Automotive Heat Shield Market Report by Material (Metallic, Non-Metallic), Product (Single Shell, Double Shell, Sandwich Type), Application (Exhaust System, Turbocharger, Under Bonnet, Engine Compartment, Under Chassis, and Others), Vehicle Type (Passenger Car, Commercial Vehicles, and Others), and Region 2025-2033

Automotive Heat Shield Market Size:

The global automotive heat shield market size reached USD 11.8 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 15.1 Billion by 2033, exhibiting a growth rate (CAGR) of 2.65% during 2025-2033. The stringent emission regulations, the rise of turbocharged engines, increasing demand for luxury vehicles, rapid advancements in material technology, the growth of electric vehicles (EVs), globalization of production standards, and the burgeoning aftermarket sector are some of the factors fostering the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 11.8 Billion |

| Market Forecast in 2033 | USD 15.1 Billion |

| Market Growth Rate 2025-2033 | 2.65% |

Automotive Heat Shield Market Analysis:

- Market Growth and Size: The global automotive heat shield market is experiencing substantial growth, driven by increasing vehicle production and the rising need for efficient heat management in modern vehicles, influenced by advancements in engine technologies and the escalating complexity of automotive designs.

- Major Market Drivers: The key market drivers include rising focus on vehicle lightweighting to improve fuel efficiency, enhanced safety standards, the need for effective heat management to prevent accidents and malfunctions increases, escalating consumer awareness of vehicle maintenance, increasing use of composite materials, expansion of automotive manufacturing, and growing popularity of off-road vehicles.

- Technological Advancements: Technological advancements in the automotive heat shield market are pivotal in offering a favorable automotive heat shield market outlook. Innovations in material science have led to the development of lighter, more efficient heat shields that offer superior thermal insulation. The integration of nanotechnology and the use of advanced composites and ceramics are revolutionizing heat shield designs, making them more effective and durable. Furthermore, the adoption of three-dimensional (3D) printing technology allows for the creation of complex, customized heat shield shapes, catering to the specific needs of different vehicle models.

- Industry Applications: The automotive heat shield finds extensive applications across various segments of the industry. It's crucial in passenger vehicles for enhancing comfort and safety by managing engine and exhaust heat. In commercial vehicles, heat shields are essential for protecting cargo and reducing the risk of overheating-related failures. The racing sector also relies heavily on advanced heat shielding to manage the extreme temperatures generated by high-performance engines.

- Key Market Trends: Growing trend to use eco-friendly materials in heat shield manufacturing, availability of customization in luxury vehicles, integration with noise, vibration, and harshness (NVH) solutions, increasing emphasis on designing aerodynamically efficient heat shields, rise in demand for high-performance sports cars, the expanding motorbike market, and the growing influence of digitalization in manufacturing are some of the key market trends.

- Geographical Trends: The North American market, particularly the United States, leads in the automotive heat shield market due to its large automotive industry, advanced manufacturing capabilities, and stringent emission and safety standards. Europe follows closely, with its strong emphasis on environmental regulations and high demand for luxury vehicles necessitating advanced heat shields. Asia-Pacific, led by China and India, is rapidly growing due to expanding vehicle production and increasing adoption of advanced automotive technologies in these regions.

- Competitive Landscape: The competitive landscape of the automotive heat shield market is characterized by the presence of both global players and regional manufacturers. Key players are engaged in intense competition, focusing on technological innovation, strategic partnerships, and expanding their product portfolios to meet diverse consumer needs.

Automotive Heat Shield Market Trends:

Stringent emission norms and regulations

Stringent emission norms and regulations are a primary driver of the global automotive heat shield market. Governments worldwide are implementing stricter emission standards to combat environmental pollution and climate change. These regulations often mandate significant reductions in vehicle emissions, including greenhouse gases and particulate matter. To comply with these standards, automotive manufacturers are compelled to adopt advanced heat management solutions, including heat shields. Heat shields play a crucial role in reducing thermal emissions by insulating components from excessive heat, especially in areas near engines and exhaust systems.

Increasing adoption of turbocharged engines

The increasing adoption of turbocharged engines is another significant driver for the automotive heat shield market growth. Turbochargers enhance engine performance by forcing extra air into the combustion chamber, thereby increasing power output. However, this process generates substantial heat, which can adversely affect engine components and overall vehicle performance. Heat shields are crucial in these scenarios, as they protect sensitive parts from the extreme temperatures produced by turbocharged engines. By effectively managing the heat, these shields help in maintaining the integrity and performance of the engine and other adjacent components. Additionally, turbochargers are becoming increasingly popular in smaller engines to boost efficiency and power, further escalating the demand for effective heat shielding solutions.

Growing demand for luxury and high-performance vehicles

The growing demand for luxury and high-performance vehicles significantly impacts the automotive heat shield market. They typically feature powerful engines and high-end components that generate considerable heat during operation. Effective heat management is crucial in these vehicles to ensure optimal performance, longevity of parts, and passenger comfort. Luxury and high-performance vehicles often require customized heat shields that offer superior heat resistance and durability. The demand for these vehicles is particularly strong in emerging markets and among affluent consumers, who seek advanced features and superior driving experiences. As a result, manufacturers are increasingly investing in research and development (R&D) to develop advanced heat shield solutions that meet the specific requirements of these high-end vehicles.

Advancements in material technology

Advancements in material technology significantly drive the automotive heat shield market demand as modern heat shields are no longer limited to traditional materials like aluminum or steel. The development and integration of lightweight, high-temperature resistant materials, such as advanced ceramics, composites, and specialty alloys have revolutionized heat shield design and functionality. These new materials offer superior heat insulation, reduced weight, and enhanced durability, which are essential for improving vehicle performance and fuel efficiency. The lightweight nature of these advanced materials is particularly crucial in the context of emission reduction and energy efficiency goals.

Automotive Heat Shield Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2025-2033. Our report has categorized the market based on the material, product, application, and vehicle type.

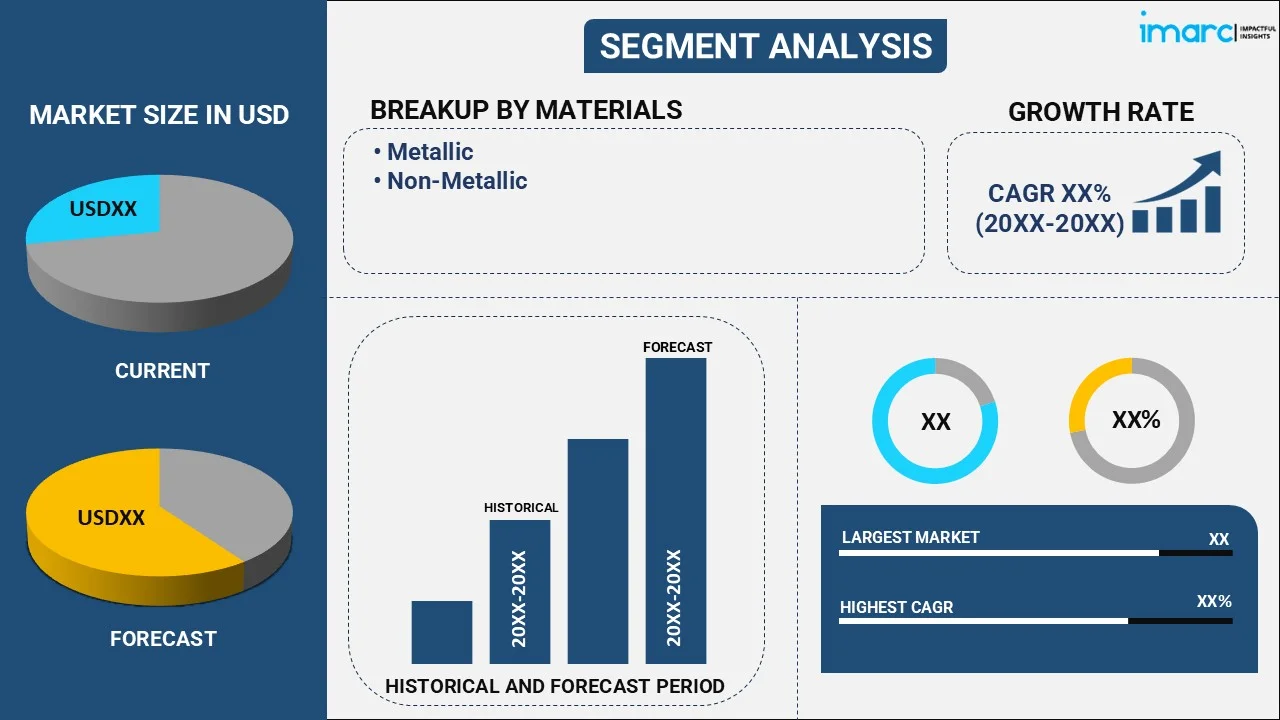

Breakup by Material:

- Metallic

- Non-Metallic

Metallic accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the material. This includes metallic and non-metallic. According to the report, metallic represented the largest segment.

The metallic segment is driven by the increasing demand for durable and high-strength materials in automotive heat shields. Metallic heat shields, typically made from materials like aluminum and steel, are favored for their robustness and ability to withstand high temperatures. The segment benefits from the widespread availability and proven performance of these materials in heat management applications. The development of lightweight metallic alloys further propels this segment, aligning with the automotive industry's shift towards lighter vehicles for improved fuel efficiency and reduced emissions. Moreover, the cost-effectiveness and recyclability of metallic materials make them a preferred choice in various automotive applications, from passenger cars to heavy-duty vehicles.

The non-metallic segment is driven by the increasing need for lightweight, high-performance materials in the automotive industry. Non-metallic heat shields, often made from advanced ceramics, composites, and polymers, are gaining popularity due to their superior thermal insulation properties and lighter weight compared to traditional metallic shields. The segment benefits from ongoing R&D in material science, leading to the creation of materials that can withstand extreme temperatures while minimizing the overall weight of the vehicle. The growing focus on fuel efficiency and emission reduction in the automotive sector further amplifies the demand for non-metallic heat shields, as they contribute significantly to reducing the vehicle's weight and improving its performance.

Breakup by Product:

- Single Shell

- Double Shell

- Sandwich Type

Single shell accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the product. This includes single shell, double shell, and sandwich type. According to the report, single shell represented the largest segment.

The single shell segment is driven by the increasing demand for cost-effective and lightweight solutions in the automotive industry. The segment's growth is primarily attributed to the simplicity and effectiveness of single shell heat shields in managing thermal emissions in vehicles. These heat shields are typically made from a single layer of heat-resistant material, such as aluminum or steel, which makes them lighter and more affordable compared to their multi-layered counterparts. The single shell design is particularly appealing in budget and compact car segments, where cost efficiency is a major consideration. Additionally, the ease of manufacturing and installation of single shell heat shields also contributes to their popularity.

The double shell segment is driven by the increasing requirement for superior heat insulation and noise reduction in modern vehicles. This segment benefits from the enhanced performance offered by double shell heat shields, which consist of two layers of material with an insulating air gap in between. The design provides better thermal protection compared to single shell designs, making it ideal for high-performance and luxury vehicles, where engine heat and noise can be significant. The double layer effectively traps heat and dampens engine noise, contributing to a more comfortable and quieter driving experience.

The sandwich type segment is driven by the increasing demand for advanced heat management solutions in high-end and performance-oriented vehicles. This segment capitalizes on the superior heat insulation and vibration damping capabilities of sandwich type heat shields. These shields typically comprise multiple layers, including a heat-reflective surface, insulating material, and a protective outer layer. The sandwich design's ability to absorb and dissipate heat while reducing vibration and noise makes it highly suitable for premium vehicles, where customer expectations for comfort and performance are high.

Breakup by Application:

- Exhaust System

- Turbocharger

- Under Bonnet

- Engine Compartment

- Under Chassis

- Others

Engine compartment accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the application. This includes exhaust system, turbocharger, under bonnet, engine compartment, under chassis, and others. According to the report, engine compartment represented the largest segment.

The engine compartment segment is driven by the need to protect critical engine components from extreme operational heat. Effective heat management in this segment is vital for maintaining engine efficiency, reducing the risk of overheating, and extending the lifespan of engine parts. With the advent of high-performance engines and the increasing use of turbochargers, the thermal load in engine compartments has intensified, necessitating robust heat shielding. Additionally, the shift towards more compact engine designs in modern vehicles places greater emphasis on efficient space utilization and heat dissipation within the engine compartment.

The exhaust system segment is driven by the increasing emphasis on emission control and noise reduction in vehicles. This segment is crucial for managing the high temperatures and gases emitted by the engine. With tightening global emission norms, such as Euro VI and Tier 4, manufacturers are compelled to innovate in exhaust heat management. Advanced materials that can withstand extreme temperatures and corrosive exhaust gases are in high demand.

The turbocharger segment is driven by the increasing adoption of downsized and turbocharged engines to meet fuel efficiency and emission standards. These engines, while more efficient, generate significant heat that needs to be managed effectively to maintain engine integrity and performance. Heat shields in this segment are designed to protect critical engine components and the vehicle's body from the intense heat produced by turbochargers.

The under bonnet segment is driven by the increasing complexity and density of components within the engine compartment. As modern vehicles incorporate more technology and larger engines into a limited space, managing the resultant heat becomes critical. Effective heat shields in this area protect sensitive electronic components, reduce the thermal impact on the engine, and prevent heat-related degradation of surrounding parts.

The under chassis segment is driven by the need to protect the vehicle undercarriage from heat exposure and environmental elements. Heat shields in this area are crucial for preventing heat transfer from the exhaust system to the vehicle floor, thereby ensuring passenger comfort and safety. The increasing use of lightweight and composite materials in vehicle construction also necessitates the development of compatible heat shielding solutions for the under chassis area.

The others segment is driven by the diverse and specialized heat management needs in various areas of a vehicle. The segment includes areas like the transmission system, fuel lines, and brake systems, where effective heat management is critical for safety and performance.

Breakup by Vehicle Type:

- Passenger Car

- Commercial Vehicles

- Others

Passenger car accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the vehicle type. This includes passenger car, commercial vehicles, and others. According to the report, passenger car represented the largest segment.

The passenger car segment is driven by the increasing demand for fuel-efficient and environmentally friendly vehicles, stringent emission norms, and the rising consumer preference for comfort and safety. As governments worldwide impose tougher emission standards, manufacturers are compelled to incorporate advanced heat management systems like heat shields to maintain compliance. Additionally, the growing consumer awareness about the environmental impact of vehicles has led to a surge in demand for eco-friendly cars, further boosting the need for efficient heat shielding.

The commercial vehicle segment is driven by the increasing demand for efficient transportation of goods and passengers, the need for durable and reliable vehicles, and regulatory pressures for lower emissions and safer vehicles. The growth in e-commerce and the consequent rise in logistics and freight services have led to a higher demand for commercial vehicles, which require robust heat management systems to ensure the longevity and reliability of the vehicle.

The others segment, encompassing vehicles like two-wheelers, off-road vehicles, and racing cars, is driven by the increasing popularity of recreational and sports vehicles, the growing demand for high-performance vehicles, and the unique heat management challenges these vehicles present. Off-road and sports vehicles, often subjected to extreme conditions, require robust heat management systems to maintain performance and prevent overheating. Heat shields in these vehicles are designed to withstand harsh environments while ensuring optimal engine performance.

Breakup by Region:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific leads the market, accounting for the largest automotive heat shield market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific accounted for the largest market share.

The Asia-Pacific automotive heat shield market is driven by the increasing vehicle production and expanding automotive sector in countries like China, India, and Japan. Rapid industrialization, growing middle-class population, and rising disposable incomes in these countries contribute to a higher demand for vehicles, thereby boosting the heat shield market. Furthermore, Asia-Pacific's role as a manufacturing hub for global automotive companies, combined with increasing exports, supports the growth of the heat shield market

The North America region is driven by the increasing demand for vehicles equipped with advanced safety and performance features. Stringent emission and fuel efficiency regulations in countries like the United States and Canada necessitate the integration of effective heat management systems in vehicles. The presence of major automobile manufacturers and a mature automotive industry fosters innovation and adoption of advanced heat shield technologies.

Europe’s market is driven by the increasing emphasis on environmental sustainability and stringent emission norms, such as the Euro 6 standards. The presence of leading luxury and performance vehicle manufacturers in countries like Germany, France, and Italy necessitates the use of advanced heat shielding solutions. The region’s focus on reducing vehicle weight for better fuel efficiency further drives the demand for innovative, lightweight heat shield materials.

Latin America’s automotive heat shield market is driven by the increasing local production and assembly of vehicles in countries like Brazil, Mexico, and Argentina. The growing automotive industry, coupled with improving economic conditions and increased foreign investment, stimulates the demand for automotive heat shields.

The Middle East and Africa automotive heat shield market is driven by the increasing demand for vehicles due to economic diversification and urbanization, especially in countries like Saudi Arabia, UAE, and South Africa. The region's harsh climatic conditions necessitate robust heat management systems in vehicles, thereby fueling the heat shield market.

Leading Key Players in the Automotive Heat Shield Industry:

Key players in the automotive heat shield market are actively engaging in a range of strategic initiatives to strengthen their market positions. These include extensive R&D to innovate and introduce advanced materials and designs that enhance the efficiency and effectiveness of heat shields. Major companies are investing in lightweight, high-temperature resistant materials like advanced composites and ceramics to meet the evolving demands of modern vehicles, especially in the context of fuel efficiency and emission reduction. Collaborations and partnerships with automotive manufacturers and material scientists are also common, aiming to develop customized solutions for specific vehicle requirements. Additionally, there is a noticeable trend towards digitalization and automation in manufacturing processes to increase production efficiency and reduce costs. Furthermore, the players are actively participating in the growing aftermarket sector, catering to the replacement and customization needs of the existing vehicle fleet.

The market research report has provided a comprehensive analysis of the competitive landscape. Detailed profiles of all major companies have also been provided. Some of the key players in the market include:

- Autoneum

- Carcoustics (Liaoning Dare Industrial Company Ltd.)

- Dana Incorporated

- DuPont de Nemours Inc

- ElringKlinger AG

- HAPPICH GmbH (Pelzer Acoustic Products GmbH)

- Lydall Inc.

- Morgan Advanced Materials Plc

- NICHIAS Corporation

- Talbros Automotive Components Ltd.

- Tenneco Inc.

- Zircotec

(Please note that this is only a partial list of the key players, and the complete list is provided in the report.)

Latest News:

- In November 2020: In November 2020, Dana Incorporated signed a definitive agreement to purchase a portion of the thermal-management business of Modine Manufacturing Company. This strategic acquisition is indicative of Dana's efforts to expand its capabilities and market reach in thermal-management technologies, which are crucial for automotive heat shields.

- In 2020: Talbros Automotive entered into a Technical Assistance Agreement (TAA) with its Japanese partner, Sanwa Packing Industry Co. Ltd, for the development of lightweight aluminum heat shields.

- In November 2023: EKPO Fuel Cell Technologies (EKPO), a part of ElringKlinger AG, received funding of up to EUR 177 million from the Federal Ministry for Digital and Transport as part of the European “IPCEI Hydrogen” program.

Automotive Heat Shield Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Materials Covered | Metallic, Non-Metallic |

| Products Covered | Single Shell, Double Shell, Sandwich Type |

| Applications Covered | Exhaust System, Turbocharger, Under Bonnet, Engine Compartment, Under Chassis, Others |

| Vehicle Types Covered | Passenger Car, Commercial Vehicles, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Autoneum, Carcoustics (Liaoning Dare Industrial Company Ltd.), Dana Incorporated, DuPont de Nemours Inc, ElringKlinger AG, HAPPICH GmbH (Pelzer Acoustic Products GmbH), Lydall Inc., Morgan Advanced Materials Plc, NICHIAS Corporation, Talbros Automotive Components Ltd., Tenneco Inc., Zircotec, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the global automotive heat shield market performed so far, and how will it perform in the coming years?

- What are the drivers, restraints, and opportunities in the global automotive heat shield market?

- What is the impact of each driver, restraint, and opportunity on the global automotive heat shield market?

- What are the key regional markets?

- Which countries represent the most attractive automotive heat shield market?

- What is the breakup of the market based on the material?

- Which is the most attractive material in the automotive heat shield market?

- What is the breakup of the market based on product?

- Which is the most attractive product in the automotive heat shield market?

- What is the breakup of the market based on the application?

- Which is the most attractive application in the automotive heat shield market?

- What is the breakup of the market based on the vehicle type?

- Which is the most attractive vehicle type in the automotive heat shield market?

- What is the competitive structure of the market?

- Who are the key players/companies in the global automotive heat shield market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the automotive heat shield market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global automotive heat shield market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the automotive heat shield industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)