Axial Flow Pump Market Report by Type (Miniwatt, High Power), Application (Domestic Water and Wastewater, Petroleum, Chemical, Food and Beverage, and Others), and Region 2025-2033

Market Overview:

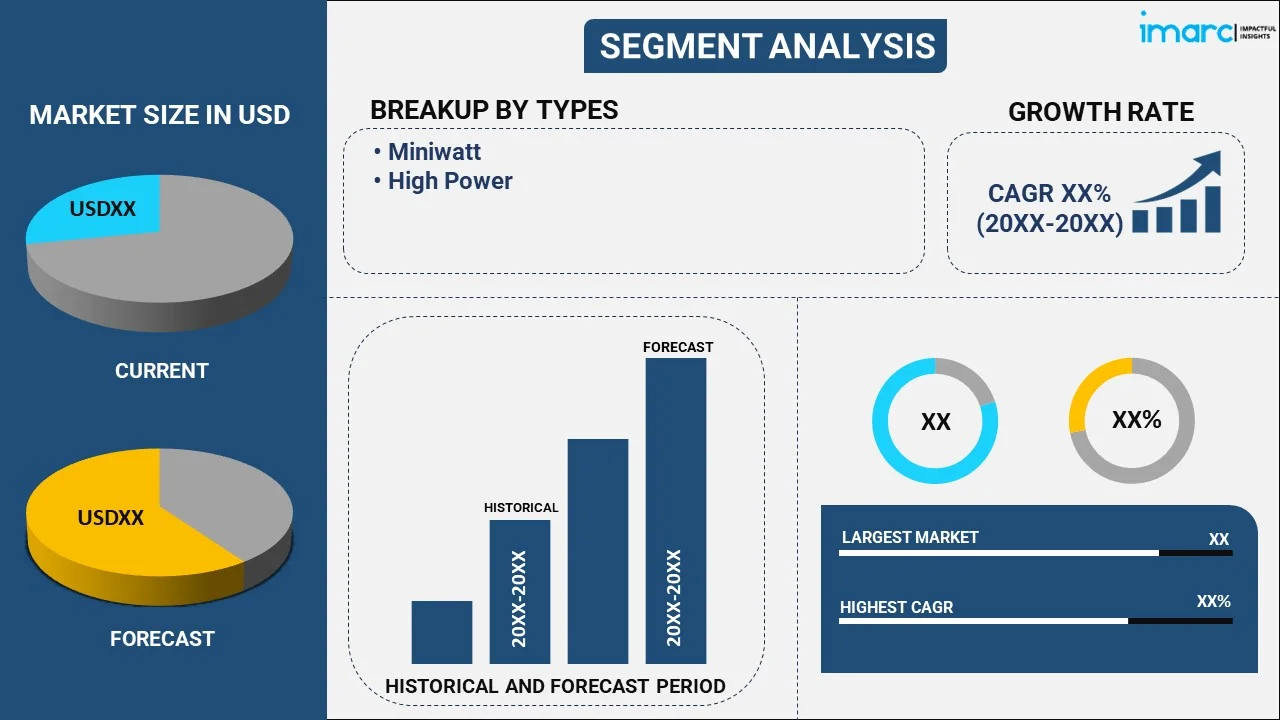

The global axial flow pump market size reached USD 4.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 7.0 Billion by 2033, exhibiting a growth rate (CAGR) of 5.04% during 2025-2033. At present, Asia Pacific region holds the largest market share driven by rapid industrialization, urbanization, and infrastructure development.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 4.4 Billion |

| Market Forecast in 2033 | USD 7.0 Billion |

| Market Growth Rate (2025-2033) | 5.04% |

Axial flow pump is a positive displacement pump used for circulating water in power and chemical manufacturing plants. The pump is usually manufactured using materials, such as cast iron, plastic, aluminum, brass, bronze and ceramics and consists of a horizontal shaft, suction and discharge lines and concrete inlet and outlet canals. It increases the pressure causing an axial acceleration of liquid within the blades. The pumps are widely used for irrigation, sewage treatment, cooling water pumps and operating drainage systems. In comparison to the traditionally used centrifugal pumps, axial flow pumps offer improved flow rate in low-pressure applications with low aerodynamic losses. As a result, it finds extensive applications across various industries, including oil and gas, wastewater treatment, chemical and food and beverage.

Rapid industrialization across the globe is one of the key factors driving the growth of the market. Furthermore, increasing demand for effective wastewater treatment solutions is providing a thrust to the market growth. The pumps are submerged into the water to draw untreated water into the suction bell and discharge it with minimal friction. Axial flow pumps are also widely used for on-shore and off-shore explorations of crude oil to meet the overseas logistics, domestic transportation and energy fuel requirements. In line with this, the pumps are also used for handling flammable, toxic and abrasive chemicals and fluids across automobile, construction and manufacturing industries, thereby contributing to the market growth. Other factors, including extensive infrastructural development, along with the implementation of favorable government policies, are positively influencing the axial flow pump market trends.

Key Market Segmentation:

IMARC Group provides an analysis of the key trends in each sub-segment of the global axial flow pump market report, along with forecasts at the global, regional and country level from 2025-2033. Our report has categorized the market based on type and application.

Breakup by Type:

- Miniwatt

- High Power

High power accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the type. This includes miniwatt and high power. According to the report, high power represents the largest segment.

High-power axial flow pumps are critical in businesses requiring large-scale water or fluid movement, such as water treatment plants, desalination plants, flood control, and irrigation systems. High power pumps are appropriate for these applications, which require handling big volumes of water with low pressure. Axial flow pumps are noted for their ability to move huge volumes of fluid with low head (pressure), while high power pumps are specifically designed to maximize efficiency in applications demanding continuous, high-capacity fluid transfer. Large infrastructure projects, such as power plants, dams, and municipal water supply systems, frequently need the usage of high-power axial flow pumps due to their capacity to manage large fluid flow rates and sustain long operational hours.

Breakup by Application:

- Domestic Water and Wastewater

- Petroleum

- Chemical

- Food and Beverage

- Others

Food and beverage holds the largest share of the industry

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes domestic water and wastewater, petroleum, chemical, food and beverage, and others. According to the report, food and beverage accounts for the largest market share.

During manufacturing procedures in the food and beverage (F&B) industry, significant volumes of liquids, such as water, juices, milk, and other beverages, are frequently moved. Axial flow pumps are especially efficient in low-pressure, high-flow applications, making them excellent for such duties. Axial flow pumps are noted for their ability to transfer fluids with low turbulence and shear, which is essential in this industry. This gentle handling helps to protect the quality and integrity of sensitive liquids like fruit juices and dairy products, which can be destroyed by high-pressure or high-turbulence systems. This sector adheres to strict cleanliness and safety regulations. Axial flow pumps are easily manufactured with materials and configurations that fulfill food-grade and sanitary standards, making them a popular choice for applications that require cleanliness and non-contaminating equipment.

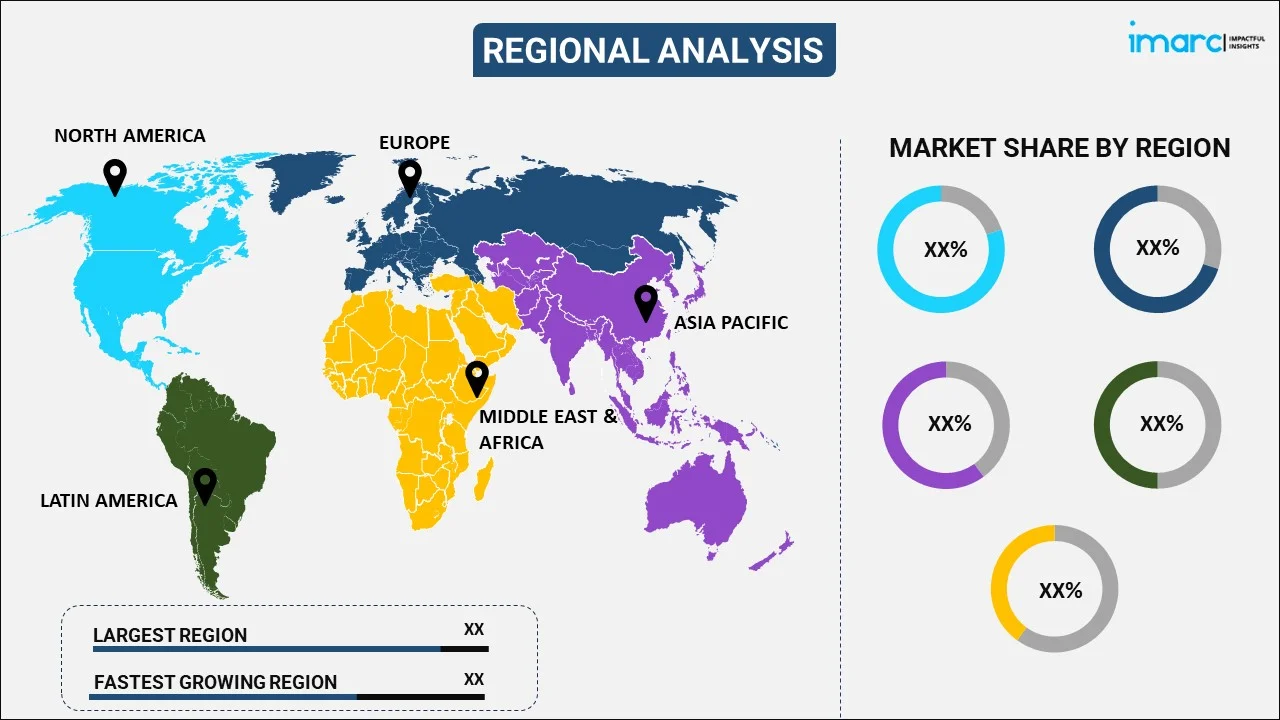

Breakup by Region:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific leads the market, accounting for the largest axial flow pump market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific represents the largest regional market for axial flow pump.

Asia Pacific is the largest region in the axial flow pump market, owing to fast industrialization, urbanization, and infrastructural development in countries, such as China, India, and Southeast Asian nations. The region's thriving water and wastewater treatment sector, fueled by rising population, urban growth, and environmental concerns, is driving the demand for axial flow pumps, which are essential for handling enormous quantities of water. Furthermore, the agricultural sector in Asia Pacific, notably in nations like India and China, relies significantly on irrigation systems, with axial flow pumps being frequently employed due to their efficiency in transferring large amounts of water. The region's expanding food and beverage (F&B) industry is further strengthening the market growth.

Competitive Landscape:

The competitive landscape of the industry has also been examined along with the profiles of the key players being Atlas Copco, Ebara Corporation, Grundfos Pumps India Private Ltd, ITT Inc., KSB SE & Co. KGaA, Leo Group Co., Ltd., Pentair, Sanlian Pump Company, Shanghai East Pump (Group) Co. Ltd., Sulzer Ltd., The Weir Group PLC and Wilo SE.

Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Segment Coverage | Type, Application, Region |

| Region Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Atlas Copco, Ebara Corporation, Grundfos Pumps India Private Ltd, ITT Inc., KSB SE & Co. KGaA, Leo Group Co., Ltd., Pentair, Sanlian Pump Company, Shanghai East Pump (Group) Co. Ltd., Sulzer Ltd., The Weir Group PLC and Wilo SE |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report

We expect the global axial flow pump market to exhibit a CAGR of 5.04% during 2025-2033.

The rising demand for axial flow pumps across various industries, such as oil and gas, chemical, food and beverage, etc., for irrigation, sewage treatment, cooling water pumps, and operating drainage system, is primarily driving the global axial flow pump market.

The sudden outbreak of the COVID-19 pandemic had led to the implementation of stringent lockdown regulations across several nations, resulting in the temporary closure of numerous end-use industries for axial flow pumps.

Based on the type, the global axial flow pump market has been segmented into miniwatt and high power, where high power currently holds the majority of the total market share.

Based on the application, the global axial flow pump market can be divided into domestic water and wastewater, petroleum, chemical, food and beverage, and others. Currently, food and beverage exhibits a clear dominance in the market.

On a regional level, the market has been classified into North America, Asia-Pacific, Europe, Latin America, and Middle East and Africa, where Asia-Pacific currently dominates the global market.

Some of the major players in the global axial flow pump market include Atlas Copco, Ebara Corporation, Grundfos Pumps India Private Ltd, ITT Inc., KSB SE & Co. KGaA, Leo Group Co., Ltd., Pentair, Sanlian Pump Company, Shanghai East Pump (Group) Co. Ltd., Sulzer Ltd., The Weir Group PLC, and Wilo SE.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)