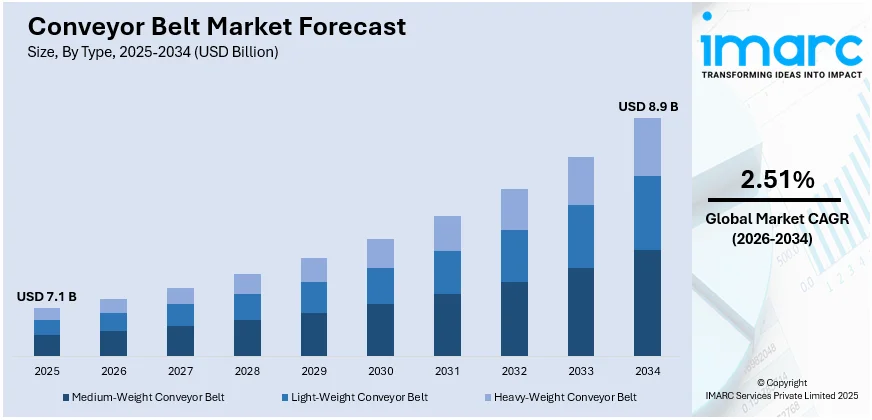

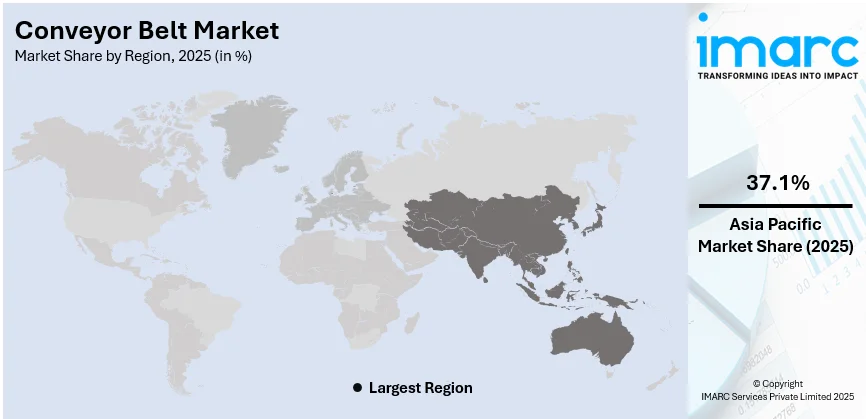

The global conveyor belt market size was valued at USD 7.1 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 8.9 Billion by 2034, exhibiting a CAGR of 2.51% during 2026-2034. Asia-Pacific currently dominates the market, holding a significant market share of over 37.1% in 2025. The rising product demand in baggage handling systems, the increasing product adoption in port operations, the growing product uptake in the pharmaceutical industry worldwide, and the escalating demand for automated storage and retrieval systems are some of the factors offering a positive market outlook.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 7.1 Billion |

| Market Forecast in 2034 | USD 8.9 Billion |

| Market Growth Rate 2026-2034 |

2.51%

|

Several key factors drive the growth and widespread adoption of the conveyor belt market across various industries. The expanding manufacturing and industrial sectors demand efficient material handling solutions, thereby fostering increased use of conveyor systems. For instance, in May 2024, Montech launched a new belt conveyor line designed for cleanrooms certified for ISO air purity classes 4, 5, and 6. These conveyors are tailored for industries such as pharmaceuticals and semiconductors ensuring contamination prevention. Automation trends and the pursuit of operational efficiency further drive the market as businesses seek to streamline processes and reduce labor costs. The rise in ecommerce and logistics operations necessitates robust conveyor solutions to manage high-volume shipments. Technological advancements in belt materials and design and growing infrastructure and construction investments also contribute significantly to the market growth. Moreover, the emphasis on sustainability and energy efficient systems encourages the adoption of modern conveyor belt technologies.

To get more information on this market Request Sample

The United States conveyor belt market is driven by several key factors that boost its expansion and utilization across various sectors. A robust manufacturing and warehousing industry demand efficient material handling solutions increasing the reliance on conveyor systems. For instance, in November 2024, Masaba introduced a new series of self-contained hydraulic radial stacking conveyors, specifically designed for remote job sites. Powered by a 72-horsepower Yanmar diesel unit these conveyors can handle 500 tons per hour and come in standard 36-inch widths and lengths of 80 or 100 feet. The surge in ecommerce and logistics operations necessitates advanced conveyor technologies to manage high-volume shipments swiftly and accurately. The push towards automation and Industry 4.0 enhances operational efficiency and reduces labor costs is further propelling conveyor belt market growth. Technological advancements in belt materials such as increased durability and energy efficiency also play a crucial role. Furthermore, substantial investments in infrastructure and the emphasis on sustainable and ecofriendly solutions contribute significantly to the growth of the United States conveyor belt market.

Conveyor Belt Market Trends:

Increasing infrastructure development worldwide

The growing scope of infrastructure development projects across the globe is creating a positive market outlook. According to reports, global infrastructure investments are projected to reach USD 94 Trillion by 2040, fuelling demand for conveyor belts as industries prioritize efficient material handling and construction operations. The demand for effective delivery of building supplies like aggregates, cement, and concrete increases significantly as infrastructure projects expand. These belts are essential for moving these materials quickly and smoothly throughout building sites, increasing productivity, and lowering labor expenses. Emerging economies are seeing rapid urbanization, which is driving up the construction of public utilities, transit networks, and residential and commercial buildings. The processing of the materials needed for these urban development projects depends heavily on conveyor systems. Building transportation infrastructure, such as highways, railroads, and airports, necessitates the use of large conveyor systems for moving building materials, freight, and passengers. Transportation hub building and operation are accelerated by these belts. Additionally, these belts play a critical role in energy infrastructure projects by making it easier for power plants to carry biomass, coal, and ores. They support the world's electricity demands by helping to generate energy efficiently. Facilities for recycling and garbage management must handle increasing amounts as urban populations grow. Conveyor systems support the automation of trash processing and sorting, in compliance with environmental standards. Additionally, these belts play a crucial role in growing global supply chains by facilitating the effective flow of commodities through ports, warehouses, and distribution hubs to promote global trade.

Rising product demand in the manufacturing industry

The market is stimulated by the growing need for these belts in the manufacturing sector. The global expansion of the industrial industry has made these adaptable material handling systems essential to production procedures. According to India Brand Equity Foundation, manufacturing growth of 11.6% annually and a 9.5% rise in construction sector activity in 2024 is accelerating conveyor belt adoption, supporting efficient operations in expanding industries. These belts play a key role in increasing productivity, decreasing the need for manual labor, and simplifying production processes. They promote just-in-time manufacturing and assembly line production by facilitating the smooth movement of components, raw materials, and completed goods within plants. This increases overall productivity and output quality while quickening the pace of manufacturing. Conveyor system adoption is further fueled by the manufacturing sector's pursuit of operational accuracy and cost-effectiveness. These systems are essential in many production sectors, such as automotive, electronics, and food processing, because they can handle a broad variety of products, from tiny parts to large machines. Conveyor belts help to maintain uniform standards and on-time delivery at a period of increased competition and quality control. The market is growing steadily due to the demand for these belts, which is driven by manufacturers' constant efforts to streamline their manufacturing lines.

Growing number of warehouses and distribution channels

The industry is positively impacted by the growing number of warehouses and distribution channels globally. With the rise in e-commerce and global trade, there is an increasing need for efficient logistics and supply chain management. According to reports, the U.S. has 27,528 general warehousing & storage businesses as of 2023, marking an 8.5% growth from 2022. This expansion fuels conveyor belt adoption, enhancing operational efficiency and meeting rising logistics demands. These belts provide a smooth, automated way to move things, making them essential in these facilities. Warehouses are becoming increasingly complex centers of efficiency, depending on conveyor systems to increase the accuracy and speed of order fulfillment. These systems play a key role in package sorting, picking, and transportation, resulting in quicker delivery times and happier customers. Conveyor belts are also used extensively to load and unload freight in distribution centers, which are growing in number due to the necessity of on-time delivery. Conveyor systems are also essential for moving goods through sizable retail and fulfillment facilities, maximizing the movement from inventory to delivery. Conveyor technology advancements such as automated sorting systems and integrated software, which improve the effectiveness and adaptability of conveyor systems in these growing warehouses and distribution channels, are driving the market growth. As e-commerce and global trade continue to rise, the conveyor belt market demand is set to increase, reaffirming their pivotal role in modern logistics and supply chain operations.

Conveyor Belt Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global conveyor belt market, along with forecasts at the global, regional, and country levels from 2026-2034. The market has been categorized based on type and end-use.

Analysis by Type:

- Medium-Weight Conveyor Belt

- Light-Weight Conveyor Belt

- Heavy-Weight Conveyor Belt

Medium-weight conveyor belt stand as the largest type in 2025, holding around 56.9% of the market. Dominating global market growth, the medium-weight conveyor belt segment plays a crucial role due to its flexibility. Widely used across various industries and applications, this segment is a key driver of market expansion. Its capacity to handle a range of materials and moderately weighted items efficiently is a major advantage. Consequently, medium-weight conveyor belts have become essential in manufacturing, automating material handling, and significantly enhancing production efficiency.

These conveyor belts are also essential in logistics and distribution facilities because they make it easier for products, goods, and packages to move smoothly. The need for dependable and effective conveyor systems in warehouses and distribution centers has increased due to the ongoing growth of e-commerce and the global supply chain, which has further fueled this market's expansion. Additionally, the medium-weight conveyor belt segment offers customization choices that let companies choose belts that meet their unique requirements, whether those demands be material compatibility, speed, or durability. Because of their versatility, medium-weight conveyor belts continue to be the preferred option for businesses looking for economical and effective material handling, thereby securing their place as a key factor in market expansion.

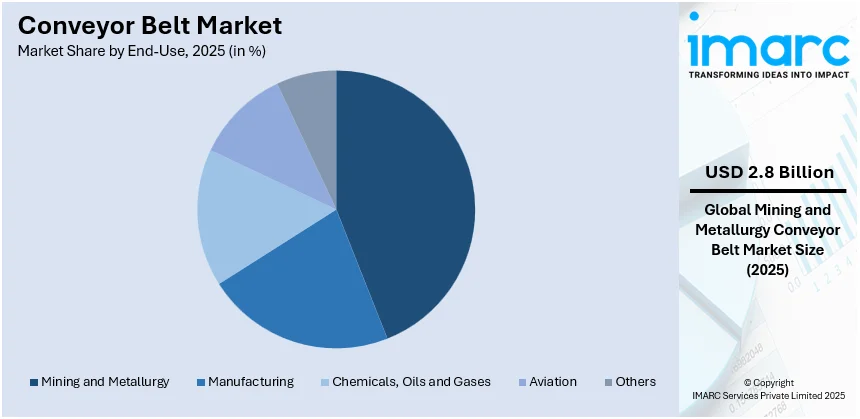

Analysis by End-Use:

Access the comprehensive market breakdown Request Sample

- Mining and Metallurgy

- Manufacturing

- Chemicals, Oils and Gases

- Aviation

- Others

Mining and metallurgy leads the market with around 40.9% of conveyor belt market share in 2025. Mining and metallurgy represent the largest market share globally. Due to several significant variables, this market segment plays a crucial role in propelling its growth. In the mining and metallurgy sector, conveyor belts are vital for the efficient and uninterrupted transport of raw materials, minerals, and ore. These belts guarantee the continuous movement of materials from extraction sites to processing facilities because they are made to endure the severe conditions of mining operations. By eliminating the need for heavy equipment and physical labor, they also improve safety in mining operations by lowering the possibility of mishaps and injuries. They help to raise operational safety standards by being dependable while transporting heavy loads over long distances.

Furthermore, the expansion of infrastructure, urbanization, and technological improvements are facilitating the demand for metals and minerals worldwide. Conveyor belts are essential for fulfilling this demand because they make it easier to move mined resources, allowing for prompt manufacturing and delivery to satisfy market demands. Furthermore, advancements in conveyor belt technology, such as increased robustness, automation, and monitoring capabilities, are observed in the mining and metallurgy industry. These developments increase operational effectiveness and decrease downtime, which encourages the industry to embrace conveyor systems even more.

Regional Analysis:

To get more information on the regional analysis of this market Request Sample

- Asia Pacific

- Europe

- North America

- Middle East and Africa

- Latin America

In 2025, Asia-Pacific accounted for the largest market share of over 37.1%. The Asia Pacific region emerges as a major driver propelling the growth of the conveyor belt market. This market's notable growth in the region is attributed to several important factors. Conveyor belt demand is fueled by the need for effective material handling solutions brought on by rapid industrialization and urbanization. The region's expanding production demands are supported by these belts, which are essential to a variety of businesses, including mining and manufacturing. Furthermore, the rising e-commerce industry has led to a substantial increase in distribution centers and warehouses. Conveyor belts are essential for automating the movement and sorting of items, which simplifies supply chain and logistics processes that are necessary for on-time delivery.

Furthermore, conveyor belts are essential to the effective movement of ores and raw materials in the region's growing mining and construction industries. The demand for conveyor systems is further fueled by the ongoing expansion of this industry. Additionally, producers of conveyor belts are spending money on new technologies that will increase the effectiveness and versatility of conveyor systems. These developments support market expansion by meeting the various demands of the region's industries.

Key Regional Takeaways:

North America Conveyor Belt Market Analysis

The North American conveyor belt market is witnessing substantial growth driven by dynamic industrial expansion and advancements in automation technologies. Key sectors such as manufacturing, automotive, food processing and logistics are significantly increasing their adoption of conveyor systems to enhance material handling efficiency and streamline operations. The surge in ecommerce and the consequent demand for efficient warehouse and distribution center operations further propel the market as businesses seek to optimize supply chain logistics. Technological innovations including the integration of Internet of Things (IoT) and smart automation are enhancing the performance and reliability of conveyor belts making them essential components in modern production and distribution environments. Additionally, the emphasis on sustainability is fostering the development and adoption of energy efficient and recyclable conveyor belt solutions aligning with stringent environmental regulations and corporate sustainability goals. Investments in infrastructure modernization and the upgrading of existing facilities across the United States and Canada also contribute to market growth. Collectively, these factors establish North America as a pivotal region for the expansion and advancement of the conveyor belt market.

United States Conveyor Belt Market Analysis

In 2025, United States accounted for a share of 83.00% of the North America market. The adoption of conveyor belts is expanding due to the surging urbanization that has accelerated aviation sector development. As airports grow to accommodate increasing passenger volumes efficient baggage handling systems are essential. For instance, the growing number of U.S. airports, reaching 1,251 in 2023, is driving increased adoption of conveyor belts streamlining baggage handling and enhancing operational efficiency. Conveyor belts are being integrated into advanced logistics networks to streamline operations in terminals and cargo areas. This infrastructure evolution supports faster and more organized transportation of goods and passengers' belongings aligning with the rising demand for automation. Additionally, the expansion of regional logistics hubs necessitates robust and efficient material handling solutions further boosting conveyor belt utilization. Advanced materials and designs enhance durability and minimize maintenance making them ideal for high-traffic environments. Enhanced reliability and seamless integration into automated systems make conveyor belts indispensable in supporting aviation infrastructure growth.

Europe Conveyor Belt Market Analysis

The adoption of conveyor belts continues to expand mainly driven by rapid industrialization. Industries ranging from food processing to pharmaceuticals are investing in efficient material transport systems to meet growing production demands. According to EU, the EU's production of 271.6 Million tonnes of cereals in 2023 highlights the growing food processing demand driving increased adoption of conveyor belts for efficient handling and processing. Conveyor belts enhance workflow by automating repetitive tasks, reducing manual labour and ensuring consistent quality. The transition to ecofriendly manufacturing practices has also spurred interest in energy efficient conveyor belt technologies. Customizable designs support diverse industrial needs from lightweight belts for delicate items to heavy-duty solutions for bulk materials. This adaptability ensures smooth operations in high-demand sectors while supporting compliance with strict environmental and operational standards. Technological advancements have further cemented conveyor belts as integral to industrial progress.

Latin America Conveyor Belt Market Analysis

The growing adoption of conveyor belts is closely linked to advancements in the mining sector. According to J.P. Morgan, Latin America's robust mining sector is contributing 40% of global copper production boosts conveyor belt adoption due to heightened demand in Chile, Peru and Mexico's operations. Enhanced efficiency and scalability in mining processes drive growth. Efficient transportation of ores and minerals from excavation sites to processing units requires durable and high-capacity conveyor systems. These belts minimize handling time and operational costs while improving safety in challenging terrains. Enhanced designs ensure resilience against extreme conditions including abrasive materials and heavy loads making them indispensable for modern mining operations. Conveyor belts also support eco-conscious practices by reducing emissions associated with alternative transport methods. As mineral extraction becomes more advanced conveyor belt systems are increasingly integrated into mining logistics.

Middle East and Africa Conveyor Belt Market Analysis

The rise in conveyor belt adoption aligns with expanding real estate activities. Rapid construction projects including residential and commercial developments demand efficient systems for material handling. According to reports, Saudi Arabia's booming construction sector with over 5,200 projects worth USD 819 Billion is driving increased adoption of conveyor belts for efficient material handling and project execution. Conveyor belts are essential in transporting construction materials such as cement, aggregates and steel streamlining workflows and minimizing delays. Their ability to function in harsh conditions ensures uninterrupted operations on large-scale sites. Advanced designs also enhance the speed and precision of material transport, enabling faster project completion. The integration of automated systems into construction workflows highlights conveyor belts as a critical component in modernizing the sector.

Competitive Landscape:

The conveyor belt market is characterized by intense competition driven by innovation, customization, and regional market demands. Key players focus on developing advanced technologies, such as energy efficient belts, lightweight materials, and improved durability to meet industry specific requirements. Automation and smart technologies are increasingly integrated to enhance operational efficiency reflecting market trends toward digitization. Regional manufacturers often compete on cost effectiveness and rapid delivery while global companies emphasize quality, innovation, and after-sales services. Sustainability is becoming a critical factor with competitors offering ecofriendly products to meet regulatory and customer demands. Strategic partnerships and expansions are common as companies aim to strengthen their market presence, enhance distribution networks and cater to growing industries like ecommerce, mining, and construction. For instance, in February 2024, Fenner Dunlop and International Conveyor and Rubber (ICR) announced their partnership to enhance conveyor belt services for underground coal mining. This alliance combines Fenner Dunlop’s premium products with ICR’s extensive expertise in installation and maintenance ensuring improved service quality and operational efficiency for mining operations across the Eastern US.

The report provides a comprehensive analysis of the competitive landscape in the conveyor belt market with detailed profiles of all major companies, including:

- Bando Chemical Industries, Ltd.

- Fenner

- Intralox

- Volta Belting Technology Ltd

- Fives

Latest News and Developments:

- September 2025: Shanghai Puteken Transmission System Co., Ltd., a reputable name in transmission and conveyor solutions, unveiled its high-performance silicone conveyor belt, created to address the changing demands of industries globally. Recognized for its quality and innovations, the company established standards by providing dependable and long-lasting conveyor solutions for various applications.

- September 2025: Purnia was set to officially open its new airport in India, with Prime Minister Narendra Modi presiding, marking Bihar’s fourth active civilian airport. The temporary terminal structure at Purnia was built on 3,000 square meters with an estimated expense of INR 34 Crore. The one-level building featured six check-in desks, a single conveyor belt, and two hand luggage machines.

- July 2025: The Pune Airport introduced its ‘meet and greet’ and porter services, inspired by the classic porter (coolie) service found at Indian railway stations. These services aimed to help travelers, particularly elderly individuals, women, people with disabilities, and those with heavy luggage, by offering assistance from the airport entrance to security check-in for departing passengers and from the conveyor belt to taxi stands for arrivals in Pune.

- April 2025: NTPC's Pakri Barwadih coal mining initiative launched a 21-kilometre conveyor belt system to carry coal to Hazaribag railway station. The system included high-capacity steel cord belts with widths between 1,800mm and 2,200mm, engineered for exceptional tensile strength and dependability.

- January 2025: Wuxi Boton of China and iron ore producer Roy Hill finalized a new Conveyor Belt and Services Partnership Agreement in Wuxi, enhancing their cooperation. This collaboration not only sustained their efforts in conveyor belt provision and associated services but also brought forth groundbreaking tools, such as smart monitoring devices and digital management systems. They entered into an alliance to promote a Total Cost of Ownership (TCO) innovative partnership model.

Conveyor Belt Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Medium-Weight Conveyor Belt, Light-Weight Conveyor Belt, Heavy-Weight Conveyor Belt |

| End-Uses Covered | Mining and Metallurgy, Manufacturing, Chemicals, Oils and Gases, Aviation, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Companies Covered | Bando Chemical Industries, Ltd., Fenner, Intralox, Volta Belting Technology Ltd., Fives, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the conveyor belt market from 2020-2034.

- The conveyor belt market research report provides the latest information on the market drivers, challenges, and opportunities in the global market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the conveyor belt industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

A conveyor belt is a continuous loop of material that moves over rollers or a flat surface to transport goods and materials efficiently across various industries, including manufacturing, mining, logistics, and construction.

The global conveyor belt market was valued at USD 7.1 Billion in 2025.

IMARC estimates the global conveyor belt market to exhibit a CAGR of 2.51% during 2026-2034.

The market is driven by increasing demand for efficient material handling, automation trends, growing e-commerce and logistics operations, rising infrastructure development, and advancements in belt technologies focusing on sustainability and energy efficiency.

In 2025, medium-weight conveyor belts represented the largest segment by type, driven by their versatility and widespread adoption across industries.

Mining and metallurgy lead the market by end-use owing to the heavy reliance on conveyor belts for transporting materials in harsh operational environments.

On a regional level, the market has been classified into North America, Asia Pacific, Europe, Latin America, and Middle East and Africa, wherein Asia Pacific currently dominates the global market.

Some of the major players in the global conveyor belt market include Bando Chemical Industries, Ltd., Fenner, Intralox, Volta Belting Technology Ltd., Fives, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)