Financial Assessment of a Tennis Ball Manufacturing Plant: A Detailed Cost Model

What is Tennis Ball?

A tennis ball is a type of high-performance sporting ball used in both competitive and recreational tennis. On various court surfaces, its rubber core and felt covering provide the best bounce, speed, and durability.

Key Applications Across Industries:

Both pressurised and non-pressurized tennis balls are available to accommodate different playing situations and ability levels. Under international regulations, they are crucial for competitions and training, and business expansion is being driven by sustainability and material innovation.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global tennis ball market reached US$ 788.0 Million in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 5.1% from 2025 to 2033, reaching a projected size of US$ 1,235.3 Million by 2033. The growing popularity of tennis as a recreational and competitive activity is fuelling the global market for tennis balls.

Tennis's increasing appeal, especially among younger audiences, and growing health consciousness both support industry growth. Demand is also fuelled by the sport's inclusion in important international competitions, including as the Grand Slam events. Product appeal is increased by technological developments in ball durability, bounce uniformity, and pressure retention. Additionally, easier accessibility and broader distribution are made possible by the growth of e-commerce platforms. Another important factor driving demand is the growth of corporate sponsorships, tennis academies, and school programs. Sustainability trends are pushing producers to create biodegradable, eco-friendly tennis balls to appeal to consumers who care about the environment. Additionally, the growing popularity of tennis in Asia-Pacific's emerging markets—especially China and India—is propelling market expansion. All things considered, the tennis ball market is still growing as a result of increased participation, innovation, and distribution networks.

Case Study on Cost Model of Tennis Ball Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale tennis ball manufacturing plant in India.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 1,200,000 units of tennis balls.

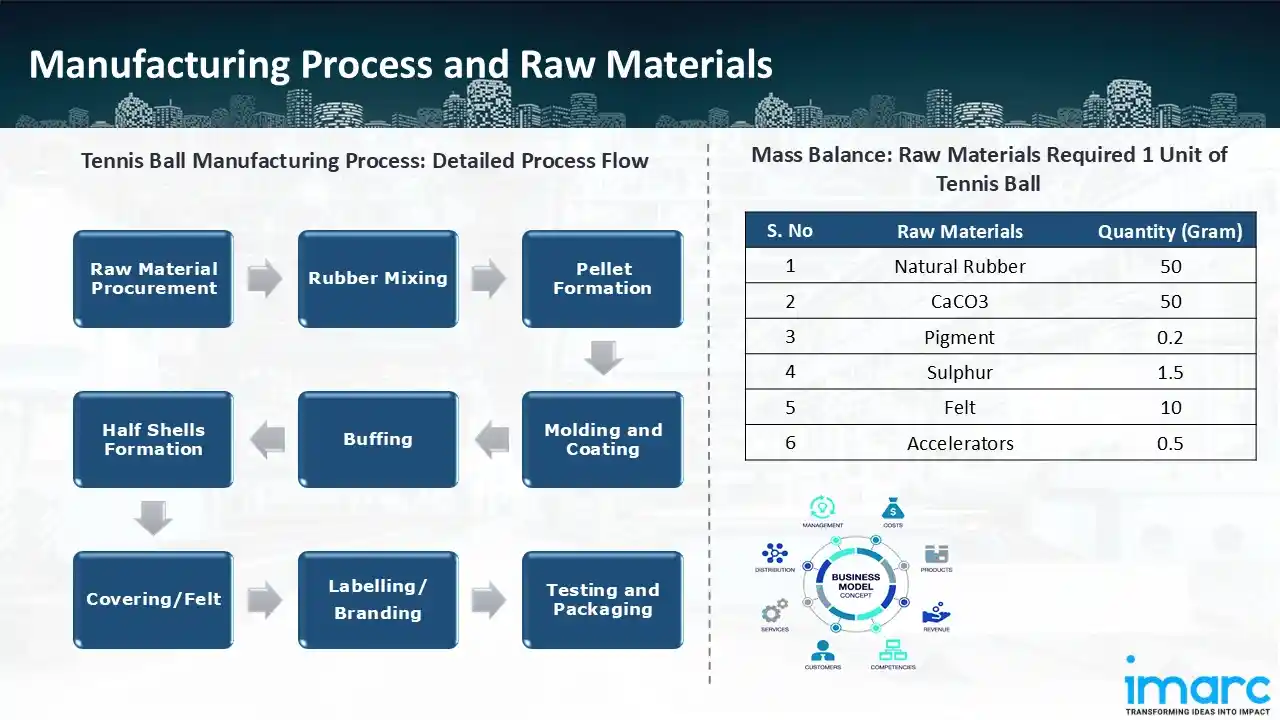

Manufacturing Process: Tennis balls go through several stages of production to guarantee performance, consistency, and durability. The first step in the process is Raw Material Procurement, when premium felt, and rubber are obtained. To obtain the required elasticity, natural and synthetic rubber compounds are combined at the Rubber Mixing stage. The combined rubber is then chopped and formed into tiny, homogeneous pellets, which will eventually make up the ball's core, a process known as pellet formation. These pellets go through moulding and coating, which produces a hollow rubber shell by vulcanising them under pressure and heat. After that, the shells undergo buffing, which evens out the surface for improved adherence later. The moulded rubber is split in half during the Half Shells Formation stage, and the two halves are then sealed together. The next step is Covering/Felt, when premium felt is meticulously glued on for maximum traction and longevity. Each ball is labelled or branded with the brand name and other required identification. Before the balls are packaged and sent for use in competitive and recreational tennis matches, the last testing and packaging step makes sure they fulfil quality criteria for bounce, weight, and durability.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the tennis ball manufacturing plant include natural rubber, CaCO3, pigment, sulphur, felt, and accelerators. To produce 1 unit of tennis ball, we require 50 grams of natural rubber, 50 grams of CaCO3, 0.2 gram of pigment, 1.5 gram of sulphur, 10 grams of felt, and 0.5 gram of accelerators.

List of Machinery:

The following equipment was required for the proposed plant:

- Rubber Kneader

- Roll Mixing Mill

- Rubber Extruder

- Hydraulic Compression Moulding Press (DayLight)

- Vulcanizing Machine

- BUCKET CONVEYOR or Lifter

- Rubber Cutter or Knife Cutter

- Motor & Starter

- Half Cup moulding Die

- Full Ball Curing Die

- Felt Dumbbell Cutting Press

- Bare Ball Abrading Drum with moto

- Cup Edges abrading Stone with motor

- Logo Printing Machine

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

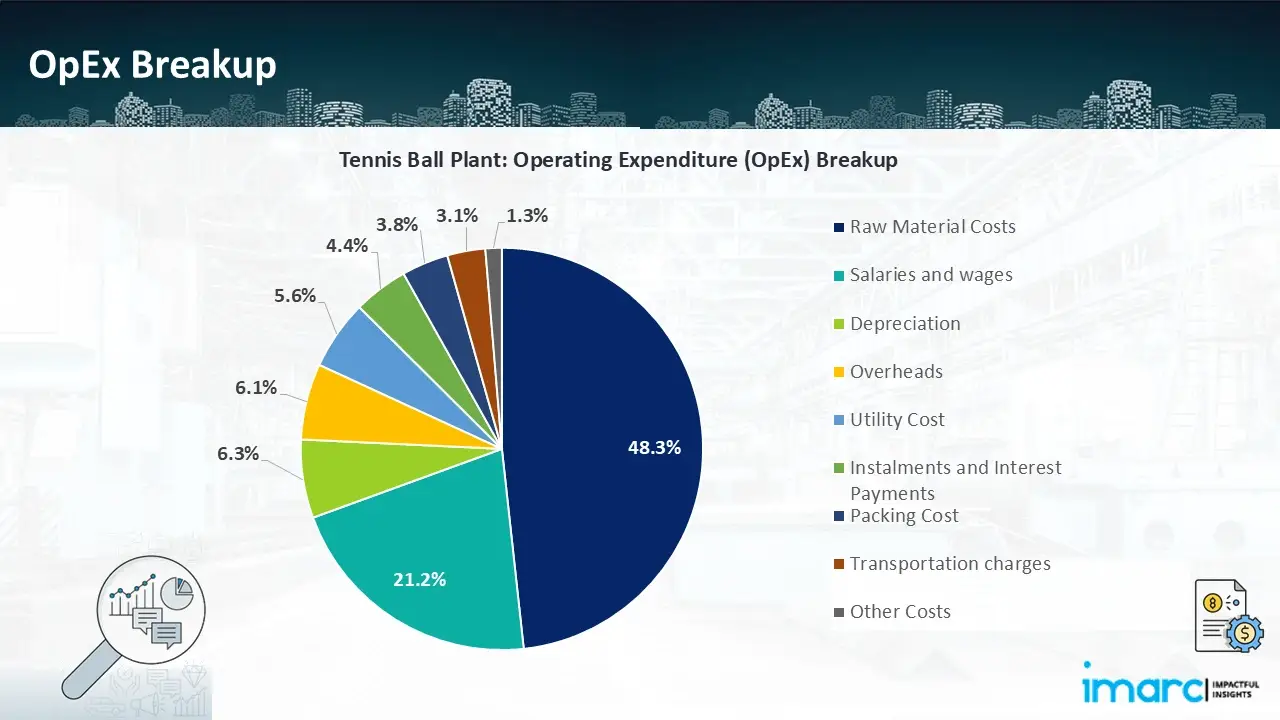

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

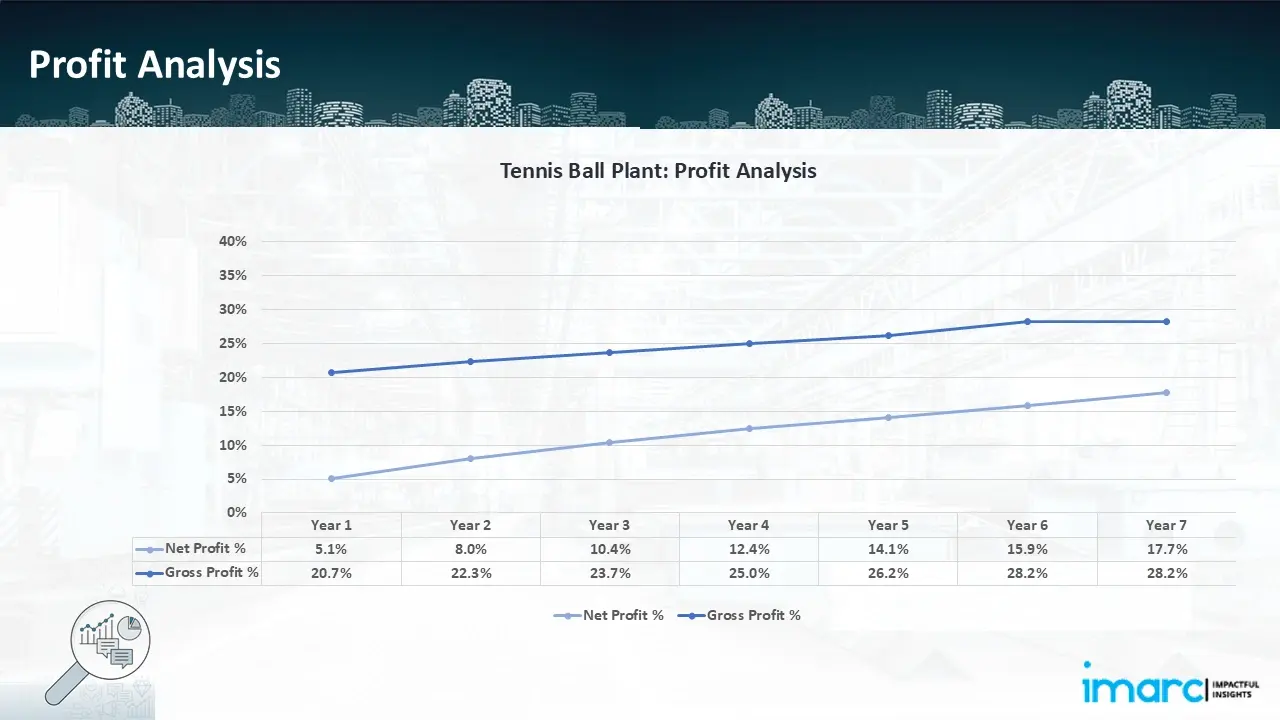

- Profitability Analysis Year on Year Basis: The proposed tennis ball plant, with an annual capacity of 1,200,000 units of tennis balls, achieved an impressive revenue of INR 22.5 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 20.7% to 28.2%, and net profit rise from 5.1% to 17.7%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our tennis ball manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 1,200,000 units of tennis ball annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In July 2024, Dunlop Sports Americas has announced a new relationship with the Intercollegiate Tennis Association (ITA). The ITA is appointing Dunlop as the Official Tennis Ball of the ITA and collegiate tennis as part of this partnership. Dunlop will also be recognised as the ITA's Exclusive Racquet and Accessory Brand, which will include bags, grips, and strings.

- In October 2021, Slinger Bag further expanded by acquiring PlaySight Interactive, a sports video and analytics platform. These strategic moves aim to enhance Slinger Bag's technological capabilities and market reach.

- In September 2021, Slinger Bag acquired Gameface.AI, an artificial intelligence platform for real-time biomechanics analysis.

- In June 2021, Slinger Bag, known for its portable tennis ball machine, expanded its portfolio through several acquisitions. The company acquired Foundation Tennis, a software provider for tennis facilities.

- In February 2021, HEAD Tennis, a world-renowned manufacturer of high-end, performance-oriented gear and clothing, will be the Laver Cup's Official Tennis Ball, Racquet, String, Stringer, and Racquet Bag.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104