Global UV Tapes Market Expected to Reach USD 1,014.2 Million by 2033 – IMARC Group

Global UV Tapes Market Statistics, Outlook and Regional Analysis 2025-2033

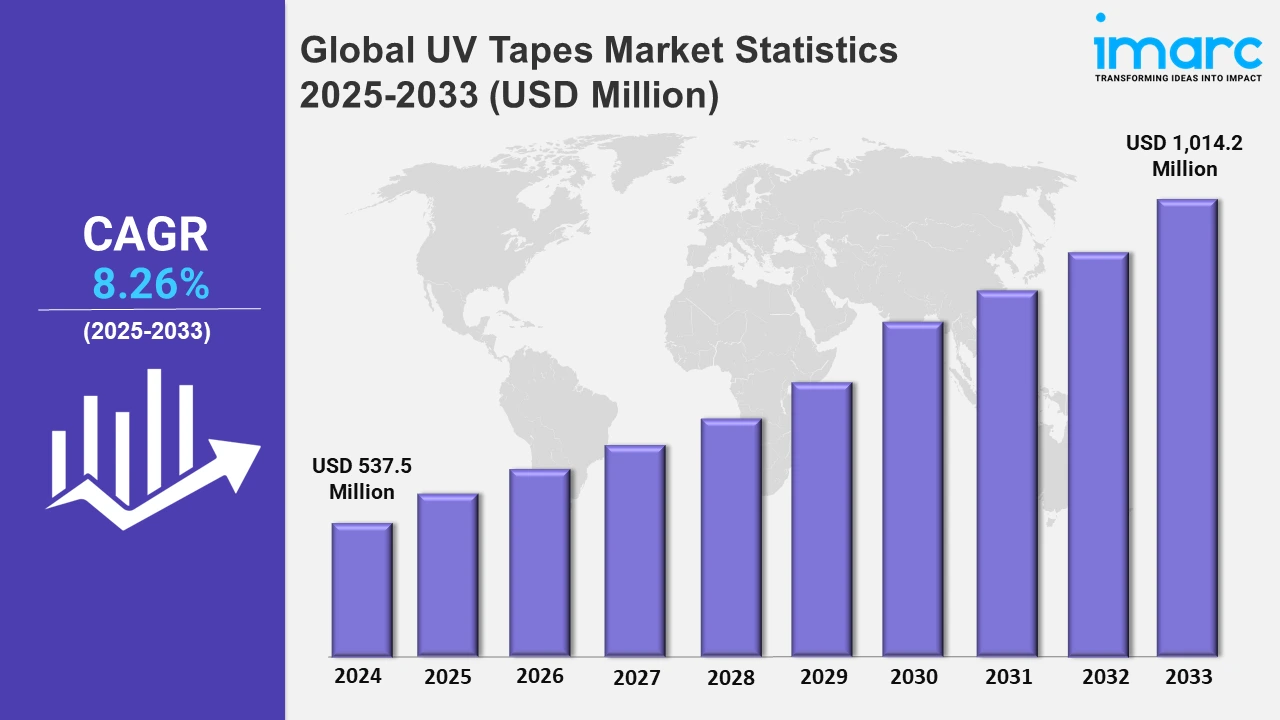

The global UV tapes market size was valued at USD 537.5 Million in 2024, and it is expected to reach USD 1,014.2 Million by 2033, exhibiting a growth rate (CAGR) of 8.26% from 2025 to 2033.

To get more information on this market, Request Sample

Ultraviolet (UV) tapes are widely used in the semiconductor and microelectronics industries owing to their unique characteristics and functions while accomplishing a range of operations including, mounting of UV sensitive critical components, such as semiconductor wafers. UV tapes hold semiconductor wafers during dicing which permits for cuts with no cracks or chipping or damage to soft materials. UV tapes can also be used in extreme environments, as they are able to withstand high temperatures, harsh chemicals and a lot of mechanical stress. These UV tapes do not leave behind any or very minimal amount of residue, thereby, giving a clean surface for the semiconductors, as even a spec of dirt will make the whole device useless. When combined with other equipment, UV tapes assist in the protection of wafers and components while grinding or etching, decreasing the material waste and the need for reworking, which saves time and money for manufacturers. The rising shift towards miniaturization in electronics, which requires extreme precision in semiconductor fabrication, is catalyzing the demand for UV tapes in handling intricate processes. As per the IMARC Group’s report, the global semiconductor market is expected to reach USD 1,221.2 Billion by 2033.

UV tapes are important for ensuring the effective production as well as maintenance of renewable energy systems. They find applications in the manufacturing of photovoltaic (PV) solar panels, where they are employed to bond PV cells together and laminate them for extra protection while providing structural elements that resist UV radiation. During the solar panels’ installation, scratches, debris, and other elements capable of damaging the surface are avoided with the help of UV tapes. They are also employed in wind turbines during their shipment and assembly as well as during repair, to cover parts. For wind turbines, UV tapes protect joints from mechanical stress during operations and minimize the risk of failure due to vibration or external forces. Innovations in eco-friendly and recyclable UV tape materials, coupled with the increasing adoption of sustainability practices, particularly in the renewable energy sector, are further impelling the market growth. The IMARC Group’s report shows that the global renewable energy market is expected to reach USD 1,818.4 Billion by 2033.

Global UV Tapes Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia-Pacific accounts for the largest market share driven by its advanced semiconductor and electronics manufacturing hubs, innovations in technology, and the rising number of key manufacturers in countries like China, Japan, South Korea, and Taiwan.

Asia-Pacific UV Tapes Market Trends:

The Asia-Pacific region enjoys the leading position in the UV tapes market due to the burgeoning electronic, automotive, and semiconductor industries. Countries like China, Japan, South Korea, and Taiwan are major hubs for semiconductor manufacturing, which is driving the demand for UV tapes in wafer dicing and chip packaging. The region benefits from a well-established base of consumer electronics production. Additionally, the thriving automotive industry, which include hybrid and electric vehicles (HEVs), is catalyzing the demand for UV tapes in surface protection and component assembly applications. Government initiatives to boost local manufacturing and technological advancements in countries like India and Vietnam are also supporting the market growth. The integration of AI to develop advanced UV tape formulations tailored as per specific applications, is bolstering the market growth. According to the IMARC Group’s report, the Asia-Pacific artificial intelligence market is projected to exhibit a growth rate (CAGR) of 21.1% during 2024-2032.

North America UV Tapes Market Trends:

The UV tapes industry has a substantial market share in North America due to the presence of developed industries, such as aerospace, electronics, and healthcare. The USA and Canada are promoting the use of UV tapes in high precision sectors like microelectronics and medical device production. People are getting aware about the environmental impacts and advocates the use of UV tapes because of its solvent-free and ecofriendly characteristics.

Europe UV Tapes Market Trends:

The market for UV tapes is expanding gradually in Europe because of the growing focus on sustainability and advanced manufacturing in industries, such as automotive, aerospace, and healthcare. Germany, France, and the UK are adopting UV tapes for applications in semiconductor manufacturing, medical equipment assembly, and surface protection. Increasing investments in renewable energy and electronics manufacturing are further propelling the market growth.

Latin America UV Tapes Market Trends:

On account of the growing foreign investments, particularly in automotive and electronic sectors, Latin America is enjoying UV tapes market expansion. In Brazil, UV tapes are gaining traction among manufacturers as they improve production efficiency in industries like construction, where they are used for surface protection and bonding.

Middle East and Africa UV Tapes Market Trends:

The market for UV tapes in the Middle East and Africa region is distinguished by the thriving construction, automotive, and oil and gas industries. Countries like the UAE and Saudi Arabia are leveraging UV tapes for surface protection during infrastructure projects and industrial applications. The region’s rising focus on diversifying its economy is encouraging investments in the electronic and automotive sectors, offering lucrative growth opportunities to UV tape manufacturers.

Top Companies Leading in the UV Tapes Industry

Some of the leading UV tapes market companies include AI Technology Inc., Chase Corporation, Denka Company Limited, Furukawa Electric Co. Ltd., LINTEC Corporation, Loadpoint Ltd, Minitron Elektronik GmbH, Mitsui Chemicals, Nitto Denko Corporation, Sumitomo Bakelite Co., Ltd., Ultron Systems Inc., among many others. In February 2024, Nitto Denko and researchers at Kyushu University announced their collaboration and launched a UV-sensitive tape that can transfer two-dimensional (2D) materials like Graphene. This partnership aims to smoothen the integration of ultra-thin materials into a myriad of applications, ranging from electronics and aeronautics to construction and medical devices.

Global UV Tapes Market Segmentation Coverage

- On the basis of the product, the market has been categorized into polyolefin, polyvinyl chloride, polyethylene terephthalate, and others, wherein polyolefin represents the leading segment due to its superior properties like high tensile strength, excellent elasticity, and resistance to chemicals and temperature variations. These characteristics make it ideal for diverse industrial applications, including semiconductor manufacturing and automotive assembly. Additionally, polyolefin UV tapes are lightweight, cost-effective, and eco-friendly, which make them sustainable and efficient materials. Polyolefin UV tapes provide strong adhesion without leaving residue, making them highly preferred in delicate processes like electronics and wafer dicing.

- Based on the application, the market has been classified into wafer dicing, back grinding, and others, amongst which wafer dicing dominates the market owing to the critical role of UV tapes in the semiconductor manufacturing process. UV tapes are essential for securing wafers during cutting, protecting them from damage, and ensuring precision. Furthermore, UV tapes offer clean removal and minimal contamination, meeting the stringent quality standards of semiconductor production. Continuous advancements in microelectronics and the increasing adoption of UV tapes in high-tech manufacturing are supporting their market dominance in wafer dicing applications.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 537.5 Million |

| Market Forecast in 2033 | USD 1,014.2 Million |

| Market Growth Rate 2025-2033 | 8.26% |

| Units | Million USD |

| Segment Coverage | Product, Application, Region |

| Region Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | AI Technology Inc., Chase Corporation, Denka Company Limited, Furukawa Electric Co. Ltd., LINTEC Corporation, Loadpoint Ltd, Minitron Elektronik GmbH, Mitsui Chemicals, Nitto Denko Corporation, Sumitomo Bakelite Co. Ltd. and Ultron Systems Inc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

.webp)

.webp)