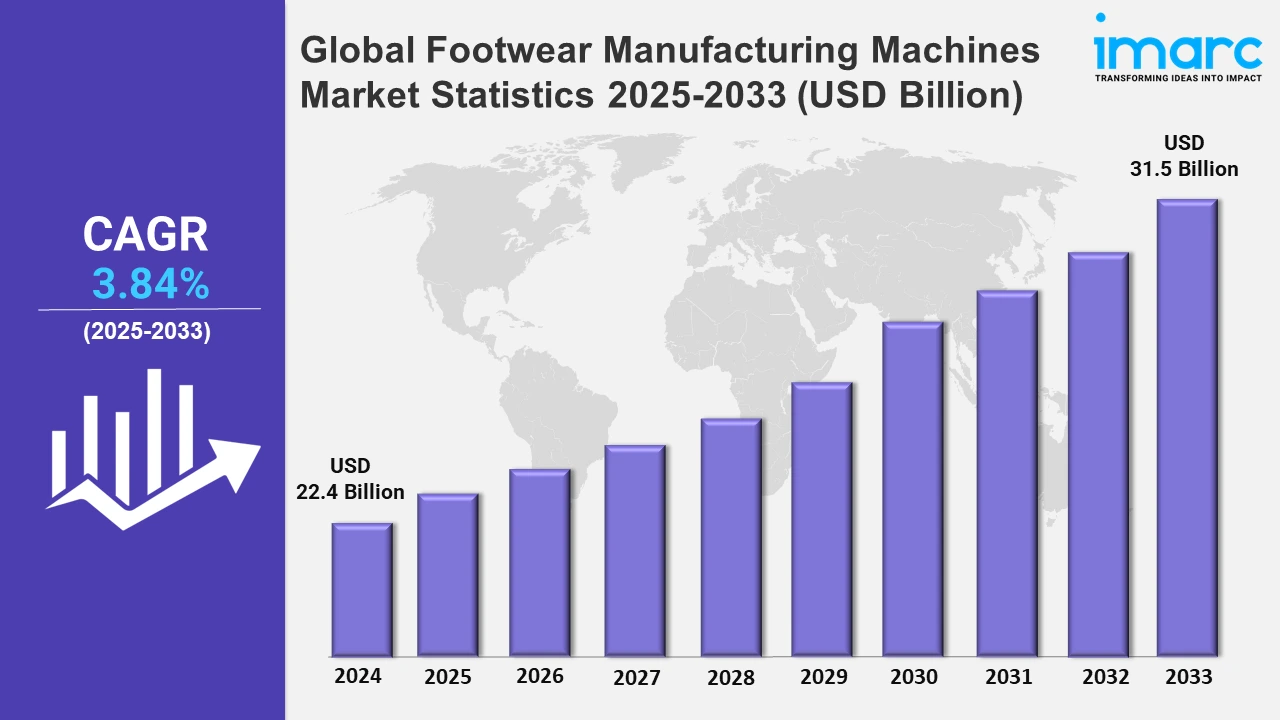

Global Footwear Manufacturing Machines Market Expected to Reach USD 31.5 Billion by 2033 - IMARC Group

Global Footwear Manufacturing Machines Market Statistics, Outlook and Regional Analysis 2025-2033

The global footwear manufacturing machines market size was valued at USD 22.4 Billion in 2024, and it is expected to reach USD 31.5 Billion by 2033, exhibiting a growth rate (CAGR) of 3.84% from 2025 to 2033.

To get more information on this market, Request Sample

The increasing adoption of automation and digital technologies is driving the footwear manufacturing machines market growth. On the contrary, manufacturers are focusing on streamlining production processes while maintaining sustainability and quality standards. Also, advanced automation for cutting, sewing, and assembly is emerging as a primary trend, which is enabling manufacturers to enhance efficiency and reduce manual labor. Integration of artificial intelligence (AI) and the Internet of Things (IoT) in production lines is transforming the footwear sector by ensuring precision and predictive maintenance. For instance, BSM India, in November 2024, unveiled cutting-edge machinery that incorporates digital prototyping tools and sustainable materials like mycelium leather. These developments highlight the industry's focus on reducing environmental impact and addressing the growing consumer demand for eco-friendly footwear options. In addition to automation, the industry is also exploring innovative technologies for faster and more cost-efficient production. For example, in September 2024, DESMA showcased advanced manufacturing machinery at its House Fair in Achim, Germany. These innovations included direct sole technology and sustainable production solutions, attracting over 800 visitors and 57 exhibitors.

Moreover, ACMI marked a significant milestone in October 2024 by opening an additive manufacturing centre in Indonesia. The facility focuses on advanced shoe mold production, which is equipped with Farsoon’s FS200M dual-laser and FS350M quad-laser metal additive manufacturing machines. This aims to improve lead times, enhance product quality, and offer cost-effective solutions, solidifying the industry's transition towards innovative and region-specific manufacturing hubs. The footwear manufacturing machines sector is adapting to new technological trends and aligning its production practices with evolving consumer preferences for sustainability and customization. Meanwhile, the integration of these advancements is positioning the industry to cater to the rising global demand for premium, eco-friendly footwear. The footwear manufacturing machines landscape is expected to evolve rapidly, as companies like BSM India, DESMA, and ACMI lead the charge with their innovative approaches.

Global Footwear Manufacturing Machines Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific dominates the footwear manufacturing machines market due to high production capacity, advanced automation adoption, cost-effective manufacturing, and strong demand from global footwear brands.

North America Footwear Manufacturing Machines Market Trends:

In North America, automation is a key trend, with advanced robotics optimizing production lines. In contrast, the U.S. leads in adopting technologies like 3D printing for customized footwear production. For instance, Stratasys offers 3D printing solutions used in shoe prototyping. Increased demand for sports and casual shoes is driving investments in high-precision manufacturing equipment, especially in states like California, where footwear brands seek faster production cycles.

Europe Footwear Manufacturing Machines Market Trends:

Sustainability-focused production in Europe is rising, with machines designed for eco-friendly materials. Germany, known for its engineering prowess, is a hub for innovative machinery that minimizes waste. Furthermore, companies like Desma produce equipment for recyclable polyurethane footwear. European brands emphasize energy-efficient machines to meet stringent environmental regulations, catering to consumer preferences for green manufacturing practices.

Asia Pacific Footwear Manufacturing Machines Market Trends:

Asia Pacific is the leading region in the market, driven by its high-speed machines improving efficiency. In addition, China leads the region with a surge in smart manufacturing technologies integrating AI for defect detection. For instance, companies are integrating robotic systems and AI-driven quality control mechanisms into their production lines. Taiwanese companies like Ever Precision provide cutting-edge machinery catering to large-scale operations. Rising demand for affordable footwear fuels the need for scalable and cost-effective manufacturing solutions in this region.

Latin America Footwear Manufacturing Machines Market Trends:

In Latin America, customization drives trends with machinery enabling tailored designs. Brazil, a leading footwear producer, adopts laser cutting and CNC machines for intricate designs. Local brands use flexible manufacturing systems to cater to niche markets, including handmade and artisan footwear. Also, this shift towards advanced machinery supports export-oriented growth in countries like Mexico and Brazil.

Middle East and Africa Footwear Manufacturing Machines Market Trends:

Investment in machinery for leather footwear production is increasing, driven by demand for luxury goods. South Africa is emerging as a hub, leveraging semi-automated machines for quality-focused production. Brands like Bata use specialized stitching equipment to enhance durability. The region is gradually embracing advanced manufacturing solutions, balancing traditional craftsmanship with modern techniques.

Top Companies Leading in the Footwear Manufacturing Machines Industry

Some of the leading footwear manufacturing machines market companies include ALC Tecnologie Adesive S.r.l., Atom S.p.A, Brustia Alfameccanica S.r.l., Comelz Spa, Dongguan Kingstone Shoe-making Machinery Co. Ltd., Gusbi SpA, Kou Yi Iron Works Co. Ltd., Orisol Taiwan Ltd., and True Ten Industrial Co. Ltd., among many others. In September 2024, Atom S.p.A unveiled the FlashCut Master 3185 at Simac Tanning Tech in Milan. This machine, designed for leather and footwear production, features dual cutting heads, IoT architecture, and a new nesting system. Atom also launched Shoemaster 21 for advanced 3D prototyping.

Global Footwear Manufacturing Machines Market Segmentation Coverage

- On the basis of the solutions, the market has been bifurcated into product (cutting machine, lasting machine, shoe stitching machine, closing machines (upper assembly), bottoming machines, finishing machines, and others) and services (maintenance and repair), wherein product (cutting machine, lasting machine, shoe stitching machine, closing machines (upper assembly), bottoming machines, finishing machines and others) represents the most preferred segment. Footwear manufacturing relies on specialized equipment designed for precision in shaping, assembling, and finishing shoes, ensuring efficiency, quality, and scalability across various production stages in the industry.

- Based on the machine type, the market is categorized into manual, automatic, and semi-automatic, amongst which semi-automatic dominates the market. Semi-automatic footwear manufacturing machines combine manual input with automated processes, enhancing production efficiency while retaining flexibility for customization and quality control in key stages like assembly, stitching, and finishing.

- On the basis of end user, the market has been divided into designer and commercial (athletic, casual, military, and others), wherein commercial (athletic, casual, military, and others) represents the most preferred segment. Footwear manufacturing machines cater to diverse market needs, enabling efficient production of specialized designs for performance, comfort, durability, and unique styles tailored to specific consumer and industry requirements.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 22.4 Billion |

| Market Forecast in 2033 | USD 31.5 Billion |

| Market Growth Rate 2025-2033 | 3.84% |

| Units | Billion USD |

| Solutions Covered |

|

| Machine Types Covered | Manual, Automatic, Semi-Automatic |

| End Users Covered |

|

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | ALC Tecnologie Adesive S.r.l., Atom S.p.A, Brustia Alfameccanica S.r.l., Comelz Spa, Dongguan Kingstone Shoe-making Machinery Co. Ltd., Gusbi SpA, Kou Yi Iron Works Co. Ltd., Orisol Taiwan Ltd., True Ten Industrial Co. Ltd., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)