Global Superalloys Market Expected to Reach USD 10.0 Billion by 2033 - IMARC Group

Global Superalloys Market Statistics, Outlook and Regional Analysis 2025-2033

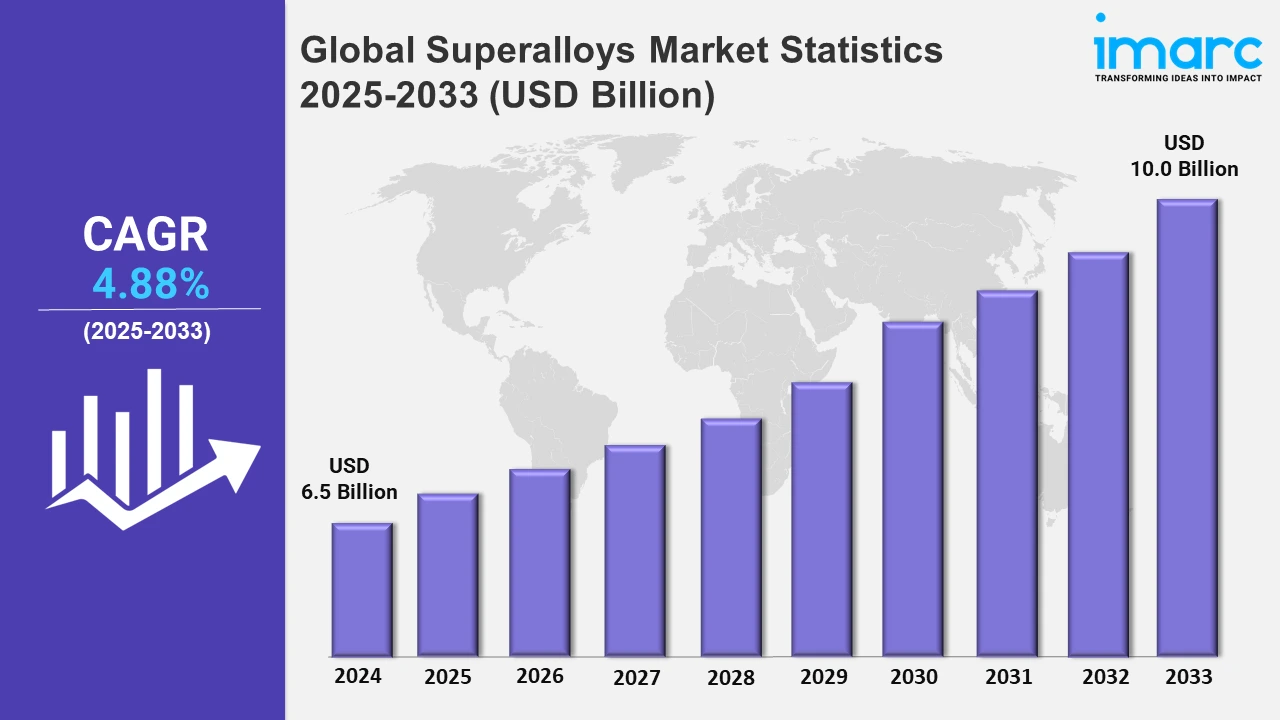

The global superalloys market size was valued at USD 6.5 Billion in 2024, and it is expected to reach USD 10.0 Billion by 2033, exhibiting a growth rate (CAGR) of 4.88% from 2025 to 2033.

To get more information on this market, Request Sample

The global superalloys market is witnessing steady growth, driven by increasing demand from aerospace, automotive, and energy sectors. In aerospace, the rising need for high-performance materials capable of withstanding extreme temperatures and pressures has boosted the adoption of superalloys in engine components. For instance, in May 2024, NASA licensed its GRX-810 superalloy to five US companies, allowing them to manufacture and sell this durable, high-temperature material for aviation, aerospace, and related supply chain applications. Additionally, the automotive industry is increasingly incorporating superalloys in turbochargers and exhaust valves to improve engine efficiency and durability. The power generation sector also relies on these materials for turbine blades and other critical components in gas and steam turbines, driven by the growing focus on energy efficiency and reliability.

Another emerging trend in the market highlights a shift toward lightweight and corrosion-resistant superalloys, enabling enhanced fuel efficiency and reduced emissions across industries. The rising adoption of additive manufacturing (3D printing) is further transforming the production of complex superalloy components, reducing lead times and material wastage. Technological advancements in alloy development, such as nickel-based superalloys with superior heat resistance, are opening new avenues for innovation. For instance, in November 2024, EOS introduced two nickel-based superalloy powders, for its PBF-LB machines, enhancing 3D printing applications in high-stress, high-temperature, and corrosion-resistant industrial environments. The increasing focus on renewable energy, particularly wind and solar power, is also driving demand for superalloys in energy storage systems and critical infrastructure.

Global Superalloys Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, North America accounted for the largest market share on account of robust aerospace demand, advanced manufacturing capabilities, and significant technological innovations.

North America Superalloys Market Trends:

North America leads the global superalloys market due to its advanced aerospace, defense, and power generation industries. The region benefits from strong technological innovation, robust R&D investments, and established manufacturing infrastructure. The presence of major aerospace companies and extensive demand for high-performance materials in jet engines, gas turbines, and space applications drive market growth. For instance, in November 2024, Norsk Titanium secured continued US Department of Defense funding to enhance its Rapid Plasma Deposition technology for producing high-strength, corrosion-resistant nickel superalloy components for defense and oil and gas industries. Additionally, rising adoption of additive manufacturing technologies enhances superalloy production efficiency. North America's focus on developing durable, high-temperature materials positions it as a key player in the global superalloys sector.

Asia-Pacific Superalloys Market Trends:

The Asia Pacific region is a fast-growing market with growing industrialization, rising aerospace and energy requirements, and diversifying manufacturing capacities. Higher expenditure on defense, generation of electricity, and automotive industry provides additional impetus to superalloy demand and manufacturing in the region.

Europe Superalloys Market Trends:

Europe is a prominent segment in the global superalloys market, owing to its strong aerospace, automotive, and energy industries. Increasing technological development, cost-efficient manufacturing processes, and the rising need for superalloys to be used in jet engines and gas turbines further cement Europe as a leading market.

Latin America Superalloys Market Trends:

Latin America is an emerging region in the global superalloys market due to rising investments in aerospace, energy, and industrial sectors. Increasing concern for efficient power generation and booming infrastructure projects are applying pressure on the utilization of superalloys across the region.

Middle East and Africa Superalloys Market Trends:

The Middle East and Africa are a potential market for superalloys, driven by expanding energy, aerospace, and industrial sectors. Growing interest in power generation business, investments in aviation and oil and industries, and establishing upstream projects require high-performance superalloys for the region’s rising industrial sector.

Top Companies Leading in the Superalloys Industry

Some of the leading superalloys market companies include Allegheny Technologies Inc, AMG Superalloys, Aperam S.A., Cannon-Muskegon Corporation, Carpenter Technology Corporation, Doncasters Group, Haynes International Inc, IHI Corporation, IMET Alloys, Mishra Dhatu Nigam Limited, Special Metals Corporation, Western Australian Specialty Alloys (Precision Castparts Corp.), among many others. In October 2024, Aperam S.A. strategically acquired Universal Stainless & Alloy Products, Inc., a prominent steel products company for crucial industrial and aerospace applications. This move highlights the company's expanding foothold across aerospace market.

Global Superalloys Market Segmentation Coverage

- On the basis of the base material, the market has been categorized into nickel-based, iron-based, and cobalt-based, wherein nickel-based represent the leading segment, owning to their high strength, ability to resist corrosion and high operating temperatures. Common in aerospace, energy, and industrial gas applications, their high-temperature tolerance ensures reliable performance in optimal applications, thereby sustaining demand across countries.

- Based on the application, the market is classified into aerospace (commercial and cargo, business, military and rotary), industrial gas turbine (electrical and mechanical), automotive, oil and gas, industrial, and others, amongst which aerospace dominates the market due to the need of high-performance materials in jet engines or turbine parts. The characteristics such as high strength, thermal stability, and high durability of superalloys are critical for aircraft power, reliability, and structural integrity to meet increasing commercial, military, and space needs globally.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 10.0 Billion |

| Market Growth Rate 2025-2033 | 4.88% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Base Materials Covered | Nickel-Based, Iron-Based, Cobalt-Based |

| Applications Covered |

|

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Allegheny Technologies Inc, AMG Superalloys, Aperam S.A., Cannon-Muskegon Corporation, Carpenter Technology Corporation, Doncasters Group, Haynes International Inc, IHI Corporation, IMET Alloys, Mishra Dhatu Nigam Limited, Special Metals Corporation, Western Australian Specialty Alloys (Precision Castparts Corp.), etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Superalloys Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)