Brazil Metal Fabrication Equipment Market Report by Product Type (Automatic, Semi - Automatic, Manual), Equipment Type (Cutting, Machining, Forming, Welding, and Others), End Use Industry (Oil and Gas, Manufacturing, Power and Utilities, Construction, and Others), and Region 2026-2034

Market Overview:

Brazil metal fabrication equipment market size reached USD 1.3 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 1.7 Billion by 2034, exhibiting a growth rate (CAGR) of 2.86% during 2026-2034. The rising economic stability in the country, increasing investment in infrastructure development, rapid technological advancements, emergence of small and medium-sized enterprises (SMEs), growing focus on customization, and the rising aerospace and defense sectors represent some of the key factors driving the market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 1.3 Billion |

|

Market Forecast in 2034

|

USD 1.7 Billion |

| Market Growth Rate 2026-2034 | 2.86% |

Metal fabrication equipment refers to specialized machinery and tools employed for converting raw metals into finished or semi-finished structures. It encompasses a variety of equipment, including welding machines, laser cutting systems, press brakes, and shearing machines. Metal fabrication equipment is manufactured using stainless steel and aluminum for long-lasting durability. It finds application in automotive manufacturing, construction, aerospace, shipbuilding, energy production, heavy machinery, and consumer goods. Metal fabrication equipment offers numerous benefits, such as increased efficiency, precision, and speed in manufacturing processes. It also provides enhanced safety features, customization capabilities, cost-effectiveness, and various materials and techniques adaptability. Furthermore, metal fabrication equipment is known for its reliability, operational simplicity, low maintenance requirements, and technological advancements, such as computer numerical control (CNC) capabilities.

Brazil Metal Fabrication Equipment Market Trends:

Economic Growth and Industrial Advancements

The rising economic stability and pro-industrial policies in Brazil are among the major factors stimulating the market growth. In line with this, the increasing government investment in infrastructure development and modernization of industrial sectors, facilitating industrial equipment adoption, is positively influencing the market growth. Besides this, the growing equipment utilization owing to the widespread adoption of complex designs and lightweight materials in the automotive sector is strengthening the market growth. Additionally, the rising aerospace and defense sectors in Brazil, requiring high-quality metal components that meet stringent quality and safety standards, are favoring the market growth. Furthermore, the heightened application of metal fabrication equipment in the renewable energy sector, due to the adoption of complex metal structures, is driving the market growth. Along with this, rapid advancements such as the integration of the Internet of Things (IoT) technologies and automation to enhance the capabilities of existing equipment are bolstering the market growth. In line with this, the widespread adoption of computerized numerical control (CNC) technology in modern metal fabrication, allowing for greater accuracy and speed in manufacturing processes, is providing an impetus to the market growth. This includes advanced processes like laser cutting fabrication, which improve precision and reduce material loss in production. Apart from this, the growing equipment demand in the country due to the rising development of export-oriented manufacturing units is providing a thrust to the market growth. In confluence with this, the emergence of small and medium-sized enterprises (SMEs) in the manufacturing sector, prompting the demand for versatile and cost-effective industrial equipment such as industrial mixers, is supporting the market growth. Besides this, the increasing focus on domestic manufacturing, encouraging Brazilian companies to invest in state-of-the-art metal fabrication equipment, is anticipated to drive the market growth.

Intelligent Fabrication in Brazil's Metals Industry

The Brazilian market is undergoing significant changes with the increasing adoption of of smart fabrication technologies. IoT, automation, and AI usage are making factories gather data in real time, which enables predictive maintenance and maximizes overall efficiency. Intelligent machines capable of communicating and cooperating with each other are making production smoother and faster, resulting in quicker, more flexible manufacturing operations. For high-precision industries, such as aerospace or the auto industry, they offer improved quality control and faster turnaround. As Brazil continues to improve its manufacturing capacity, intelligent fabrication is increasingly becoming an important factor in increasing productivity and guaranteeing competitive edges on the international level.

Additive Manufacturing in the Metal Industry in Brazil

Additive manufacturing, also known as 3D printing, is gaining popularity in Brazil's metal fabrication sector. It enables the production of complex and highly customized metal parts with a high level of precision. Since it utilizes only the necessary amount of material, it saves on waste and reduces material costs, making it a preferred choice for various industries. The automobile, aviation, and medical industries, which typically require special, precision-crafted parts, are the biggest beneficiaries of 3D printing. The process simplifies production workflows by enabling quick prototyping, producing short runs, and allowing for the manufacture of complex geometries that would be too expensive or challenging with conventional manufacturing techniques. Additive manufacturing also has the flexibility of quickly responding to shifting demands. As innovation in this sector continues, it is likely to further revolutionize the metal production environment in Brazil, opening new doors for efficiency, creativity, and competitiveness in both domestic and international markets.

Brazil Metal Fabrication Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on product type, equipment type, and end use industry.

Product Type Insights:

- Automatic

- Semi - Automatic

- Manual

The report has provided a detailed breakup and analysis of the market based on the product type. This includes automatic, semi - automatic, and manual.

Equipment Type Insights:

- Cutting

- Machining

- Forming

- Welding

- Others

A detailed breakup and analysis of the market based on the equipment type have also been provided in the report. This includes cutting, machining, forming, welding, and others.

End Use Industry Insights:

- Oil and Gas

- Manufacturing

- Power and Utilities

- Construction

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes oil and gas, manufacturing, power and utilities, construction, and others.

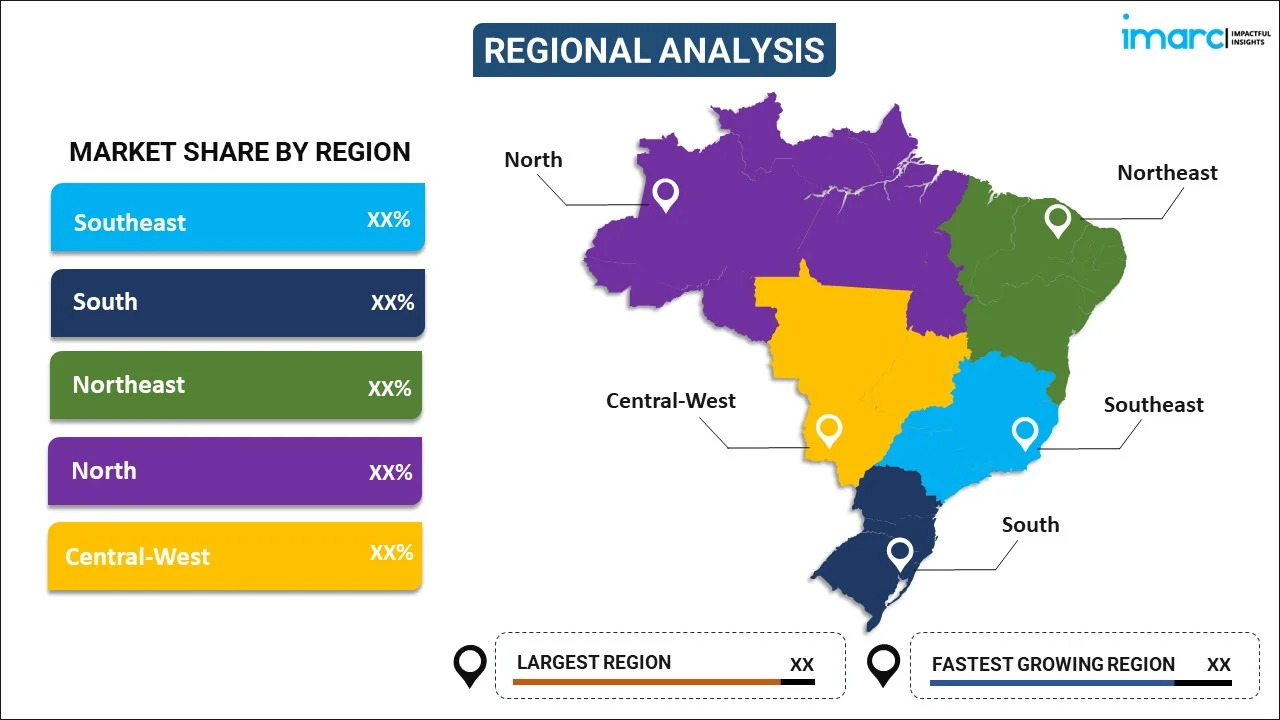

Regional Insights:

- Southeast

- South

- Northeast

- North

- Central-West

The report has also provided a comprehensive analysis of all the major regional markets, which include Southeast, South, Northeast, North, and Central-West.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Brazil Metal Fabrication Equipment Market Recent News:

- May 2025: MetalWorm partnered with Instituto Federal do Maranhão (IFMA) in Brazil to enhance academic and research activities in Wire Arc Additive Manufacturing (WAAM). This collaboration introduced advanced WAAM equipment to support alloy development, training, and research, driving innovation in Brazil's metal fabrication equipment market.

- April 2025: General Motors launched its GM Tooling service business in Brazil, offering a comprehensive range of metal fabrication solutions. The service, focused on industries like automotive and metalworking, boosts Brazil's metal fabrication equipment market by providing advanced tooling, machining, and manufacturing services, driving innovation.

- December 2024: Petrobras launched LABi3D at its CENPES research center in Rio de Janeiro, advancing additive manufacturing in the oil and gas sector. This facility, equipped with cutting-edge technologies, boosts Brazil’s metal fabrication equipment market by enhancing production efficiency and fostering innovation in industrial processes.

Brazil Metal Fabrication Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Product Types Covered | Automatic, Semi - Automatic, Manual |

| Equipment Types Covered | Cutting, Machining, Forming, Welding, Others |

| End Use Industries Covered | Oil and Gas, Manufacturing, Power and Utilities, Construction, Others |

| Regions Covered | Southeast, South, Northeast, North, Central-West |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Brazil metal fabrication equipment market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Brazil metal fabrication equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Brazil metal fabrication equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The Brazil metal fabrication equipment market is projected to grow at a CAGR of 2.86% during 2026-2034.

The growth of Brazil's metal fabrication equipment market is fueled by rising demand in sectors like automotive, construction, and aerospace. Key drivers include advancements in automation, additive manufacturing, and the push for higher efficiency, precision, and cost-effectiveness in production processes.

The COVID-19 pandemic caused disruptions in Brazil's metal fabrication sector, leading to supply chain delays and higher production costs. However, the crisis also accelerated the adoption of automation and digital technologies, as businesses focused on enhancing operational efficiency and reducing reliance on manual labor.

Based on the product type, the Brazil metal fabrication equipment market has been segmented into automatic, semi - automatic, and manual.

Based on the equipment type, the Brazil metal fabrication equipment market has been segmented into cutting, machining, forming, welding, and others.

Based on the end use industry, the Brazil metal fabrication equipment market has been segmented into oil and gas, manufacturing, power and utilities, construction, and others.

On a regional level, the Brazil metal fabrication equipment market has been segmented into Southeast, South, Northeast, North, and Central-West.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)