How to Set Up a Manufacturing Plant in India: A Comprehensive Guide

.webp)

India is becoming a popular location for foreign manufacturers because of its quickly expanding economy, affordable labour costs, and consistent government support. For businesses looking to establish manufacturing facilities in the nation, the Government's "Make in India" incentive program offers an alluring alternative. This guide will assist in comprehending the crucial requirements for setting up a manufacturing facility in India.

Introduction: Why India is the Ideal Destination for Manufacturing

India as a Global Manufacturing Hub

Global manufacturers are increasingly finding India as an attractive destination. With its strategic location, large consumer market, and improving infrastructure, the country is an attractive alternative for companies wishing to relocate their manufacturing base. Also, with a focus on sustainability and green manufacturing, India is in sync with global trends and would be the right choice for the future.

Key Benefits of Setting Up a Plant in India

- Government Initiatives: Programs like "Make in India," "Production Linked Incentive (PLI) Scheme," and "Atmanirbhar Bharat" offer significant incentives for manufacturers.

- Cost Efficiency: Lower labour costs, affordable raw materials, and tax benefits make India a cost-effective manufacturing base.

- Sustainability Focus: The government is promoting green manufacturing practices, including renewable energy adoption and waste reduction.

- Industry 4.0 Adoption: Smart factories, IoT, and automation are gaining traction, enabling manufacturers to improve efficiency and productivity.

Prominent Manufacturing Sectors in India

India’s manufacturing landscape is diverse, with several sectors showing remarkable growth and global importance. Here are some key sectors and notable projects:

- Automotive: India's potential in the EV sector is highlighted by Tesla's plan to build a manufacturing plant there. With companies like Tata Motors, Mahindra, and Maruti Suzuki at the vanguard, India has emerged as a hub for the production of automobiles.

- Electronics: Apple’s enhancement of iPhone production via Foxconn and Wistron highlights India’s increasing importance in electronics manufacturing. The government’s Production Linked Incentive (PLI) program has additionally strengthened this sector.

- Pharmaceuticals: India holds the title of the world's biggest provider of generic medications, with firms such as Sun Pharma and Dr. Reddy's at the forefront. The industry is also a significant exporter of vaccines and APIs (Active Pharmaceutical Ingredients).

- Textiles: The textiles industry is experiencing a rise in demand for sustainable and environment-friendly fabrics. India stands as a worldwide leader in the production and export of cotton.

- Renewable Energy: India stands as a world leader in the production of solar panels, propelled by companies such as Adani Solar and Tata Power Solar that are fostering innovation. The nation is additionally concentrating on wind power and battery production.

- Aerospace and Defence: India's aerospace and defence industry is swiftly expanding, supported by government programs such as Make in India and Atmanirbhar Bharat. The nation is prioritizing the decrease of reliance on imports while enhancing local production of defence gear, aircraft, and aerospace technology.

Steps to Set Up a Manufacturing Plant in India

Setting up a manufacturing plant in India involves several critical steps. Here’s a roadmap to guide you:

Step 1: Identify the Industry and Product/Service

- Conduct market research to identify the right industry and product/service for your plant.

- Analyse demand, competition, and growth potential.

Step 2: Choose the Right Location

- Consider factors like proximity to raw materials, labour availability, infrastructure, and government incentives.

- Special Economic Zones (SEZs) and industrial corridors offer additional benefits.

Step 3: Legal Compliances and Registrations

- Register your business entity (LLP, Pvt. Ltd., etc.).

- Obtain necessary licenses and permits (factory license, GST registration, environmental clearances, etc.).

Step 4: Workforce and Supply Chain Management

- Hire skilled labour and train them as per your requirements.

- Establish a robust supply chain network for raw materials and distribution.

Step 5: Understand Government Incentives and Schemes

- Leverage schemes like PLI, FAME (for EVs), and state-specific incentives.

- Consult experts to maximize benefits.

Step 6: Infrastructure and Technology Setup

- Invest in modern infrastructure and adopt Industry 4.0 technologies for smart manufacturing.

How IMARC Can Help

At IMARC, we specialize in providing end-to-end support for setting up manufacturing plants in India. Our services include:

- Market Research and Strategic Insights: Success in manufacturing goes beyond plant setup—it requires a deep understanding of market trends, customer preferences, and competitive dynamics. IMARC Group offers:

- Detailed market research to identify demand patterns and growth opportunities.

- Strategic insights to position your products effectively in the market.

- Assistance in identifying suppliers and distribution channels.

- Comprehensive Pre-Feasibility Studies: At IMARC Group, we understand that every manufacturing plant setup is unique. Our pre-feasibility studies provide a detailed analysis of critical factors, such as Market Viability, Cost Assessment, location analysis, etc.

- Assistance in Location Selection: Choosing the right location for your manufacturing plant is crucial for operational efficiency and cost-effectiveness.

- Cost Estimation and Financial Analysis: Our experts provide detailed cost breakdowns, including:

- Land acquisition and construction costs.

- Machinery and equipment expenses.

- Labor and utility costs.

- Maintenance and operational costs.

- Regulatory Compliance and Licensing: Navigating the complex regulatory landscape is one of the most challenging aspects of setting up a manufacturing plant.

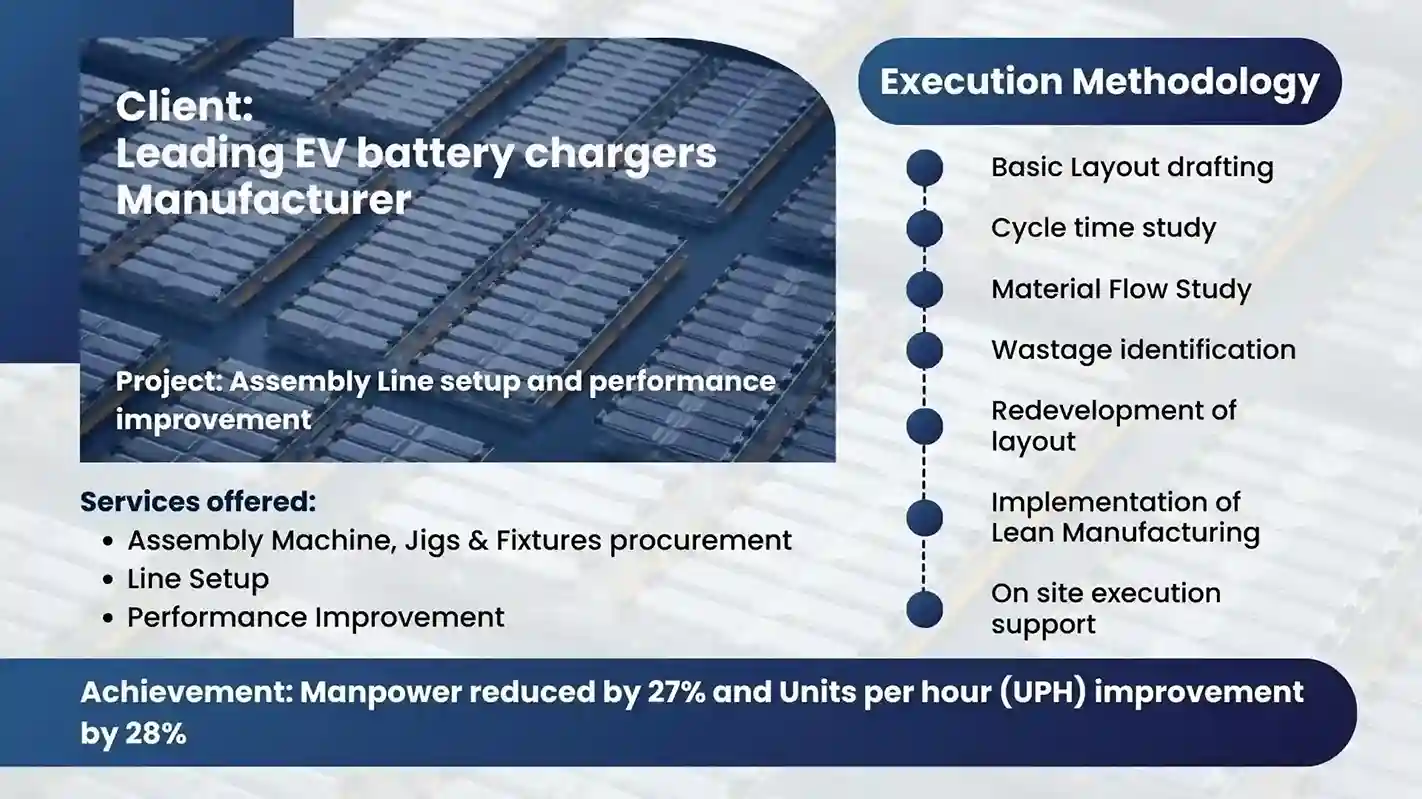

Case Studies of IMARC: Helping Companies Set Up Manufacturing Plants

IMARC has extensive experience assisting companies in their plant setup ventures. Some of our notable case studies include:

For more and detailed case studies, you can visit our Case Study Page

Challenges in Setting Up a Manufacturing Plant in India

While India offers immense opportunities, businesses may face certain challenges:

- Regulatory Complexity: Navigating through multiple laws and regulations can be daunting.

- Infrastructure Gaps: Despite improvements, some regions may lack adequate infrastructure.

- Land Acquisition: Securing land can be time-consuming and costly.

- Skilled Labor Shortage: While labour is abundant, finding highly skilled workers may require additional training.

Conclusion

The strategic choice to establish a manufacturing unit in India has major long-term advantages. Companies may overcome challenges and take advantage of the many opportunities in India with the help of competent advice, thorough understanding of legal frameworks, and strategic planning. At IMARC, we're dedicated to helping you every step of the way to ensure a smooth and effective implementation.

Are you ready to start? To find out how we, at IMARC, can assist you in setting up your manufacturing facility in India, get in touch today.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104