Japan 3D Printing Market Expected to Reach USD 8.2 Billion by 2033 - IMARC Group

Japan 3D Printing Market Statistics, Outlook and Regional Analysis 2025-2033

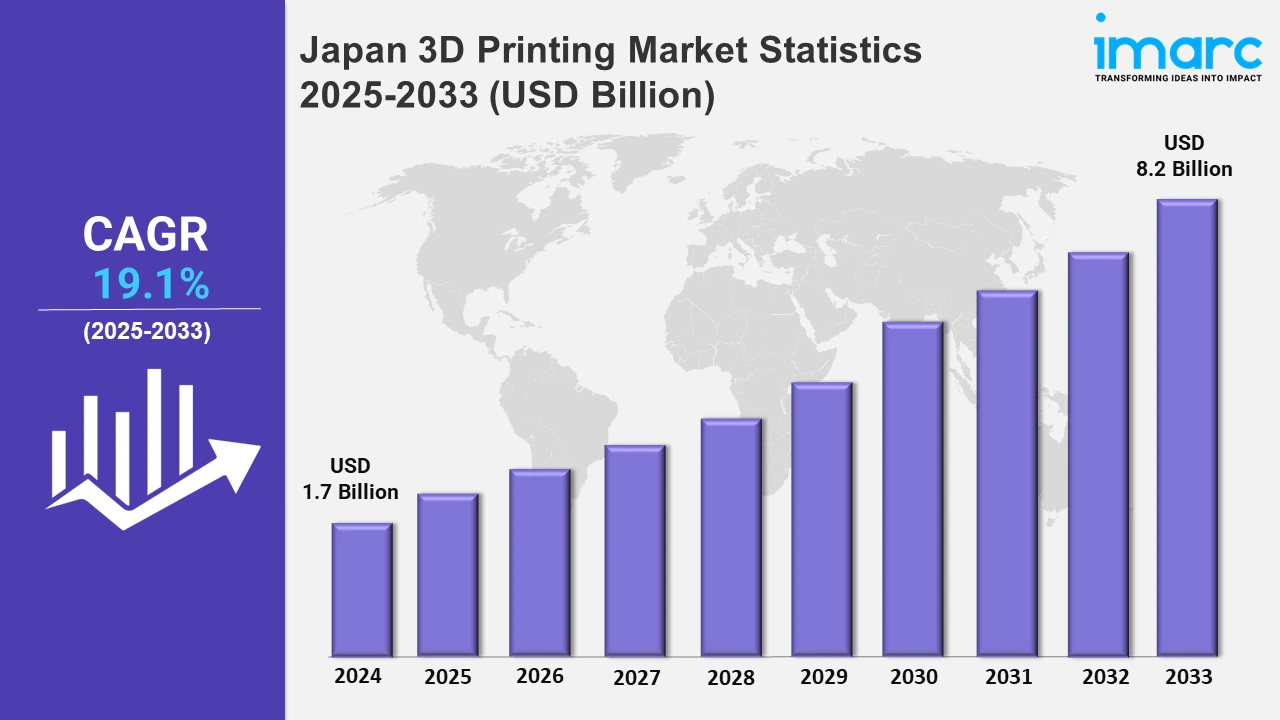

The Japan 3D printing market size was valued at USD 1.7 Billion in 2024, and it is expected to reach USD 8.2 Billion by 2033, exhibiting a growth rate (CAGR) of 19.1% from 2025 to 2033.

To get more information on this market, Request Sample

The increasing corporate expenditures in innovative additive manufacturing technology are critical for producing lightweight, robust, and intricate components, which is propelling the market in Japan. For example, in September 2024, 3DEO received USD 3.5 Million from Japan's Mizuho Bank through the Transition Investment Facility. This grant helped the company to integrate intelligent layering and design for additive manufacturing, with a focus on innovation and sustainable production. These developments highlight the inclination among key players towards precise engineering and environmentally sustainable methods, which is boosting the requirement of metal 3D printing.

Additionally, 3D printing is rapidly advancing in Japan’s healthcare industry, especially for personalized prosthetics, dental implants, and surgical tools. In May 2024, UNIDO partnered with the Government of Japan to launch a project in Ukraine focusing on 3D-printed prosthetics. The program equipped facilities with advanced 3D printers and provided prosthetics to people affected by the conflict. It also aimed to improve mobility, create long-term job opportunities, and support Ukraine’s economic recovery. This technology’s ability to create patient-specific solutions also enhances treatment efficiency. Besides this, manufacturers in Japan are prioritizing the use of recyclable materials, reflecting the country's dedication to minimize environmental effects. For example, in October 2024, Asahi Kasei, a technology company in Japan, collaborated with Aquafil S.p.A. to create a unique 3D printing material. This high-strength compound is used for aerospace and automotive applications. Such advances in bio-based and biodegradable materials are gaining traction, enabling greener options for enterprises seeking to fulfill sustainability targets.

Japan 3D Printing Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kinki region, Central/ Chubu region, Kyushu/Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region. The rising government support through research collaborations, funding, and subsidies is escalating the market growth.

Kanto Region 3D Printing Market Trends:

The Kanto region is an industrial hub driving the 3D printing market. With a rising number of technology companies, the region fosters innovation in additive manufacturing. Moreover, universities in Tokyo also support material advancements, which is further acting as another growth-inducing factor.

Kinki Region 3D Printing Market Trends:

The strong commercial sector in the Kinki region is one of the key factors driving the growth of the market. The area is well known for its robust manufacturing base, thereby further leading to a surge in the demand for automobiles. Moreover, growing collaborations in Osaka are also fostering innovation, which is accelerating the adoption of 3D printing in the Kinki region.

Central/Chubu Region 3D Printing Market Trends:

The expanding automotive and aerospace industries in the Central region, including Nagoya, are acting as one of the major growth-inducing factors. The region's strong manufacturing base and high technical skills enable it to develop additive manufacturing methods continuously. Chubu's industrial areas bring together businesses and technology providers, thereby supporting innovation in materials and manufacturing techniques.

Kyushu-Okinawa Region 3D Printing Market Trends:

The rising eco-tourism efforts across the region are driving the demand for 3D printing to promote the development of sustainable buildings. Various companies are exploring concrete-based 3D printing to build affordable houses. Kyushu University is researching eco-friendly 3D printing materials to meet construction needs.

Tohoku Region 3D Printing Market Trends:

There has been a significant advancement in the medical sector across the Tohoku region. The region uses Japan’s 3D printing to produce medical devices like surgical models. Also, researchers at Tohoku University have developed 3D-printed bone implants to reduce patient recovery time.

Chugoku Region 3D Printing Market Trends:

Chugoku region has a growing automotive sector, which is contributing significantly to the market growth. Various companies in this region are adopting 3D printing to reduce production times for automotive manufacturing. Moreover, the rising number of collaborations between industries and research institutions is also stimulating market demand.

Hokkaido Region 3D Printing Market Trends:

Hokkaido is focusing on 3D printing owing to the strong food-processing industries. Various companies across Hokkaido use 3D food printers to make unique and customized dishes. Besides this, various events like the Sapporo Snow Festival even feature 3D-printed food sculptures, thereby combining modern technology with local culture.

Shikoku Region 3D Printing Market Trends:

The mountains in the Shikoku region propels the need for 3D printing for drone manufacturing. Drones are used for maintaining infrastructure in remote areas. Various universities across the region use 3D printing to make lightweight, durable parts for drones. These innovations help improve access in regions with few roads, solving unique challenges.

Top Companies Leading in the Japan 3D Printing Industry

The competitive landscape of the Japan 3D printing market is marked by prominent organizations which dominate the country. For example, in October 2024, Obayashi Corporation launched Japan's first 3D-printed earthquake-resistant building, the 3dpod. The construction meets Japan's high earthquake criteria without typical reinforcements. All above-ground structural components of the 3dpod are printed using modern 3D technology, which also includes insulation and radiant systems.

Japan 3D Printing Market Segmentation Coverage

- On the basis of the technology, the market has been bifurcated into stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others. Stereolithography is generally used in the medical sector due to its accuracy and smooth surface finishes. In contrast, fused deposition modeling is widely adopted in consumer electronics. It includes extruding melted thermoplastic material layer by layer to fabricate functional parts. Besides this, electron beam melting plays an important role in crafting high-quality metal components for the aerospace industry.

- Based on the process, the market has been bifurcated into binder jetting, directed energy deposition, material extrusion, material jetting, power bed fusion, sheet lamination, and vat photopolymerization. Binder jetting is becoming popular for making metal and ceramic parts with precision and efficiency. This process uses a binder to bond materials to create lightweight and affordable components. Moreover, directed energy deposition is widely adopted in the aerospace and automotive industries in Japan to create and repair high-performance metal parts.

- On the basis of the material, the market has been bifurcated into photopolymers, plastics, metals and ceramics, and others. Photopolymers are widely used in healthcare to create detailed and accurate prototypes. These materials harden under UV light, making them perfect for applications like dental devices. Additionally, plastics are cost-efficient. Various companies across Japan are innovating recyclable plastics.

- Based on the offering, the market has been bifurcated into printer, material, software, and service. The 3D printer converts the CAD file into a 3D model by depositing material layer by layer. Moreover, the material used in this printing technology can include plastics, metals, or ceramics. Besides this, software is one of the most important components as it is used to design a 3d model.

- On the basis of the application, the market has been bifurcated into prototyping, tooling, and functional part manufacturing. Prototyping offers the cost-effective development of products across various industries. Moreover, the tooling allows for the efficient production of custom molds, jigs, and fixtures. Besides this, functional part manufacturing is a growing application in Japan’s 3D printing market, addressing the need for end-use parts in industries like healthcare, aerospace, and automotive.

- Based on the end user, the market has been bifurcated into consumer products, machinery, healthcare, aerospace, automobile, and others. The consumer products in the market leverages additive manufacturing for customized, innovative, and cost-efficient production. Moreover, the machinery utilizes 3D printing to enhance production efficiency and reduce lead times for complex components.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 1.7 Billion |

| Market Forecast in 2033 | USD 8.2 Billion |

| Market Growth Rate 2025-2033 | 19.1% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Power Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramics, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Regions Covered | Kanto Region, Kinki Region, Central/ Chubu Region, Kyushu/Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on 3D Printing Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

.webp)

.webp)