Global Flow Chemistry Market Expected to Reach USD 4.5 Billion by 2033 - IMARC Group

Global Flow Chemistry Market Statistics, Outlook and Regional Analysis 2025-2033

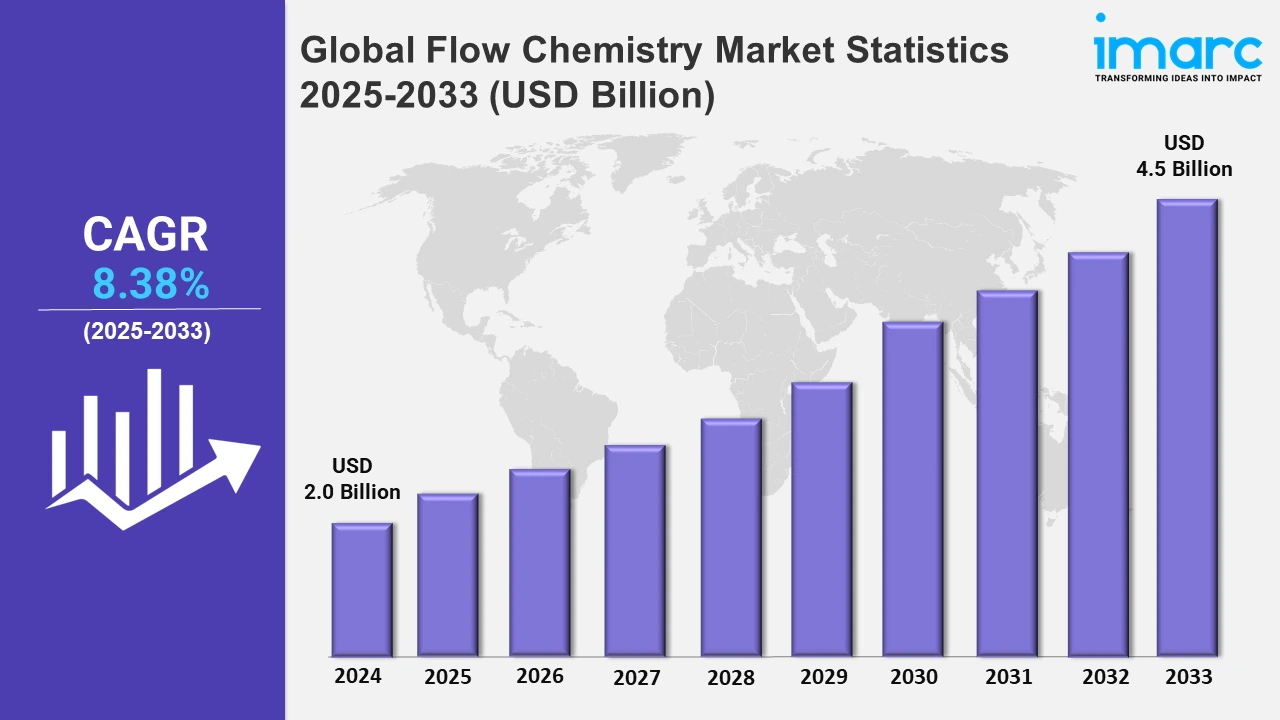

The global flow chemistry market size was valued at USD 2.0 Billion in 2024, and it is expected to reach USD 4.5 Billion by 2033, exhibiting a growth rate (CAGR) of 8.38% from 2025 to 2033.

To get more information on this market, Request Sample

One of the key drivers of the flow chemistry market is the increasing demand for sustainable and environmentally friendly chemical processing solutions. Flow chemistry systems significantly reduce waste and energy consumption compared to traditional batch processes. These systems enable precise reaction control, which minimizes byproducts and improves yield efficiency. This aligns with global regulatory mandates and industry goals for sustainable manufacturing practices, particularly in sectors like pharmaceuticals, petrochemicals, and fine chemicals. For instance, according to a research article published in World Journal of Pharmaceutical Research, in March 2024, green chemistry provides sustainable substitutes that can lower environmental impact while sustaining the efficacy and quality of pharmaceutical products. As industries focus on reducing their environmental footprint, the adoption of flow chemistry systems continues to rise, positioning them as a cornerstone of green chemical processing.

Another notable trend in the flow chemistry market is the integration of automation and digitalization technologies into chemical processes. Advanced flow reactors are increasingly equipped with real-time monitoring, predictive analytics, and automated controls, enabling enhanced process optimization and scalability. These innovations ensure consistent product quality and allow for rapid adjustments to meet dynamic market demands. Moreover, the ability to incorporate smart technologies is particularly advantageous for high-value applications in specialty chemicals and drug development. The trend toward Industry 4.0 adoption is further propelling the market, as businesses aim to leverage data-driven insights to enhance efficiency and maintain competitive advantages. For instance, as per industry reports, AI-driven predictive maintenance in chemical plants forecasts equipment failures, while machine learning models optimize processes by enhancing yields, reducing waste, and conserving energy. Moreover, predictive maintenance reduces downtime by 50% and extends machinery lifespan by 20%.

Global Flow Chemistry Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, North America accounted for the largest market share due to advanced industrial infrastructure, high adoption of innovative technologies, stringent environmental regulations, and significant investments in research and development initiatives.

North America Flow Chemistry Market Trends:

The North America flow chemistry market is witnessing robust growth driven by advancements in chemical processing technologies and a strong focus on sustainable manufacturing practices. The adoption of flow chemistry is increasing due to its ability to enhance efficiency, reduce waste, and improve safety in chemical synthesis. Furthermore, industries such as pharmaceuticals, petrochemicals, and specialty chemicals are leveraging this technology for cost-effective and scalable production. Additionally, the region's regulatory environment, emphasizing environmental sustainability and process optimization, further accelerates the adoption of flow chemistry systems across diverse industrial applications. For instance, in 2024, PyroGenesis Canada Inc. and HPQ Silicon Inc. announced progress on their Fumed Silica Reactor pilot plant, with equipment onsite and construction advancing for the 50 TPY facility. This involves a continuous process of converting quartz into fumed silica, aligning with the principles of flow chemistry.

Asia-Pacific Flow Chemistry Market Trends:

Asia-Pacific flow chemistry market is growing rapidly owing to increased industrialization and rising investments in chemical production and manufacturing, along with growing demand for efficient technologies of production. The sectors involved include pharmaceuticals, and petrochemicals, among others. They are utilizing the process for cost savings, scalability, and ecological benefits to facilitate the movement towards sustainable chemical processes within the region.

Europe Flow Chemistry Market Trends:

The Europe flow chemistry market continues to grow steadily, buoyed by strict environmental standards, state-of-the-art research facilities, and substantial adoption in pharmaceuticals as well as specialty chemicals. Industries in the region are implementing flow chemistry to improve efficiencies in production, minimize wastes, and comply with requirements for green manufacturing, keeping in step with the new European Union agenda.

Latin America Flow Chemistry Market Trends:

The Latin America flow chemistry market is gaining momentum, propelled by the growing chemical and pharmaceutical industries in the region. Increased investments in advanced manufacturing technologies and a growing focus on sustainable practices support the adoption of flow chemistry, which enables cost-effective production and improved efficiency across a wide range of industrial applications.

Middle East and Africa Flow Chemistry Market Trends:

The Middle East and Africa are experiencing growth in flow chemistry, supported by the extension of petrochemicals and pharmaceutical industries. Incremental investments in advanced processing technologies for chemicals, and optimizing production efficiency, are spurring the adoption of flow chemistry, as part of the region's drive to diversify industry and advance sustainability.

Top Companies Leading in the Flow Chemistry Industry

Some of the leading flow chemistry market companies include AM Technology, Chemtrix BV, Corning Incorporated, Ehrfeld Mikrotechnik GmbH, FutureChemistry Holding B.V., HEL Ltd., Lonza Group AG, Milestone Srl, Parr Instruments Company, Syrris Ltd (Asahi Glassplant Inc.), ThalesNano Inc, among many others. For instance, in January 2024, AGI Group acquired Chemtrix B.V., enhancing its portfolio with scalable flow reactors to advance flow chemistry and process intensification, supporting pilot and manufacturing solutions for industry and academia.

Global Flow Chemistry Market Segmentation Coverage

- On the basis of the reactor, the market has been categorized into continuous stirred tank reactor, plug flow reactor, microreactor, microwave system, and others, wherein continuous stirred tank reactor represents the leading segment due to its operational efficiency, scalability, and versatility in various chemical processes, making it the preferred choice across industries for consistent and high-quality output.

- Based on the application, the market is classified into pharmaceuticals, chemicals, academia and research, petrochemicals, and others, amongst which chemicals dominate the market due to the extensive use of reactors in producing specialty and bulk chemicals. Its versatility in facilitating diverse reactions and meeting high industrial demand underscores its leading position in the market.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 2.0 Billion |

| Market Forecast in 2033 | USD 4.5 Billion |

| Market Growth Rate 2025-2033 | 8.38% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Reactors Covered | Continuous Stirred Tank Reactor, Plug Flow Reactor, Microreactor, Microwave System, Others |

| Applications Covered | Pharmaceuticals, Chemicals, Academia and Research, Petrochemicals, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | AM Technology, Chemtrix BV, Corning Incorporated, Ehrfeld Mikrotechnik GmbH, FutureChemistry Holding B.V., HEL Ltd., Lonza Group AG, Milestone Srl, Parr Instruments Company, Syrris Ltd (Asahi Glassplant Inc.), ThalesNano Inc, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)