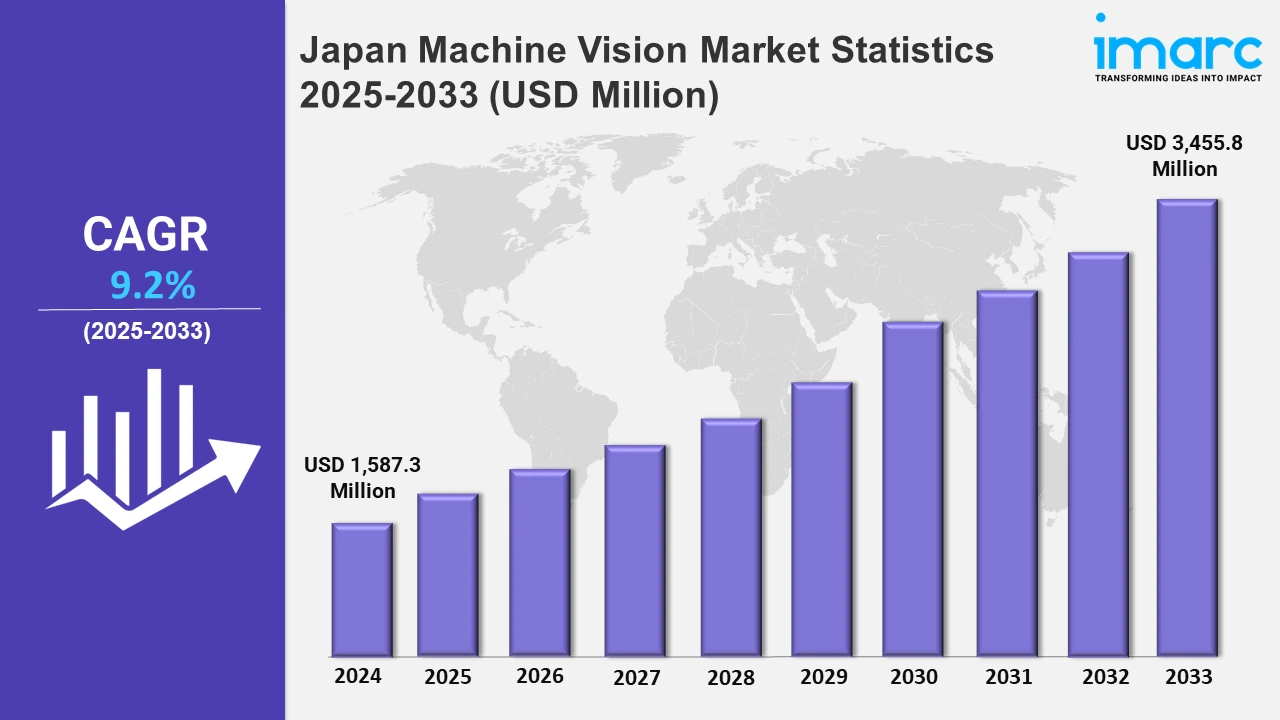

Japan Machine Vision Market Expected to Reach USD 3,455.8 Million by 2033 - IMARC Group

Japan Machine Vision Market Statistics, Outlook and Regional Analysis 2025-2033

The Japan machine vision market size was valued at USD 1,587.3 Million in 2024, and it is expected to reach USD 3,455.8 Million by 2033, exhibiting a growth rate (CAGR) of 9.2% from 2025 to 2033.

To get more information on this market, Request Sample

The growing manufacturing sector is significantly driving the expansion of the machine vision market across the country. Moreover, as industries increasingly adopt automation and precision technologies to enhance productivity, machine vision systems are becoming essential in Japan. These systems are used for quality control, inspection, and real-time monitoring. Besides this, the elevating focus of key authorities in Japan on automotive, electronics, and industrial machinery manufacturing further accelerates the demand for advanced machine vision solutions.

Additionally, the country faces a labor shortage due to its aging population, which drives the adoption of automation technologies like machine vision. Japan is anticipated to experience a labor shortage comparable to more than 3 million workers by 2035. By reducing the need for manual inspection and assembly, machine vision systems help mitigate the impact of labor shortages, enabling companies to maintain high levels of production without relying heavily on human labor. Besides this, the country is a leader in electronics and semiconductor manufacturing, which requires high-precision and automated inspection processes. Machine vision sycontrol andsential for inspecting tiny components, ensuring quality control, and facilitating the complex assembly processes in these industries. As Japan’s consumer electronics and semiconductor sectors continue to grow, the demand for machine vision systems is expected to fuel the market in the coming years.

Japan Machine Vision Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region. The rising labor shortage, along with the expanding manufacturing sector, is driving the growth of the market across various regions in the country.

Kanto Region Machine Vision Market Trends:

The Kanto region, including Tokyo, is a home for innovations. Moreover, companies like Fanuc and Yaskawa utilize machine vision for precision in robotics. Also, automated factories in Kawasaki use novel systems for pick-and-place applications, ensuring minimal errors. Besides this, the growth of the region is attributed to the surging focus on industrial automation.

Kansai/Kinki Region Machine Vision Market Trends:

The Kansai region, home to Osaka and Kyoto, focuses on AI-driven machine vision in the healthcare sector. Additionally, companies like Omron in Kyoto develop systems for quality control in medical device manufacturing. Besides this, in Osaka, AI-powered retail checkout systems are becoming more common, further escalating the market growth.

Central/Chubu Region Machine Vision Market Trends:

The surging automotive production in the Central/Chubu region, including Nagoya, is one of the key factors propelling the market growth. In addition, machine vision systems are crucial to automobile assembly lines, allowing for high-precision activities such as welding and painting. Besides this, automated inspection lines in Aichi Prefecture use machine vision to ensure defect-free output.

Kyushu-Okinawa Region Machine Vision Market Trends:

The growing semiconductor manufacturing in Fukuoka is driving the market growth in the Kyushu-Okinawa region. Additionally, machine vision systems are extensively used for wafer inspection and defect detection in semiconductor manufacturing. Apart from this, various companies like Tokyo Electron integrate AI into vision technologies, further bolstering the growth of the market.

Tohoku Region Machine Vision Market Trends:

The Tohoku region specializes in renewable energy technologies, using machine vision for advancements. Moreover, vision-based systems in the agriculture industry enhance crop monitoring and harvesting, further supporting sustainable farming. Besides this, Fukushima shows how machine vision improves productivity and environmental efficiency, thereby escalating the market demand.

Chugoku Region Machine Vision Market Trends:

The Chugoku region, which includes Hiroshima, focuses on machine vision in agriculture. Moreover, vision-enabled robots in Okayama Prefecture automate fruit picking, lowering labor requirements. Besides this, the region's efforts to alleviate labor shortages in agriculture while increasing productivity are also contributing to the market growth.

Hokkaido Region Machine Vision Market Trends:

Hokkaido, an agricultural heartland in Japan, is a leader in using machine vision for large-scale precision farming. Vision systems are utilized in drones and tractors to analyze crop health and optimize yield. Moreover, farms in Sapporo use automated machinery to harvest potatoes. This reflects the region's focus on sustainable farming practices, which are critical for maintaining its enormous farmlands.

Shikoku Region Machine Vision Market Trends:

The demand for machine vision in the Shikoku region is attributed to its growing chemical and pharmaceutical industries, especially in Tokushima and Ehime. Moreover, vision systems help in quality assurance in manufacturing, including inspecting tablet coatings. Besides this, the surging focus on precision-driven production fosters the adoption of advanced vision technologies, including AI-powered defect detection.

Top Companies Leading in the Japan Machine Vision Industry

The competitive landscape of the Japan machine vision market is marked by prominent organizations which dominate the region. To remain competitive, companies in the market are focusing on innovation, product customization, and cost-effective solutions to meet the needs of their customers.

Japan Machine Vision Market Segmentation Coverage

- On the basis of the product, the market is bifurcated into vision systems, cameras, and others. Vision systems are the backbone of machine vision technology as they integrate cameras, processors, and software to analyze visual data. Moreover, cameras in machine vision act as the primary image acquisition tools, capturing high-quality images or video for analysis.

- Based on the component, the market is divided into hardware and software. Hardware in machine vision includes the physical components necessary for image acquisition and processing. Key elements are cameras, lighting systems, lenses, frame grabbers, and processors. While software interprets visual data captured by hardware, providing the intelligence to automate tasks.

- On the basis of the application, the market has been bifurcated into positioning, identification, verification, measurement, flaw detection, and others. Positioning in machine vision refers to identifying the exact location and orientation of objects in a given workspace. This capability guides robotic arms and other automated systems. Moreover, identification includes recognizing and classifying objects, patterns, or codes within an image. Machine vision systems excel in reading barcodes, QR codes, or alphanumeric text. Besides this, measurement uses machine vision to determine dimensions, distances, or angles within an image.

- Based on the industry, the market has been bifurcated into electronics and semiconductor, automotive, medical and pharmaceutical, food, packaging and printing, security and surveillance, intelligent traffic system, and others. Machine vision aids in ensuring precision and quality in manufacturing processes. Moreover, in the automotive sector, machine vision ensures safety and efficiency. Besides this, medical device and pharmaceutical manufacturing utilizes machine vision for regulatory compliance. Furthermore, in the food industry, it is used for sorting and grading fruits, vegetables, and grains based on size, color, and defects.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 1,587.3 Million |

| Market Forecast in 2033 | USD 3,455.8 Million |

| Market Growth Rate 2025-2033 | 9.2% |

| Units | Million USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Products Covered | Vision Systems, Cameras, Others |

| Components Covered | Hardware, Software |

| Applications Covered | Positioning, Identification, Verification, Measurement, Flaw Detection, Others |

| Industries Covered | Electronics and Semiconductor, Automotive, Medical and Pharmaceutical, Food, Packaging and Printing, Security and Surveillance, Intelligent Traffic System, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Machine Vision Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

.webp)

.webp)