Adhesive Equipment Market Size, Share, Trends, and Forecast by Product, Application, Distribution Channel, and Region, 2025-2033

Adhesive Equipment Market Size and Share:

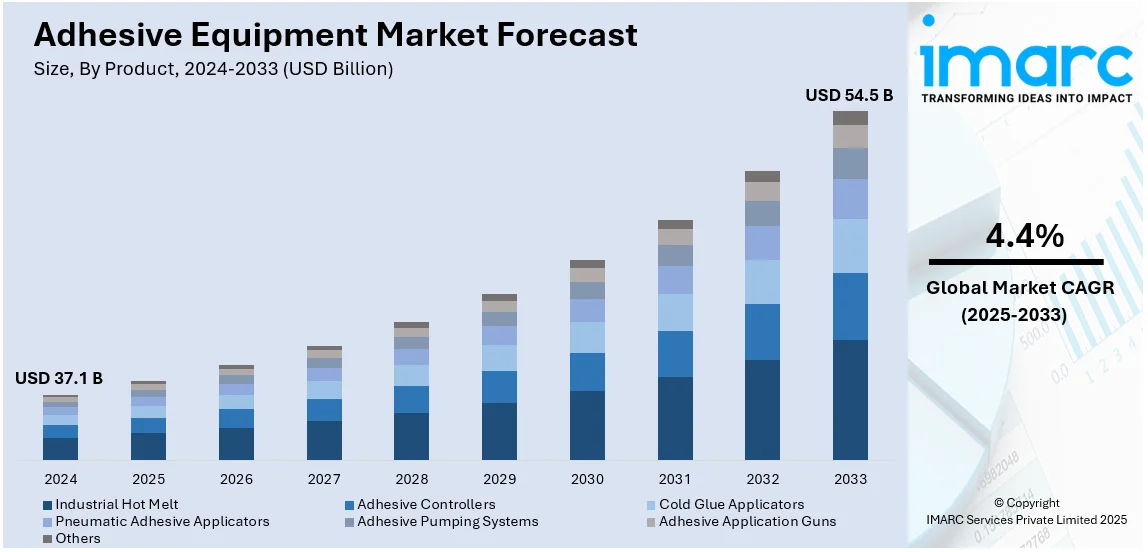

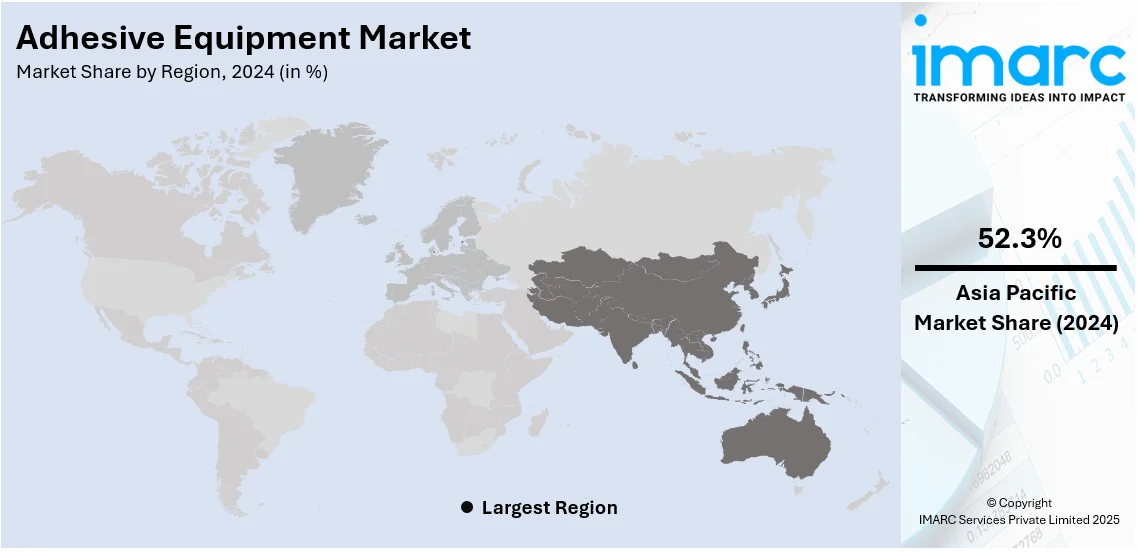

The global adhesive equipment market size was valued at USD 37.1 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 54.5 Billion by 2033, exhibiting a CAGR of 4.4% from 2025-2033. Asia Pacific currently dominates the market. The growth of the Asia Pacific region is driven by expanding manufacturing sectors, increased demand for packaging, automotive innovations, and a strong focus on automation and sustainability.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 37.1 Billion |

|

Market Forecast in 2033

|

USD 54.5 Billion |

| Market Growth Rate 2025-2033 | 4.4% |

The shift towards automation, particularly in sectors like automotive, electronics, and consumer goods, is driving the need for high-performance adhesive equipment. Automation helps in streamlining the entire production process, thereby ensuring consistent quality and faster output, further boosting the demand for adhesive equipment that can handle high-volume applications. Moreover, the increasing complexity in product designs and a demand for higher precision in manufacturing processes require customized adhesive equipment. Industries are seeking solutions that can apply adhesives with greater accuracy, flexibility, and speed, which, in turn, boosts the need for specialized adhesive equipment tailored to meet specific production requirements. Besides this, the growing focus on sustainability and environment-friendly products is catalyzing the demand for eco-conscious adhesives. Companies are investing in adhesive equipment that can efficiently handle biodegradable and low-volatile organic compound (VOC) adhesives, aligning with environmental regulations.

The United States plays a crucial role in the market, driven by the continuous development in adhesive technologies and application methods. Advances in automation, precision, and smart adhesive dispensing systems are driving the demand for more advanced adhesive equipment in various sectors, including automotive, electronics, and packaging. In addition, many industries are using robots for tasks such as adhesive dispensing. These robots improve precision, speed, and efficiency while reducing human error, making them essential for high-quality production processes. In 2024, Aim Robotics established Aim Robotics US in Nashville, Tennessee, through a collaboration with BlueBay Automation. The firm focuses on providing solutions for collaborative robots (cobots), especially in the management of materials such as adhesives, sealants, and lubricants. This expansion will offer manufacturers in the US localized assistance for precision dispensing automation in sectors like automotive and electronics.

Adhesive Equipment Market Trends:

Growing demand across diverse industries

The market for adhesive equipment is seeing strong growth driven by rising demand in various sectors, such as automotive, packaging, construction, electronics, healthcare, and aerospace. These sectors are relying on adhesives for their flexibility, effectiveness, and capacity to create robust, long-lasting connections. The escalating demand for high-strength and lightweight materials, crucial in contemporary manufacturing techniques, is additionally driving market expansion. The worldwide smart manufacturing industry, estimated at USD 358.3 billion in 2024, is driving the need for sophisticated adhesive machinery, as automation and precise dispensing technologies are crucial for enhancing production effectiveness. Adhesives provide various advantages, including increased product longevity, minimized vibrations, and better visual appeal, positioning them as a perfect choice for numerous applications. As industries progressively look for affordable, environmentally friendly options to conventional mechanical fasteners, adhesives remain the favored selection. The extensive usage in various industries is propelling the adhesive equipment market, accelerating advancement and expansion.

Emphasis on sustainable and eco-friendly solutions

Sustainability is rapidly emerging as a crucial issue for industries globally, and this focus on environment-friendly methods is driving market expansion. As per PwC, almost 85% of individuals indicate they are facing the disruptive impacts of climate change, leading more individuals to focus on sustainability, with 46% opting for more eco-friendly products to lessen their ecological footprint. Adhesive technologies are progressively being formulated and utilized as they provide eco-friendly options compared to conventional bonding techniques. Numerous adhesives are free from solvents and exhibit low or no volatile organic compound (VOC) emissions, which makes them more environment-friendly during their application and usage. Moreover, using adhesives typically leads to less material waste than mechanical fasteners, which supports the worldwide movement for conservation and waste minimization. Firms from various sectors are acknowledging the significance of sustainable practices, not just for adhering to regulations but also to improve their brand reputation and attract environmentally aware individuals. Furthermore, the growing need for adhesive machinery that promotes sustainable and environment-friendly bonding options is driving innovation within the adhesive sector.

Technological advancements and automation

Technological advancements in equipment and automation are revolutionizing the adhesive application process, supporting the market growth. Automation and robotics enhance the accuracy, uniformity, and efficiency of adhesive application, minimizing human mistakes, and guaranteeing superior product quality. Contemporary adhesive machinery combines sophisticated sensors, tracking systems, and accurate dispensing tools that guarantee optimal adhesive application, reducing waste and enhancing overall efficiency. Furthermore, the incorporation of internet of things (IoT) technology allows for real-time oversight and management of adhesive processes, promoting data-driven choices and improving efficiency while minimizing downtime. The worldwide IoT market, estimated at USD 1,022.6 billion in 2024, is essential in revolutionizing manufacturing processes, enabling producers to oversee adhesive application from a distance and ensure uniform quality. The growing implementation of automation enhances efficiency and lowers labor expenses, rendering adhesive solutions more affordable and attractive to manufacturers. This trend is driving the need for sophisticated adhesive machinery in multiple sectors, thereby strengthening the market growth.

Adhesive Equipment Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global adhesive equipment market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on product, application, and distribution channel.

Analysis by Product:

- Industrial Hot Melt

- Adhesive Controllers

- Cold Glue Applicators

- Pneumatic Adhesive Applicators

- Adhesive Pumping Systems

- Adhesive Application Guns

- Others

Industrial hot melt holds the biggest market share because of its versatile and efficient bonding properties, which make it ideal for high-speed, high-volume production processes across various industries. Its fast-setting nature allows for quick assembly, improving overall productivity and minimizing production time. Hot melt adhesive offers strong bonds on a variety of substrates, including paper, plastic, and metal, making it highly suitable for packaging, automotive, and electronics manufacturing. The ability to perform without the need for solvents or curing agents makes hot melt adhesive environment-friendly and cost-effective. Additionally, its resistance to temperature fluctuations, moisture, and other environmental factors enhances the durability of the bonds, making it a preferred choice for demanding applications. As automation in manufacturing continues to grow, the demand for fast, reliable, and efficient adhesive solutions like industrial hot melt is expected to remain strong, solidifying its dominant position in the market.

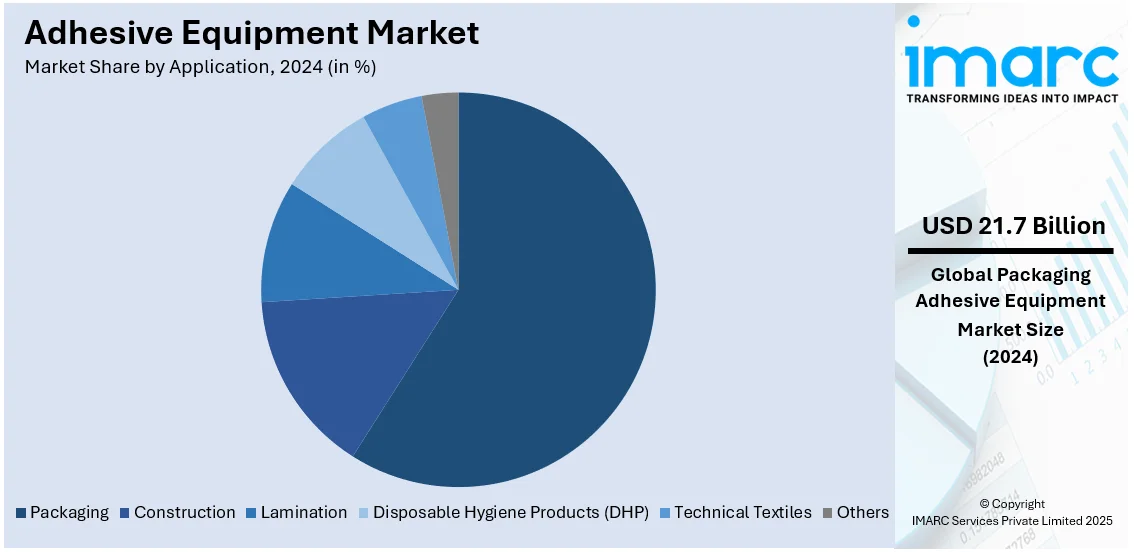

Analysis by Application:

- Packaging

- Construction

- Lamination

- Disposable Hygiene Products (DHP)

- Technical Textiles

- Others

Packaging represents the largest segment attributed to its essential role in securing products for transportation, storage, and sale. Adhesives are important for labeling, sealing, and securing packaging materials, ensuring product integrity and safety during handling. The increasing demand for innovative packaging solutions, such as tamper-proof seals, child-resistant packaging, and convenient formats, is driving the need for advanced adhesive technologies. Adhesive equipment is vital in automating packaging processes, increasing efficiency, and reducing waste, which is critical in high-volume production environments. Additionally, the rise in e-commerce is amplifying the requirement for protective and durable packaging, further boosting demand for adhesives. With packaging being a key factor in product marketing and user experience, the emphasis on attractive, functional, and sustainable packaging solutions continues to grow, making it a dominant application segment in the market.

Analysis by Distribution Channel:

- Supermarket and Hypermarket

- Retail Stores

- Online Stores

- Others

Retail stores exhibit a clear dominance in the market owing to their direct accessibility to buyers, providing a convenient shopping experience for both professional and do-it-yourself (DIY) users. These stores offer a wide array of adhesive products, ranging from basic household adhesives to specialized equipment used in crafts, repairs, and industrial applications. The ease of purchasing in-person allows buyers to quickly select products based on their immediate needs, with the advantage of immediate availability. Retail stores also provide valuable client support, including product demonstrations, advice, and hands-on experiences, which are essential for users unfamiliar with the adhesive tools. Moreover, the growing trend of hobbyist and DIY activities are driving the demand for adhesive products in retail settings. As retail stores continue to adapt to user preferences and offer personalized services, they remain a key distribution channel, ensuring a steady supply of adhesive equipment to both individuals and small businesses.

Analysis by Region:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

The Asia Pacific region leads the market owing to its significant involvement in vital sectors like automotive, packaging, and construction. The manufacturing sector in the region is progressively implementing advanced adhesive technologies to enhance efficiency and product quality. With a strong supply chain and economical manufacturing capabilities, Asia Pacific serves as a key center for the production and utilization of adhesive equipment. In addition, the area's increasing emphasis on sustainability and green solutions is encouraging businesses to create innovative, eco-conscious adhesive products, thereby boosting the need for specialized machinery. The growing focus on automation and accuracy in manufacturing operations is further driving market expansion, as companies look for adhesive machinery that provides enhanced consistency and lower operational expenses. Moreover, the growing e-commerce industry in the Asia Pacific region increases the need for packaging solutions, with adhesives being vital in delivering strong and effective seals for various products. According to the India Brand Equity Foundation (IBEF), the Indian e-commerce industry is projected to reach US$ 325 billion by 2030, experiencing significant growth.

Key Regional Takeaways:

United States Adhesive Equipment Market Analysis

The US adhesive equipment market benefits significantly from the booming e-commerce sector, with nearly 14 Million e-commerce sites accounting for approximately 53% of all global websites, far surpassing any other country. This thriving digital retail ecosystem drives high demand for advanced packaging solutions, where adhesives play a critical role in ensuring secure and efficient product handling. Additionally, the construction industry’s focus on energy-efficient buildings continues to expand adhesive applications, particularly for insulation and structural bonding. The automotive sector further propels market growth by emphasizing lightweight vehicle designs to meet fuel efficiency and sustainability targets, encouraging the adoption of adhesive technologies over traditional mechanical fasteners. Technological advancements, such as hot-melt adhesive equipment and automated dispensing systems, enhance market dynamics by improving precision, operational efficiency, and overall performance. Furthermore, stringent environmental regulations are driving the transition to eco-friendly adhesive solutions, prompting innovation in equipment design and formulation. The US also benefits from the presence of major industry players and robust R&D initiatives, which continuously foster the development of high-performance adhesive systems. These factors collectively position the US as a leader in the global adhesive equipment market, ensuring sustained growth and competitiveness across multiple industries.

Europe Adhesive Equipment Market Analysis

The adhesive equipment market in Europe is heavily impacted by the increasing demand from the packaging sector, with the paper packaging market projected to reach USD 54.5 Billion by 2024. The rise in demand, fueled by the growing choice for recyclable and biodegradable materials, has greatly enhanced the utilization of cutting-edge adhesive technologies in packaging uses. The automotive industry also plays an important part, as its emphasis on lightweight materials and electric vehicles requires high-performance adhesives to achieve energy efficiency and sustainability benchmarks. In a similar manner, the construction sector is fostering expansion via eco-friendly building efforts, employing adhesives for insulation and other energy-saving materials. Along with packaging and construction, the healthcare and electronics industries are driving the need for precision adhesive machinery for medical devices and consumer electronics. Innovations in technology, including automated dispensing solutions and environmentally-friendly adhesive compositions, boost the market by increasing efficiency and sustainability. The strict environmental regulations in Europe promote ongoing innovation, with major companies investing in R&D to create advanced adhesive systems.

Asia Pacific Adhesive Equipment Market Analysis

The market for adhesive equipment in the Asia-Pacific area is propelled by fast urban growth, industrial development, and infrastructure expansion. As per the World Bank, East Asia and the Pacific is the fastest urbanizing region globally, experiencing an average yearly urbanization rate of 3%. This city expansion drives demand in major sectors like construction, packaging, automotive, and electronics. The growth of infrastructure in nations such as China, India, and Vietnam led to a rise in adhesive usage in construction endeavors, especially for insulation, bonding, and energy-efficient materials. The flourishing e-commerce sector has heightened the need for advanced packaging solutions, where adhesives play a crucial role. Likewise, the emphasis in the automotive sector on electric vehicles speeds up the use of adhesive technologies for lightweight and resilient designs. Moreover, the electronics sector gains advantages from adhesives employed in device construction and miniaturization. Affordable manufacturing, plentiful raw materials, and increasing environmental consciousness also propel the market, encouraging the transition to sustainable adhesive options.

Latin America Adhesive Equipment Market Analysis

The adhesive equipment market in Latin America is bolstered by crucial sectors like packaging, construction, and automotive. Rapid urban growth, with around 80% of Latin American countries now urbanized according to BBVA Research, has increased the demand for consumer goods and infrastructure, driving the need for creative packaging solutions and adhesives in the building industry. The increasing emphasis on sustainability likewise encourages the use of environmentally friendly adhesives. Moreover, the automotive sector is incorporating adhesives in order to create lightweight vehicle designs that achieve fuel efficiency targets. Due to urban expansion and a rising focus on sustainability, Latin America offers a robust market for adhesive machinery.

Middle East and Africa Adhesive Equipment Market Analysis

The adhesive equipment market in the Middle East and Africa (MENA) is driven by urbanization, with the region already 64% urbanized according to the World Bank. This rapid urbanization, particularly in countries like the UAE and Saudi Arabia, fosters demand across industries such as construction, packaging, and automotive. In modern construction, adhesives are becoming more prevalent in building materials and infrastructure initiatives. The automotive sector’s need for lightweight as well as fuel-efficient vehicles further accelerates adhesive adoption. Additionally, growing environmental consciousness promotes the use of eco-friendly adhesive technologies, creating a positive growth trajectory for the market in MENA.

Competitive Landscape:

Major market participants are dedicating resources to research activities aimed at boosting adhesive efficiency, refining application methods, and developing sustainable alternatives. Strategic alliances, mergers, and joint ventures are frequently pursued as businesses seek to broaden their market presence and enhance their product offerings. In response to the growing need for automation and efficiency, various companies are launching sophisticated, automated adhesive dispensing and application solutions. Moreover, there is a greater focus on sustainability, as companies create adhesives that minimize environmental effects and meet strict regulations. They are concentrating on innovation, diversifying products, and advancing technology to satisfy changing industry needs. In 2024, Delo introduced the Delo-DOT PN5 LV pneumatic jet valve, created for accurate dispensing of low-viscosity adhesives in compact applications. It provides droplet dimensions as tiny as 1 nl and functions at frequencies up to 250 Hz. The small size, light construction, and touch-free dispensing enable quick, accurate applications in manufacturing systems.

The report provides a comprehensive analysis of the competitive landscape in the adhesive equipment market with detailed profiles of all major companies, including:

- 3M Company

- Adhesive & Equipment Inc.

- Atlas Copco

- Dymax Corporation

- Glue Machinery Corporation

- Graco Inc.

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- ITW Dynatec

- Nordson Corporation

- Robatech AG

- Valco Cincinnati Inc.

Latest News and Developments:

- September 2024: Henkel has revealed Pattex No More Nails Stick & Peel, a removable adhesive that can hold up to 6 kilograms on various surfaces such as tile and PVC. Water-resistant and easily peelable without damage, it allows for quick, tool-free decoration. Its unique formulation provides strong initial tack while ensuring easy removal, making it ideal for DIY projects, especially in rented spaces where surface damage is a concern.

- September 2024: Power Adhesives has launched its biodegradable hot melt adhesive, Tecbond 2014B, designed for packaging applications. Made with 44% bio-based materials and certified to ASTM D6400 and EN13432, it offers high tack and fast setting speed while being fully compostable without microplastics. The adhesive has been authorized for indirect food contact.

Adhesive Equipment Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Products Covered | Industrial Hot Melt, Adhesive Controllers, Cold Glue Applicators, Pneumatic Adhesive Applicators, Adhesive Pumping Systems, Adhesive Application Guns, Others |

| Applications Covered | Packaging, Construction, Lamination, Disposable Hygiene Products (DHP), Technical Textiles, Others |

| Distribution Channels Covered | Supermarket and Hypermarket, Retail Stores, Online Stores, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | 3M Company, Adhesive & Equipment Inc., Atlas Copco, Dymax Corporation, Glue Machinery Corporation, Graco Inc., H.B. Fuller Company, Henkel AG & Co. KGaA, ITW Dynatec, Nordson Corporation, Robatech AG, Valco Cincinnati Inc., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the adhesive equipment market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global adhesive equipment market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the adhesive equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The adhesive equipment market was valued at USD 37.1 Billion in 2024.

IMARC estimates the adhesive equipment market to exhibit a CAGR of 4.4% during 2025-2033, reaching USD 54.5 Billion by 2033.

The market is driven by the shift toward automation in manufacturing, increased demand for precision adhesive equipment, growth in packaging and automotive innovations, and the rising emphasis on sustainability with eco-friendly adhesive solutions.

Asia Pacific currently dominates the market. This dominance is fueled by the region's growing manufacturing sectors, rising demand for packaging solutions, advancements in automation, and focus on sustainable products.

Some of the major players in the adhesive equipment market include 3M Company, Adhesive & Equipment Inc., Atlas Copco, Dymax Corporation, Glue Machinery Corporation, Graco Inc., H.B. Fuller Company, Henkel AG & Co. KGaA, ITW Dynatec, Nordson Corporation, Robatech AG, and Valco Cincinnati Inc., among others.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)