Global Azodicarbonamide Market Size Anticipated to Reach USD 2.02 Billion by 2033 - IMARC Group

Global Azodicarbonamide Market Statistics, Outlook and Regional Analysis 2025-2033

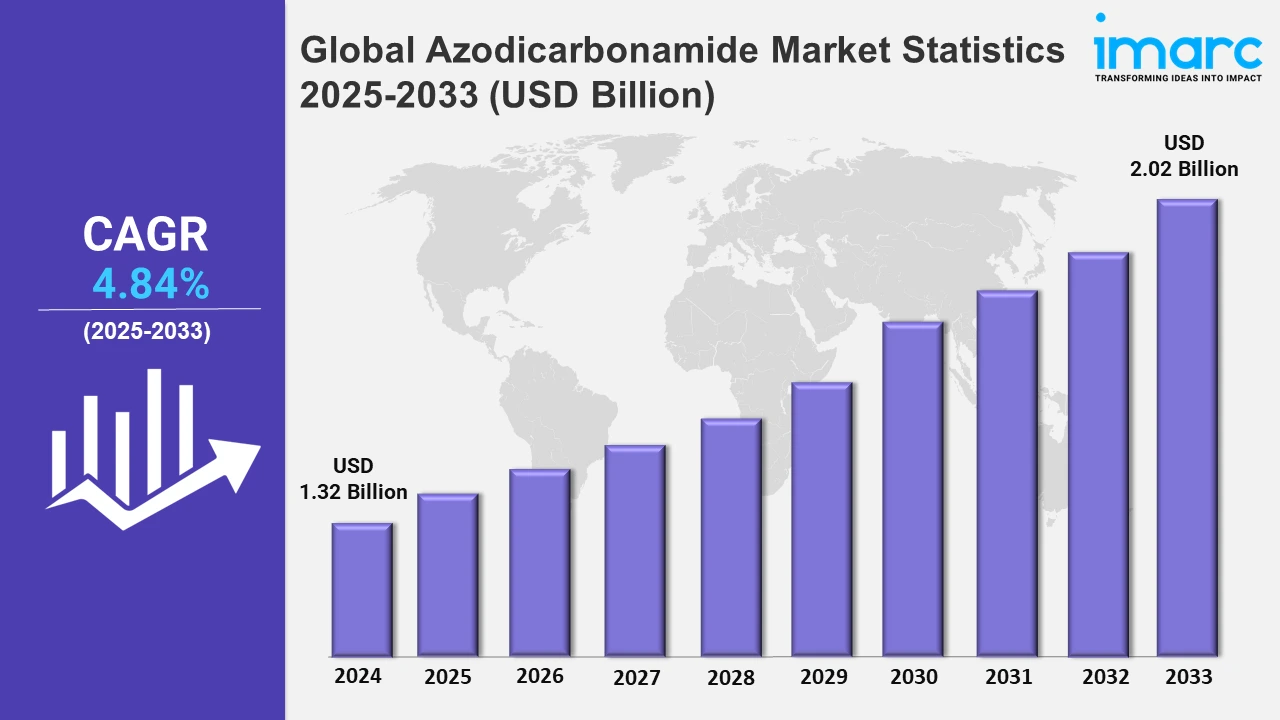

The global azodicarbonamide market size was valued at USD 1.32 Billion in 2024, and it is expected to reach USD 2.02 Billion by 2033, exhibiting a growth rate (CAGR) of 4.84% from 2025 to 2033.

To get more information on this market, Request Sample

One of the key factors driving the global azodicarbonamide market is its role as a chemical blowing agent in polymer and plastic production, which heavily relies on lightweight materials. Azodicarbonamide aids in reducing material weight, aligning with the needs of the automotive and packaging industries. These sectors prioritize fuel efficiency and optimal material utilization, making azodicarbonamide essential for meeting their performance and sustainability goals. For example, by 2024, ExxonMobil has committed to spend $200 million in Texas sites, expanding advanced recycling capacity toward 1 billion pounds annually by 2027, converting hard-to-recycle plastics into raw materials for circular economy solutions. This expansion further points out the demand for sustainable solutions in polymer and plastic manufacturing sectors where azodicarbonamide is a vital chemical blowing agent. Continued innovation in polymer blends will continue to increase the demand for azodicarbonamide, an important ingredient in these industries.

Manufacturers are increasingly prioritizing sustainability, focusing on eco-friendly production processes to minimize environmental impact. Products like azodicarbonamide, known for controlled decomposition and efficient foaming, play a pivotal role in improving material efficiency and reducing waste. This shift aligns with the industry's commitment to meeting stringent environmental regulations. The growing significance of azodicarbonamide in sustainable innovation is evident in its expanding applications, including its use in renewable energy sectors such as solar panel manufacturing. For example, in 2024, ChemCeed introduced its new sustainable, low-carbon footprint plasticizers for elastomers at the International Elastomer Conference 2024, highlighting innovative solutions for eco-friendly polymer processing. These innovations, by focusing on the reduction of carbon footprint and ensuring regulatory compliance, contribute to safer and more sustainable polymer processing practices.

Global Azodicarbonamide Market Statistics, By Region

The market research report has also provided a thorough analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, North America accounted for the largest market share on account of advanced manufacturing infrastructure, high demand for lightweight and durable materials, and strong presence of industries like automotive, construction, and packaging.

North America Azodicarbonamide Market Trends:

The North American azodicarbonamide market is driven by its huge utilization in plastics, rubber, and polymer industries, particularly in the sectors of lightweight automotive components and advanced packaging solutions. The increasing demand to use eco-friendly production processes and strict environmental regulations increase market growth. The region is also known for significant investments in R&D and innovative manufacturing in sustainable methods; thus, adoption continues in different industries. For example, according to recent data, Honeywell's Solstice Liquid Blowing Agent (LBA) is transforming the construction industry by enabling Mighty Buildings to produce 3D-printed homes with 99.9% lower global warming potential (GWP) compared to traditional methods. This innovative foam insulation supports low-emission, energy-efficient homes with near-zero waste, aligning with global sustainability goals. With the construction sector contributing 37% of global greenhouse gas emissions, Solstice LBA offers a crucial alternative, delivering superior thermal insulation and reducing heating and cooling energy needs. Since Azodicarbonamide is widely used as a blowing agent, this sustainable process will further increase its demand.

Asia-Pacific Azodicarbonamide Market Trends:

The Asia-Pacific azodicarbonamide market is growing due to its widespread use as a chemical blowing agent in plastics, rubber, and foam industries. Increasing demand from automotive, construction, and packaging sectors, coupled with expanding manufacturing capabilities in countries like China and India, drives the market's growth in this region.

Europe Azodicarbonamide Market Trends:

The Europe azodicarbonamide market is influenced by demand in automotive, construction, and packaging industries, focusing on lightweight and durable materials. Stricter environmental regulations are driving innovation in sustainable alternatives and efficient manufacturing processes. Leading companies are increasing their manufacturing capabilities to cater to rising demand in Germany, France, and the United Kingdom.

Latin America Azodicarbonamide Market Trends:

The Latin America azodicarbonamide market is growing due to rising demand in packaging, footwear, and automotive sectors. Countries like Brazil and Mexico lead in manufacturing foamed plastics and rubber products. Increasing investments in industrial development and the adoption of cost-effective production technologies further drive market growth in the region.

Middle East and Africa Azodicarbonamide Market Trends:

Due to increased demand in the construction, automotive, and packaging industries, the Middle East and Africa's azodicarbonamide market is growing. This growth is supported by rising urbanization, infrastructure development, and investments in manufacturing sectors, particularly in countries like South Africa, UAE, and Saudi Arabia, which are driving regional industrialization and market opportunities.

Top Companies Leading in the Azodicarbonamide Industry

Some of the major azodicarbonamide market companies include Abtonsmart Chemicals (Group)Co. Ltd., Guangzhou Jiangyan Chemical Co. Ltd, Haihang Industry Co. Ltd, JingJiang Hangsun Plastic Additives Co. Ltd, Ajanta Group of Industries, Khadgawats Group, Kumyang Co. Ltd., Lanxess AG, Nikunj Chemicals, Otsuka Chemical Co. Ltd, SPL Group, Weifang Yaxing Chemical Co. Ltd, among many others. In February 2024, LANXESS India expanded its Rhenodiv® production line at Jhagadia, increasing capacity for water-based, solvent-free, and VOC-free tire release agents. This facility enhances efficiency and sustainability in tire and elastomer production, meeting rising demand in the Indian Sub-continent and Asia while reinforcing LANXESS’s leadership in the rubber industry. The relevance of the azodicarbonamide market is evident here, as the compound plays a key role in producing lightweight rubber and polymer products, including foamed materials for tires and other rubber goods.

Global Azodicarbonamide Market Segmentation Coverage

- On the basis of the type, the market has been categorized into industrial and food quality. Azodicarbonamide is widely used as a chemical blowing agent in the production of foamed plastics and rubber goods for industrial applications. In the food-processing sector, food-grade azodicarbonamide primarily serves as a dough conditioner and flour bleaching agent.

- Based on the application, the market is classified into blowing agent, plastic additive, food additive, flour bleaching agent, and improving agent, amongst which blowing agent dominates the market due to their extensive use in producing lightweight foamed plastics and rubber materials for automotive, construction, and packaging industries, driven by demand for durable and energy-efficient solutions worldwide

- On the basis of the end user, the market has been divided into plastic and rubber, food and beverage, leather and textile, and others. Among these, plastic and rubber account for the majority of the market share due to the extensive use of azodicarbonamide as a blowing agent, enabling lightweight and durable materials for the automotive, construction, and packaging industries, driving significant demand.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 1.32 Billion |

| Market Forecast in 2033 | USD 2.02 Billion |

| Market Growth Rate 2025-2033 | 4.84% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical and Forecast Trends, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Types Covered | Industrial Quality, Food Quality |

| Applications Covered | Blowing Agent, Plastic Additive, Food Additive, Flour Bleaching Agent, Improving Agent |

| End Users Covered | Plastic and Rubber, Food and Beverage, Leather and Textile, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Abtonsmart Chemicals (Group)Co. Ltd., Ajanta Group of Industries, Guangzhou Jiangyan Chemical Co. Ltd, Haihang Industry Co. Ltd, JingJiang Hangsun Plastic Additives Co. Ltd, Khadgawats Group, Kumyang Co. Ltd., Lanxess AG, Nikunj Chemicals, Otsuka Chemical Co. Ltd, SPL Group, Weifang Yaxing Chemical Co. Ltd., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)