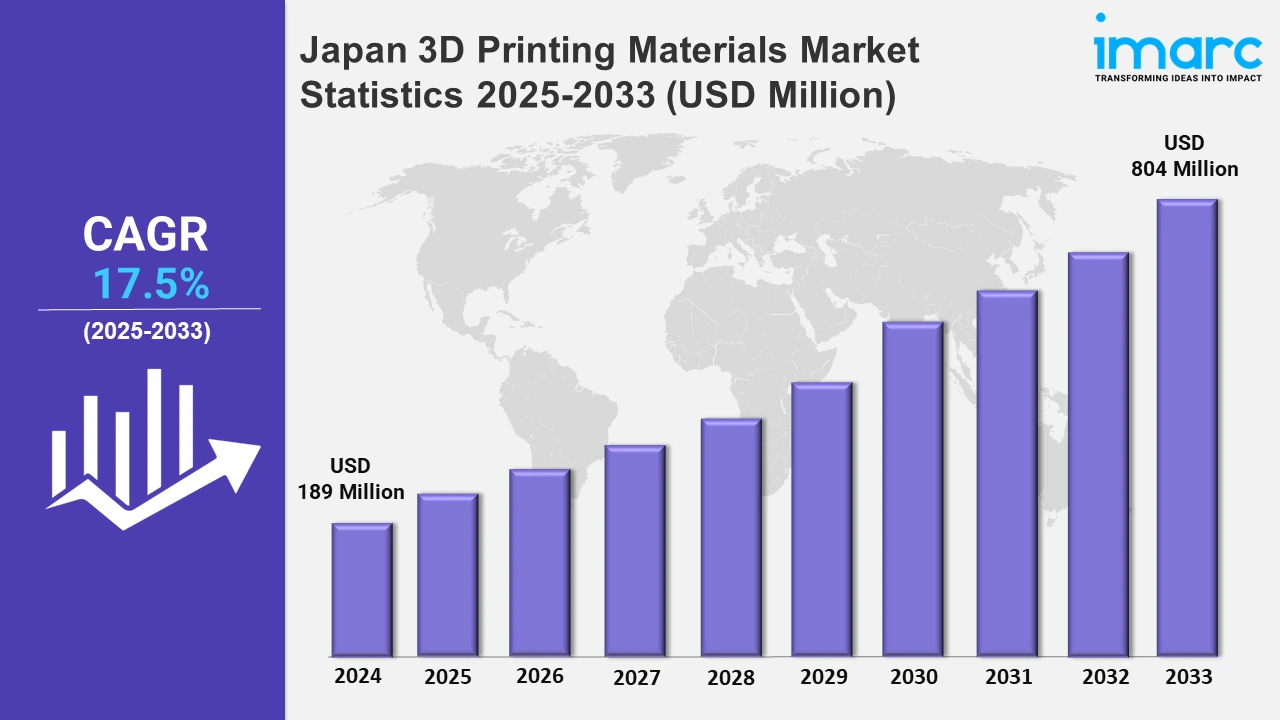

Japan 3D Printing Materials Market Expected to Reach USD 804 Million by 2033 - IMARC Group

Japan 3D Printing Materials Market Statistics, Outlook and Regional Analysis 2025-2033

The Japan 3D printing materials market size was valued at USD 189 Million in 2024, and it is expected to reach USD 804 Million by 2033, exhibiting a growth rate (CAGR) of 17.5% from 2025 to 2033.

To get more information on this market, Request Sample

The increasing use of advanced manufacturing methods is boosting the demand for 3D printing materials in Japan. The ability to create high-performance, customizable products with enhanced precision and reduced production costs is fueling industry’s growth. This innovation meets consumer demands for superior functionality while enabling manufacturers to achieve greater efficiency and expand design possibilities. For instance, in December 2023, Designer, a brand based in Japan, introduced a 3D-printed titanium golf club head. This is made using Farsoon Technologies’ metal 3D printer. Moreover, the use of this printer reduces the overall cost of manufacturing, further escalating the demand for optimal materials.

Additionally, the rising inclination towards the adoption of sustainable materials is shaping the 3D printing landscape in Japan, focusing on eco-friendly and high-performance solutions. By integrating recycled polymers and cellulose nanofibers, manufacturers are creating innovative materials that reduce environmental impact while enhancing strength and formability. These advancements align with growing demands for sustainability in industries like automotive and aeronautics, where durable and lightweight materials are essential. Partnerships and investments in green technologies are driving the development of compounds that combine functionality with environmental responsibility, supporting a more sustainable manufacturing future. For example, a technology firm based in Japan, Asahi Kasei, teamed up with Aquafil to create an innovative 3D printing material that merges Aquafil's recycled PA6 with Asahi Kasei's cellulose nanofiber. The compound offers enhanced strength and formability, ideal for automotive and aerospace uses, supported by ITOCHU. Besides this, 3D printing materials are expanding the medical industry by enabling the manufacturing of customized medical devices, implants, and even organs. This has increased the demand for biocompatible and sterilizable 3D printing materials.

Japan 3D Printing Materials Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/ Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region. The support for advanced manufacturing technologies by regulatory authorities and research initiatives fosters a positive environment for market growth.

Kanto Region 3D Printing Materials Market Trends:

The growing demand for consumer electronics across the Kanto region is driving the adoption of 3D printing. Various companies in Tokyo are integrating advanced materials to improve product design. Also, the automotive manufacturers are utilizing high-strength metals for production, thereby further propelling the market expansion in the Kanto region.

Kansai/Kinki Region 3D Printing Materials Market Trends:

The Kansai/Kinki region focuses on textile and ceramics manufacturing. The adoption of 3D printing materials allows for the creation of detailed designs in textiles. Apart from this, it also reduces production time and material waste. Various manufacturers are experimenting with ceramics to produce customizable products, further driving the market expansion in the Kansai/Kinki region.

Central/Chubu Region 3D Printing Materials Market Trends:

In the Central/Chubu region, the automotive industry is adopting 3D printing materials to produce lightweight components. The rising integration of metal alloys in this advanced process across the region improves the overall performance of the vehicles. For example, various companies in Nagoya are innovating 3D printing to produce metal parts for automobiles.

Kyushu-Okinawa Region 3D Printing Materials Market Trends:

The increasing food production in the Kyushu-Okinawa region is driving the adoption of 3D printing materials. Various companies in Fukuoka are adopting optimal materials that are safe to produce edible products. These factors are further accelerating the demand for 3D printing materials in the Kyushu-Okinawa region.

Tohoku Region 3D Printing Materials Market Trends:

The escalating demand for the development of sustainable materials in the Tohoku region is driving the growth of the market. Various companies in Sendai are creating eco-friendly alternatives, like bio-plastics for 3D printing. Apart from this, universities in the Tohoku region are also creating eco-friendly printing filaments, which is further supporting the market growth.

Chugoku Region 3D Printing Materials Market Trends:

The paper industry in the Chugoku region is utilizing 3D printing materials, thereby expanding the market. Various manufacturers across the area are adopting 3D printing materials to create innovative packaging solutions, thereby contributing to the market growth in the Chugoku region.

Hokkaido Region 3D Printing Materials Market Trends:

In Hokkaido, there is a growing trend of utilizing 3D materials in the agriculture sector. The adoption of this modern technique allows the development of specialized tools. Moreover, the adoption of durable 3D printing materials improves the efficiency and life of farming equipment. Besides this, Hokkaido University is also researching how 3D-printed structures can help in precision farming.

Shikoku Region 3D Printing Materials Market Trends:

The expanding marine industry is driving the market growth in the Shikoku region. Various companies across the area are focusing on printing lightweight materials like polymers. Also, Kochi University of Technology, Japan, is involved in research using 3D printing to produce ship hull parts, thereby accelerating the growth of the market.

Top Companies Leading in the Japan 3D Printing Materials Industry

The market research report encompasses detailed profiles of all businesses in the country. In December 2023, Designer, a brand based in Japan, introduced a 3D-printed titanium golf club head. This is made using Farsoon Technologies’ metal-3D printer. Moreover, the use of this printer reduced the overall cost of manufacturing. Furthermore, in December 2024, a team of researchers at Tohoku University unveiled a multi-material 3D printing technique by adopting L-PBF technology to create durable but lightweight components of automobiles.

Japan 3D Printing Materials Market Segmentation Coverage

- On the basis of the type, the market has been bifurcated into polymers (acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), photopolymers, nylon, and others), metals (steel, titanium, aluminum, and others), ceramic (silica sand, glass, gypsum, and others), and others. Polymers are extensively adopted in 3D printing due to ease of use. Moreover, metals have high strength, which makes them widely suitable for the aerospace sector. Besides this, ceramics are known for their hardness and resistance to heat. They are used in casting detailed models.

- Based on the form, the market has been bifurcated into powder, filament, and liquid. Powders are often metals, polymers, or ceramics and are fused by a laser to create a solid object. Moreover, liquid based 3D printing materials are used in technologies like DLP.

- On the basis of the end user, the market has been bifurcated into consumer products, aerospace and defense, automotive, healthcare, education and research, and others. Companies are utilizing 3D printing to manufacture consumer products as it reduces the production cost. In aerospace and defense, it is adopted to produce lightweight parts.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 189 Million |

| Market Forecast in 2033 | USD 804 Million |

| Market Growth Rate 2025-2033 | 17.5% |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered |

|

| Forms Covered | Powder, Filament, Liquid |

| End Users Covered | Consumer Products, Aerospace and Defense, Automotive, Healthcare, Education and Research, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on 3D Printing Materials Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)