Global Propylene Oxide Market Expected to Reach USD 33.1 Billion by 2033 - IMARC Group

Global Propylene Oxide Market Statistics, Outlook and Regional Analysis 2025-2033

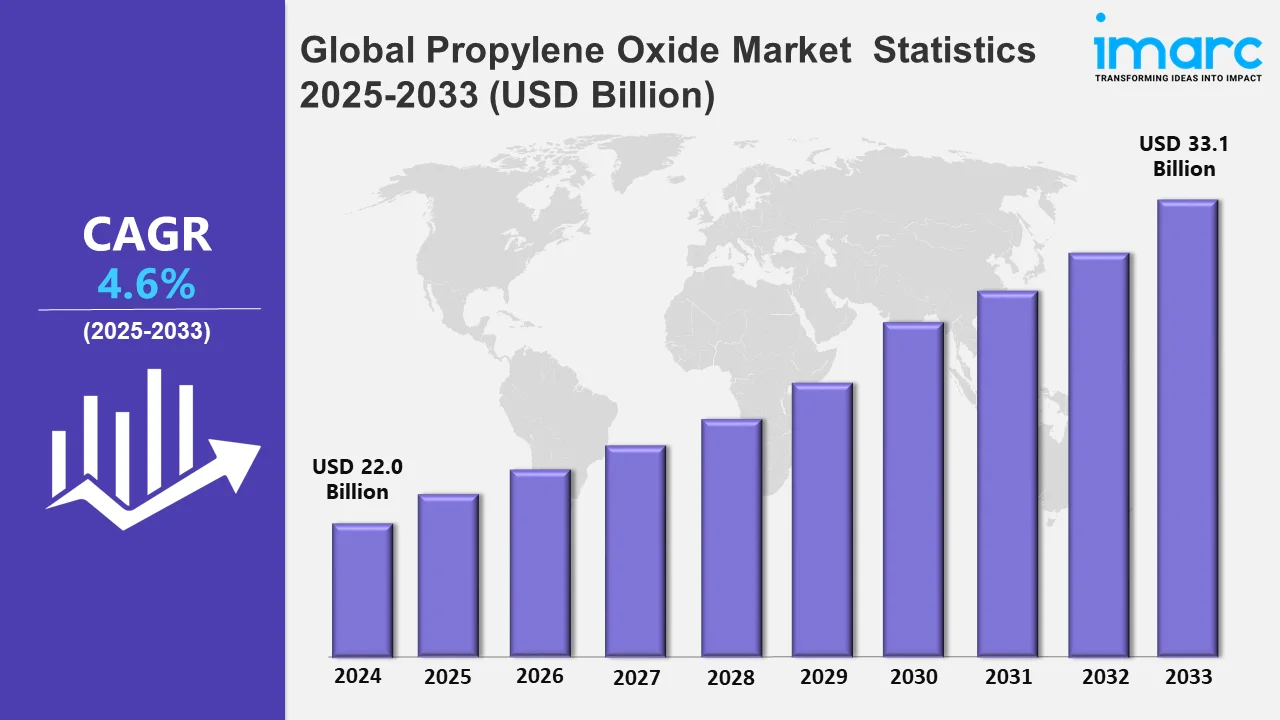

The global propylene oxide market size was valued at USD 22.0 Billion in 2024, and it is expected to reach USD 33.1 Billion by 2033, exhibiting a growth rate (CAGR) of 4.6% from 2025 to 2033.

To get more information on this market, Request Sample

The global propylene oxide market is witnessing significant growth, driven by rising demand for polyurethane products across industries such as automotive, construction, and furniture. Polyurethane's versatility in creating lightweight, durable, and energy-efficient materials makes it a preferred choice for applications like insulation, adhesives, and flexible foams. Moreover, the rising automotive production, coupled with heavy utilization of propylene oxide-derived polyether polyols for the manufacturing of lightweight components that can efficiently improve fuel efficiency and meet stringent emission standards, is driving the market expansion. For instance, as per industry reports, in FY24, India recorded a total production of 28,434,742 units, encompassing passenger vehicles, commercial vehicles, two-wheelers, three-wheelers, and quadricycles. Additionally, the construction industry’s growing emphasis on energy-efficient buildings is boosting demand for insulation materials, further fueling the market for propylene oxide.

Innovations in production technologies are another key driver, with advancements such as the development of sustainable manufacturing methods and processes that reduce by-product generation gaining traction. The styrene monomer and hydrogen peroxide-based processes are becoming increasingly popular due to their cost efficiency and environmental compliance. Furthermore, the market benefits from heightened regulatory requirements for high-quality and eco-friendly materials, which propel the adoption of cleaner production techniques. Rising consumer awareness about sustainability and the shift toward green building materials are also encouraging manufacturers to invest in eco-friendly propylene oxide production. For instance, according to IMARC Group, green building materials market is anticipated to reach USD 739.9 Billion in 2033, highlighting growing need for such materials, which, in turn, will positively influence the global propylene oxide market.

Global Propylene Oxide Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific accounted for the largest market share due to rapid industrialization, growing end-use industries, and increased demand for polyurethane applications.

Asia-Pacific Propylene Oxide Market Trends:

Asia Pacific has emerged as a leading regional market for propylene oxide mainly because of its exponentially proliferating industrial base, especially in countries such as Japan, China, and India. The region's robust requirement for polyurethane products in key sectors, including furniture, automotive, and construction bolsters substantial utilization of propylene oxide. In addition, high-volume production plants and cost-effective manufacturing methodologies in the region aid its leading position. The magnifying infrastructure development and construction activities further fuel requirement for polyether polyols and related applications, fortifying Asia Pacific’s domination in the global market. Moreover, amplifying urbanization and notable economic growth also facilitate sustained regional demand. For instance, according to the UNICEF, the rapid urbanization in Asia is projected to result in nearly 55% of the region's vast population living in cities by 2030, reflecting the significant pace of growth in urban areas across the region.

North America Propylene Oxide Market Trends:

North America is one of the crucial players in the global propylene oxide market, chiefly propelled by the magnified need from the critical sectors, such as construction and automotive. Strict environmental policies and leading-edge manufacturing processes have notably incentivized the utilization of sustainable production techniques, boosting regional expansion and solidifying the supply chain for polyurethane-based applications.

Europe Propylene Oxide Market Trends:

Europe’s propylene oxide market heavily profits from its well-established construction and automotive industries, combined with a robust emphasis on advancements and sustainability. The region’s amplifying focus on energy-saving building solutions and lightweight materials for vehicle production significantly boosts need for polyether polyols, establishing Europe as a critical market for propylene oxide utilization.

Latin America Propylene Oxide Market Trends:

Latin America’s accelerating growth in automotive and construction sectors is posing as a key factor for the significant growth of its propylene oxide industry. Moreover, heightening infrastructure development initiatives and urbanization, especially in countries like Mexico and Brazil, support the fueling requirement for polyurethane products, offering opportunities for regional producers to proliferate manufacturing abilities and address the transforming market demands.

Middle East and Africa Propylene Oxide Market Trends:

The MEA propylene oxide market is driven by growing investments in construction and infrastructure projects. The region's focus on energy-efficient building materials and expanding industrial applications enhances demand for polyether polyols. Additionally, strategic partnerships and localized manufacturing initiatives strengthen the supply chain, supporting market growth in this region.

Top Companies Leading in the Propylene Oxide Industry

Some of the leading propylene oxide market companies include AGC Chemicals Americas Inc., Air Liquide S.A., BASF SE, Dow Inc., Eastman Chemical Company, Huntsman International LLC, Ineos Chemicals Company, LyondellBasell Industries Holdings B.V., Mitsui Chemicals, Repsol S.A., Royal Dutch Shell PLC, Saudi Arabia Basic Industries Corporation (Saudi Aramco), SK Chemicals Co. Ltd., Sumitomo Chemical Co. Ltd., Tokuyama Corporation., among many others. In May 2024, Dow announced the commencement of operations for its expanded propylene glycol (PG) production at its integrated facility in Thailand. This strategic, cost-efficient investment boosts PG capacity by 80,000 tons annually, raising total production to 250,000 tons per year, positioning the Map Ta Phut site as Asia Pacific's largest PG manufacturing facility. The site’s back-integration ensures a competitive and stable supply of essential raw materials, including propylene oxide.

Global Propylene Oxide Market Segmentation Coverage

- On the basis of the production process, the market has been categorized into chlorohydrin process (CHPO), styrene monomer process, hydrogen peroxide process, TBA co-product process, and cumene-based process, wherein styrene monomer process represents the leading segment. This domination is attributed to its efficiency in yielding high-quality output and reduced by-product generation. This method integrates seamlessly with existing styrene production facilities, optimizing operational costs and ensuring a reliable supply for downstream applications, making it a preferred choice for manufacturers globally.

- Based on the application, the market is classified into polyether polyols, propylene glycols, propylene glycol ethers (PGE), polyalkylene glycols, and others, amongst which polyether polyols dominates the market.This is driven by their extensive use in manufacturing flexible and rigid polyurethane foams. Furthermore, these foams find applications in diverse industries, including automotive, construction, and furniture, where durability and thermal insulation are critical, fueling consistent demand for polyether polyols globally.

- On the basis of the end use industry, the market has been divided into automotive, construction, chemicals and pharmaceuticals, packaging, textile and furnishing, and others. Among these, automotive accounts for the majority of the market share. This industry leverages its extensive use in producing lightweight polyurethane materials. These materials enhance fuel efficiency and vehicle performance while meeting stringent environmental standards. In addition, with rising vehicle production and increasing demand for sustainability, the automotive industry's reliance on propylene oxide continues to grow.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 22.0 Billion |

| Market Forecast in 2033 | USD 33.1 Billion |

| Market Growth Rate 2025-2033 | 4.6% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Production Processes Covered | Chlorohydrin Process (CHPO), Styrene Monomer Process, Hydrogen Peroxide Process, TBA Co-Product Process, Cumene-based Process |

| Applications Covered | Polyether Polyols, Propylene Glycols, Propylene Glycol Ethers (PGE), Polyalkylene Glycols, Others |

| End Use Industries Covered | Automotive, Construction, Chemicals and Pharmaceuticals, Packaging, Textile and Furnishing, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | AGC Chemicals Americas Inc., Air Liquide S.A., BASF SE, Dow Inc., Eastman Chemical Company, Huntsman International LLC, Ineos Chemicals Company, LyondellBasell Industries Holdings B.V., Mitsui Chemicals, Repsol S.A., Royal Dutch Shell PLC, Saudi Arabia Basic Industries Corporation (Saudi Aramco), SK Chemicals Co. Ltd., Sumitomo Chemical Co. Ltd., Tokuyama Corporation., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Propylene Oxide Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)