Global Ceramic Ball Bearings Market Expected to Reach USD 2,692.0 Million by 2033 - IMARC Group

Global Ceramic Ball Bearings Market Statistics, Outlook and Regional Analysis 2025-2033

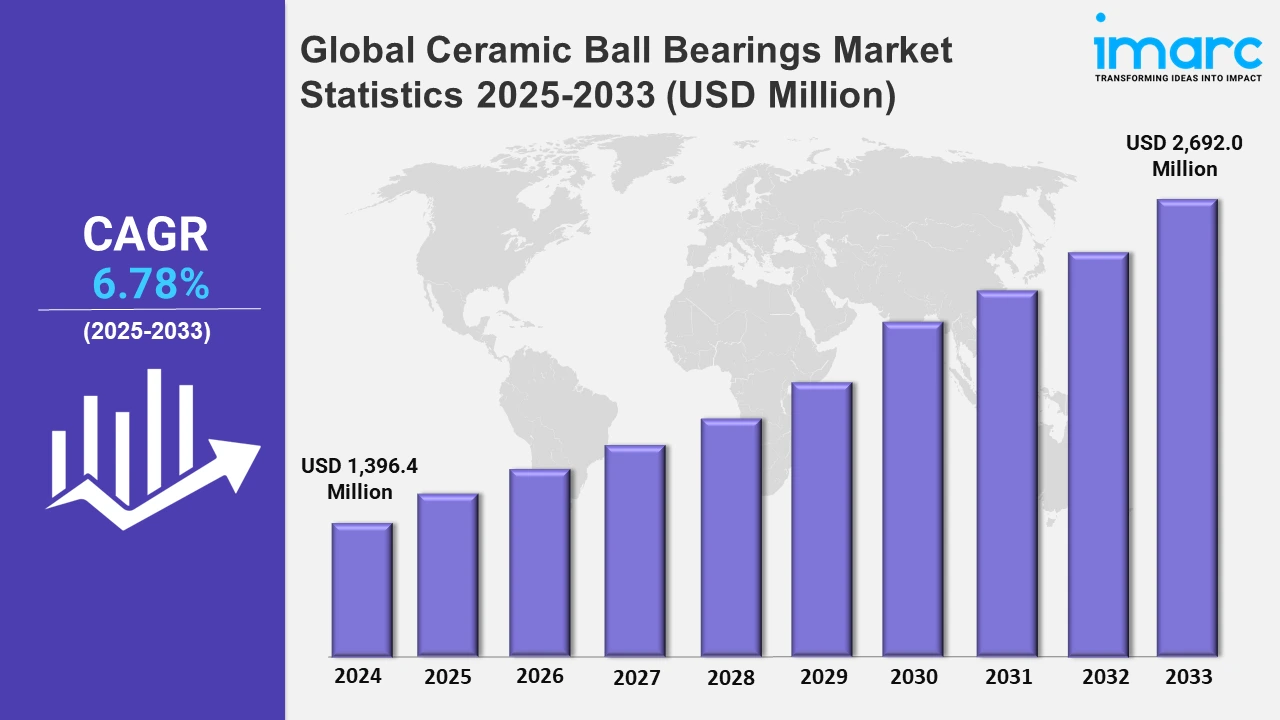

The global ceramic ball bearings market size was valued at USD 1,396.4 Million in 2024, and it is expected to reach USD 2,692.0 Million by 2033, exhibiting a growth rate (CAGR) of 6.78% from 2025 to 2033.

To get more information on this market, Request Sample

The ceramic ball bearings market is driven by the increasing demand for high-performance components across industries, such as electric motors, industrial machinery, and food processing. In addition, the superior properties of ceramic materials, including high durability, corrosion resistance, and thermal stability, are stimulating the market. Furthermore, advancements in hybrid ceramic bearings, which combine steel races with ceramic balls, are enhancing performance and expanding adoption in diverse applications. For instance, SKF announced advancements in ceramic ball bearing technology in October 2024, focusing on hybrid bearings designed for electric motors and industrial machinery. SKF aims to make these high-performance, electrically insulated bearings more accessible by optimizing in-house production and reducing costs. In line with this, in October 2024, ZEN Bearings introduced its Food and Beverage-Safe (FBS) line, featuring ceramic and hybrid bearings with FDA-compliant materials and PTFE seals. These bearings offer superior corrosion resistance and adhere to strict hygiene standards, making them ideal for food and beverage processing. Such developments are indicative of a broader trend toward application-specific innovations, aligning with the industry's demand for durable, efficient, and environmentally compliant solutions.

Moreover, these bearings are becoming important in addressing the challenges of energy efficiency and operational reliability, particularly in sectors focused on sustainability and low-maintenance solutions. At the same time, in September 2024, CeramicSpeed launched its Special Edition OSPW X pulley system showcasing ceramic bearings integrated with ADR technology. This system is designed for SRAM T-Type drivetrains, demonstrated exceptional performance in extreme conditions, such as the Cape Epic off-road cycling event. The durability and efficiency of CeramicSpeed’s product highlight the growing role of ceramic bearings in high-performance and niche markets like sports equipment. Overall, these innovations underscore the expanding scope of ceramic ball bearings as well as signify their importance in meeting the rigorous demands of modern engineering and performance standards.

Global Ceramic Ball Bearings Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include the United States, China, Europe, Japan, India, and South East Asia. According to the report, United States dominates the ceramic ball bearings market due to advancements in aerospace and defense sectors as well as robust manufacturing infrastructure.

United States Ceramic Ball Bearings Market Trends:

The United States is dominating the market due to extensive R&D activities, which enable companies to continuously innovate to meet the demands of advanced applications. For instance, in January 2024, Carter Americas highlighted its expertise by sponsoring Launch Canada 2023, showcasing ceramic ball bearings designed for LOX-kerosene rocket engines. These bearings exhibit exceptional durability under extreme conditions, reflecting their suitability for aerospace and cryogenic applications. Such advancements reinforce the U.S. position as a leader in the market, supported by the growing adoption of ceramic materials in industries like automotive, healthcare, and energy.

China Ceramic Ball Bearings Market Trends:

In China, the market is growing rapidly due to expanding industrial automation and electric vehicle (EV) sectors. For instance, Shenzhen-based BYD uses ceramic bearings for enhanced EV efficiency. Also, the increasing exports of high-performance machinery from Guangzhou further boost demand. Furthermore, the market across the country is driven by government investments in advanced manufacturing technologies, thereby promoting the use of durable and lightweight components like ceramic bearings.

Europe Ceramic Ball Bearings Market Trends:

In Europe, the market benefits from the region's robust aerospace and wind energy industries. Germany’s Siemens Gamesa employs ceramic bearings in wind turbines to reduce maintenance costs. In addition, demand is high in Paris for aerospace applications requiring lightweight, heat-resistant materials. Meanwhile, sustainability regulations and advanced production facilities further support market growth in ceramic bearings across European countries.

Japan Ceramic Ball Bearings Market Trends:

In Japan, the market thrives on technological innovation in robotics and high-speed rail systems. Moreover, companies in Tokyo, like NSK Ltd., incorporate ceramic bearings to improve robot efficiency and rail durability. Also, the country's focus on precision engineering and reliability ensures a steady demand for ceramic bearings, particularly in industries prioritizing high-speed and low-friction applications.

India Ceramic Ball Bearings Market Trends:

India's market for ceramic ball bearings is expanding due to the rising industrial automation and textile machinery needs in Surat. Ceramic bearings' durability suits humid and high-temperature conditions often seen in textile operations. Besides this, government initiatives like “Make in India” further drive demand for advanced components in manufacturing, including ceramic bearings, as industries modernize to enhance efficiency.

South East Asia Ceramic Ball Bearings Market Trends:

South East Asia, led by manufacturing hubs like Ho Chi Minh City, sees growing demand for ceramic ball bearings in precision machinery and electronics. On the contrary, Vietnam’s thriving semiconductor industry uses these bearings for their heat resistance and efficiency. Regional free trade agreements and investments in industrial sectors make ceramic bearings a preferred choice for high-performance applications in the region.

Top Companies Leading in the Ceramic Ball Bearings Industry

Some of the leading ceramic ball bearings market companies include AB SKF, NSK Ltd., NTN Corporation, Ortech Incorporated, CeramicSpeed, Shanghai Lily Bearing Manufacturing Co., Ltd., Boca Bearings, Inc., GMN Bearing USA Ltd., and JTEKT Corporation, among many others. In February 2024, NTN Corporation supplied ceramic ball bearings for the turbo pumps of the engine in the second H3 Launch Vehicle, developed by Tanegashima Space Center, highlighting their expertise in advanced aerospace applications.

Global Ceramic Ball Bearings Market Segmentation Coverage

- On the basis of the raw material, the market has been bifurcated into zirconium oxide, silicon nitride, and others, wherein zirconium oxide represents the most preferred segment. Zirconium oxide, known for its exceptional hardness, corrosion resistance, and high-temperature stability, enhances the overall performance and durability of these bearings.

- Based on the product type, the market is categorized into hybrid ceramic ball bearings and full ceramic ball bearings, amongst which hybrid ceramic ball bearings dominate the market. Hybrid bearings, integrating ceramic elements like silicon nitride or zirconium oxide with traditional steel components, offer a unique blend of strength and durability.

- On the basis of the application, the market has been divided into electric motor, automobile, under water equipment, laboratory equipment, aerospace, and others. Among these, electric motor exhibits a clear dominance in the market. Industries spanning automotive, manufacturing, and renewable energy prioritize these bearings for electric motors, enhancing overall efficiency and performance.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 1,396.4 Million |

| Market Forecast in 2033 | USD 2,692.0 Million |

| Market Growth Rate 2025-2033 | 6.78% |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Raw Materials Covered | Zirconium Oxide, Silicon Nitride, Others |

| Product Types Covered | Hybrid Ceramic Ball Bearings, Full Ceramic Ball Bearings |

| Applications Covered | Electric Motor, Automobile, Under Water Equipment, Laboratory Equipment, Aerospace, Others |

| Regions Covered | United States, China, Europe, Japan, India, South East Asia |

| Companies Covered | AB SKF, NSK Ltd., NTN Corporation, Ortech Incorporated, CeramicSpeed, Shanghai Lily Bearing Manufacturing Co., Ltd., Boca Bearings, Inc., GMN Bearing USA Ltd., JTEKT Corporation, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Ceramic Ball Bearings Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)