China Ceramic Ball Bearing Market Size, Share, Trends and Forecast by Raw Material, Product Type, Application, and Region, 2026-2034

China Ceramic Ball Bearing Market Size and Share:

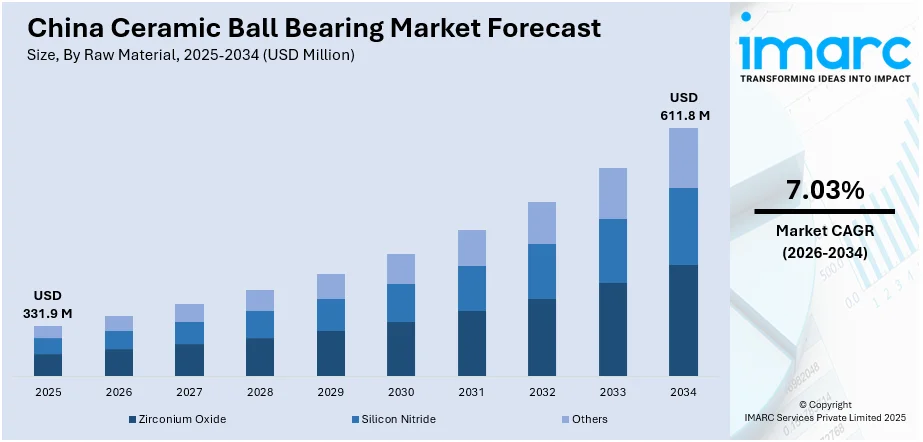

The China ceramic ball bearing market size was valued at USD 331.9 Million in 2025. Looking forward, IMARC Group estimates the market to reach USD 611.8 Million by 2034, exhibiting a CAGR of 7.03% from 2026-2034. The increasing awareness about the superior properties of these bearings, rapid industrialization in the country, significant growth in vehicle production, ongoing technological advancements, and rising demand for energy efficiency, are some of the factors boosting the China ceramic ball bearing market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 331.9 Million |

|

Market Forecast in 2034

|

USD 611.8 Million |

| Market Growth Rate 2026-2034 | 7.03% |

Ceramic ball bearings are famous for their outstanding physical properties, such as high hardness, low density, and superior corrosion resistance. These characteristics allow them to perform well under harsh conditions, like high temperatures, absence of lubrication, and corrosive environments, which makes them extremely sought after in many industries. In 2024, China's market demand for high-end precision bearings, including ceramic ball bearings, has been increasing continuously. The size of the market for the industry continues to grow, fueled by industries like automobiles, aerospace, and machinery. This is a reflection of the growing dependence on sophisticated bearing technologies to address the changing requirements of these industries. The superior physical characteristics of ceramic ball bearings are responsible for their increasing use in mission-critical applications. These qualities not only enhance the efficiency and lifespan of equipment but also promote energy efficiency as well as low maintenance.

To get more information on this market Request Sample

China's accelerated industrial growth has played a major role in boosting the China ceramic ball bearing market demand. In 2024, the value-added industrial output of the country rose by 5.8% year on year, up from the 4.6% recorded in 2023. The strong performance of industry has boosted the need for sophisticated machinery and components, such as ceramic ball bearings, that are imperative to maintain smooth operations and improved productivity levels in different industries. The manufacturing sector, more specifically, has been the primary vehicle for this growth. In November 2024, the value-added production of the manufacturing sector rose by 5.4% compared to the same period last year. This growth is indicative of the sector's resilience and its ability to serve both domestic and overseas requirements. When manufacturing activity grows stronger, the demand for high-performing components is further driving the China ceramic ball bearing market growth.

China Ceramic Ball Bearing Market Trends:

Significant Growth in the Automotive Industry

The rapid expansion of the automotive industry has significantly contributed to the growth of the China ceramic ball bearing market share. In 2024, the country achieved a new milestone, with both production and sales exceeding 31 million units. Specifically, total auto output reached 31.282 million units, marking a 3.7% increase compared to 2023, while sales rose by 4.5% year on year, totaling 31.436 million units. This strong growth is also reflected in the results from the first nine months of 2024, with auto production reaching about 21.47 million units, marking a 1.9% year-over-year increase, while sales hit 21.57 million units, up by 2.4% compared to the same period last year. The automotive sector's expansion has spurred demand for high-performance components, including ceramic ball bearings, which are essential for ensuring smooth operations and enhanced productivity in automotive applications. These bearings are utilized in various automotive systems, such as engines, transmissions, and suspension systems, due to their superior performance characteristics.

Rapid Technological Advancements

Technological advancements have significantly propelled the growth of the ceramic ball bearing market in China. Innovations in materials science and manufacturing processes have enhanced the performance and applicability of ceramic ball bearings across various industries. The country's dedication to innovation is clear through its strategic efforts focused on improving manufacturing capabilities and promoting high-quality development. In 2024, the State Council Information Office of China emphasized the importance of technological innovation in driving economic growth. The briefing highlighted that pursuing high-quality development is essential for building a modern economic system. This focus on innovation has led to increased investments in research and development, particularly advancements in manufacturing technologies, such as precision engineering and novel manufacturing processes. These developments have led to ceramic ball bearings with enhanced performance, including higher load capacity, reduced friction, and increased speed capabilities.

Growing Demand for Energy Efficiency

China’s push for enhanced energy efficiency and carbon reduction is a crucial factor driving the demand for ceramic ball bearings. As part of its environmental strategy, the Chinese government set ambitious goals to reduce energy consumption and promote sustainable technologies. In May 2024, the government introduced new initiatives to boost energy efficiency, setting a goal to reduce energy consumption per unit of industrial output by around 3.5% in 2024. Additionally, it aims to raise the share of non-fossil energy consumption to 18.9% in 2024 and 20% by 2025. These efforts are designed to reduce carbon emissions by 130 million tons over the next two years, further emphasizing energy conservation across industries. In line with this, industries are seeking components that can reduce energy consumption while maintaining high performance. Ceramic ball bearings, known for their low friction and high durability, are an ideal solution in this context. Their ability to minimize energy loss during operation makes them highly valued in sectors such as automotive, manufacturing, and machinery, where energy efficiency is paramount.

China Ceramic Ball Bearing Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the China ceramic ball bearing market, along with forecasts at the country and regional levels from 2026-2034. The market has been categorized based on raw material, product type, and application.

Analysis by Raw Material:

- Zirconium Oxide

- Silicon Nitride

- Others

The ceramic ball bearing market is dominated by silicon nitride, a material with superior properties in comparison with other alternatives. Notable are its properties of excellent hardness, great resistance to high temperature, and very low thermal expansion, especially for applications in which durability and precision are critical. The resistance to wear, corrosion, and fatigue greatly enhances the life of bearings in harsh applications. These properties make silicon nitride an important material in the aerospace, automotive, and other high-tech industries, where there are extreme demands for high-speed and extreme working conditions. The capability of the material to permit higher speeds and extreme conditions gives silicon nitride an edge in sectors requiring higher tolerances of precision and reliability. This leads to its widespread application in high-speed electric motors, turbochargers, and medical devices.

Analysis by Product Type:

- Hybrid Ceramic Ball Bearings

- Full Ceramic Ball Bearings

As per the latest China ceramic ball bearing market outlook, hybrid ceramic ball bearings consist of ceramic balls set against steel races and dominate the market because of their improved functional characteristics. They combine the long life and corrosion resistance of ceramics with the strength and load-bearing capacity of steel. A dramatic reduction in friction takes place with the use of hybrid ceramics because these ball bearings are constructed with ceramic balls which, along with lowering heat generation, leads to a higher operating efficiency than all-steel bearings. In addition, the hybrid ceramic bearings can run at increased speeds and temperatures, ideal for high-performing applications in the automotive, aerospace, and the manufacturing industries. Further, they provide reduced maintenance, lower breakdown, and longer life, leading to cheaper downtime costs in the long run. The demand for increased efficiency, precision, and reliability are factors enhancing the growth of hybrid ceramic ball bearings in various industries.

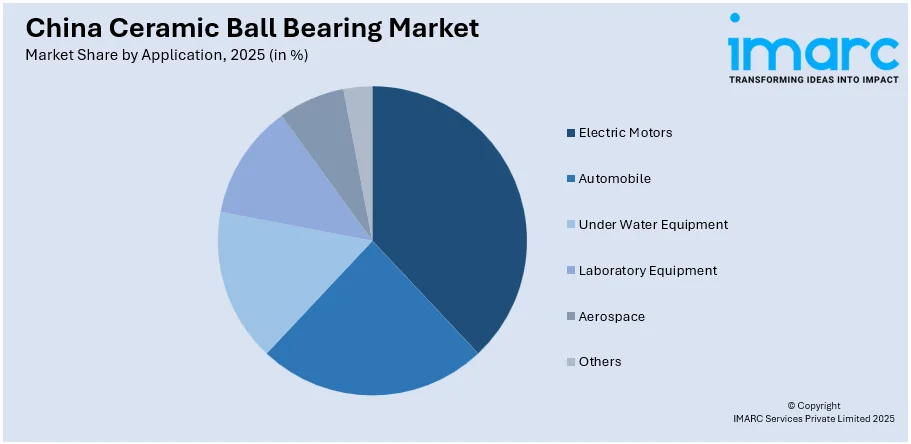

Analysis by Application:

Access the comprehensive market breakdown Request Sample

- Electric Motors

- Automobile

- Under Water Equipment

- Laboratory Equipment

- Aerospace

- Others

As per the recent China ceramic ball bearing market analysis, the most prominent segment in the application of these bearings is electric motors, as they are extensively dispersed in all the manufacturing sectors. From home appliances to industrial manufacturing, everything employs electric motors, and when electric motors spin at high speeds and carry heavy loads, this requires application of bearings with a long fatigue life. Owing to their high wear resistance, low friction, and ability to support high temperatures, ceramic ball bearings are increasingly popular in electric motor applications. These assist not just in the friction reduction but also enhance energy efficiency in electric motors as well as overall performance and lifespan. With the worldwide thrust towards energy-saving technologies, and the growing use of electric cars and renewable energy systems, the demand for ceramic ball bearings in electric motor applications is further being driven. As the market for electric motors is growing, particularly in the automobile and renewable energy industries, the demand for high-performance, long-lasting bearings will keep growing.

Regional Analysis:

- Guangdong

- Jiangsu

- Shandong

- Zhejiang

- Henan

- Others

Guangdong is one of China's most industrialized provinces and has the largest market share in ceramic ball bearings. It boasts a strong manufacturing sector, with key sectors encompassing electronics, automobiles, machinery, and aerospace industries. Guangdong houses a vast array of companies using high-performance components such as ceramic ball bearings to maintain precision, durability, and efficiency in the performance of their products. Proper and well-developed infrastructure with its skilled labour as well as with proximity to world's supply chain hubs attracts significant demand of premium bearings within its region. Plus, innovations have been sought towards energy saving or high performance at Guangdong where the main industrial sectors comprise electricity motors, robot manufacturing as well as vehicle producing industries thus high demand on its ceramic ball bearing.

Competitive Landscape:

Prominent ceramic ball bearing manufacturers are adopting various strategies to foster competitiveness and propel the market growth. Many of the companies are investing heavily in R&D to innovate and rejuvenate their product performance. Through improved materials like silicon nitride for ceramic bearings and hybrid designs combining ceramic balls with steel races, these manufacturers cater to dynamically increasing demands for high-performance and energy-efficient bearings. They will concentrate on widening their product offerings to serve all the industries like automotive, aerospace, robotics, and renewable energy. Other challenges that the manufacturers are still able to overcome include the growing production capacities and developing strategic alliances with the key industries. This is the step for these companies to enter some new markets and provide customized solutions for the customers. In addition to this, leading players are focused on dynamic expansions in their global footprints through effective distribution networks and entry into the emerging markets with industrialization and technology development on the rise.

The report provides a comprehensive analysis of the competitive landscape in the China ceramic ball bearing market with detailed profiles of all major companies, including:

- Honeywell

- Axens

- Saint-Gobain

- TSUBAKI NAKASHIMA

- Amatsuji Steel Ball Mfg. Co., Ltd.

- Tosoh

- Nikkato

- CENOTEC Co., Ltd.

- ZHIMO

- Netzsch

- Coorstek

Latest News and Developments:

- In July 2023, SKF and Sinoma Nitride entered into a joint venture (JV) agreement to strengthen their cooperation in the development of hybrid ceramic ball bearings. Under this agreement, SKF will own a 30% share and will manufacture nitride rolling elements.

- In December 2024, the Swedish bearing maker SKF Group made intentions to increase its investments in China. The company's goal is to localize every step of its value chain, including R&D, sourcing, and production. SKF's collaboration with Nio, a top Chinese EV producer, to provide ceramic ball bearings specifically designed for electric vehicles is a key component of this plan.

- In December 2024, Leading bearing industry pioneer HSN Group announced that it would be attending the 2024 China International Bearing Industry Exhibition. The business demonstrated cutting-edge bearing technology and customized bearing solutions made to satisfy the changing needs of various industries, including metal, industrial machinery, automobiles, and agricultural equipment.

- In September 2023, researchers in China made significant progress in the grinding processing technology of bearing ceramic balls. The new methods developed aim to enhance the surface finish and dimensional accuracy of ceramic balls, leading to improved performance and longevity of ceramic ball bearings.

China Ceramic Ball Bearing Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Raw Materials Covered | Zirconium Oxide, Silicon Nitride, Others |

| Product Types Covered | Hybrid Ceramic Ball Bearings, Full Ceramic Ball Bearings |

| Applications Covered | Electric Motors, Automobile, Under Water Equipment, Laboratory Equipment, Aerospace, Others |

| Regions Covered | Guangdong, Jiangsu, Shandong, Zhejiang, Henan, Others |

| Companies Covered | Honeywell, Axens, Saint-Gobain, TSUBAKI NAKASHIMA, Amatsuji Steel Ball Mfg. Co., Ltd., Tosoh, Nikkato, CENOTEC Co., Ltd., ZHIMO, Netzsch, Coorstek, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the China ceramic ball bearing market from 2020-2034.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the China ceramic ball bearing market.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the China ceramic ball bearing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The ceramic ball bearing market in China was valued at USD 331.9 Million in 2025.

The increasing awareness about the superior properties of these bearings, rapid industrialization in the country, significant growth in vehicle production, ongoing technological advancements, and rising demand for energy efficiency, are some of the factors boosting the China ceramic ball bearing market growth.

The China ceramic ball bearing market is projected to exhibit a CAGR of 7.03% during 2026-2034, reaching a value of USD 611.8 Million by 2034.

Silicon nitride holds the majority of the raw materials market share due to its superior properties compared to other materials.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)