3D Concrete Printing Market Report by Product Type (Walls, Floors and Roofs, Panels and Lintels, Staircases, and Others), Concrete Type (Ready-mix, High-density, Precast, Shotcrete, and Others), Printing Type (Gantry System, Robotic Arm), End Use (Residential Building, Commercial Building, Infrastructure, and Others), and Region 2026-2034

3D Concrete Printing Market Size:

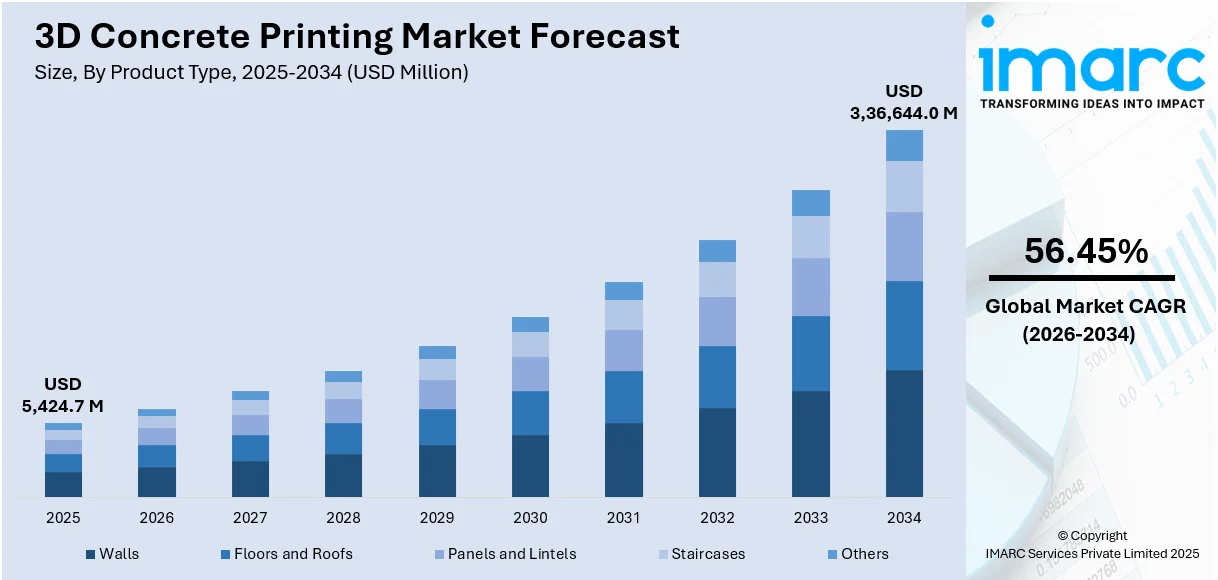

The global 3D concrete printing market size reached USD 5,424.7 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 3,36,644.0 Million by 2034, exhibiting a growth rate (CAGR) of 56.45% during 2026-2034. The market is mainly driven by the rising demand for sustainable and cost-effective construction solutions, the increasing need for faster construction processes and reduced labor costs, rapid production and intricate designs. This technology fosters sustainability through reduced waste and integrates advanced materials to enhance structural durability.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 5,424.7 Million |

| Market Forecast in 2034 | USD 3,36,644.0 Million |

| Market Growth Rate 2026-2034 | 56.45% |

3D Concrete Printing Market Analysis:

- Major Market Drivers: Key market drivers include the rising demand for cost effective and efficient construction method across the world which can reduce waste and environmental impact. Technological advancements in 3D concrete printing enable the printing of complex structures quickly and precisely which in turn reduces the overall project completion time and labor costs. In line with this, the rising focus on sustainable building practices and the potential for customization in architectural designs further propels the 3D concrete printing market growth. These factors are collectively making 3D concrete printing an attractive option for both commercial and residential construction projects which in turn leads to is rapid urbanization.

- Key Market Trends: Key market trends include advancements in automation and precision which promote faster construction time and reduced labor costs. The significant drive towards sustainability along with the technologies that enables significant reductions in waste and the use of eco-friendly materials. There is also a push towards customization, allowing for unique and complex architectural design that were previously difficult to achieve. Furthermore, the integration of advanced materials in 3D concrete printing enhances the overall durability and functionality of construction, broadening the technology’s application in modern building practices. These factors are creating a positive outlook for the 3D concrete printing market growth.

- Geographical Trends: Geographical trends in market shows significant growth in regions with growing construction sectors like Asia Pacific, mainly driven by urbanization and infrastructural development. North America and Europe are also adopting this technology gradually due to the rising awareness of sustainable building practices and the demand for custom-build homes. In In these developed markets, the push for innovation in construction methods is strong, fostering the adoption of 3D concrete printing. Meanwhile, Middle Eastern countries are exploring 3D concrete printing for its potential to quickly construct complex, design-oriented structures in challenging environments.

- Competitive Landscape: Some of the major market players in the 3D concrete printing industry include Apis Cor Inc., COBOD International, Contour3D, CyBe Construction, Heidelberg Materials, Hyperion, ICON Technology, Inc., Sika AG, Vertico, WASP S.r.l., XtreeE, Yingchuang Building Technique Co. Ltd. (WinSun), etc.

- Challenges and Opportunities: The market faces various challenges including technical limitations in printing large-scale structures and the high initial investment in specialized equipment. In line with this, there are regulatory and standardization hurdles which needs to be overcome as 3D concrete printing technology is still emerging. On the opportunity side, the market offers significant potential in reducing construction costs further enhancing building efficiencies and promoting sustainable practices. The ability to create complex designs and structures quickly also opens up new avenues in architectural innovation and customization, appealing to a broad spectrum of construction and design professionals.

To get more information on this market Request Sample

3D Concrete Printing Market Trends:

Integration of Automation and Robotics

In 3D concrete printing the integration of automation and robotics are increasingly pivotal mainly due to the precise construction processes and significant reduction in labor costs. These technologies allow for continuous, automated building of complex structures which enhances both the speed and quality of construction projects. For instance, in 2024, ABB Robotics and Simpliforge Creations are collaborating to advance 3D printing for India’s construction sector. Their joint efforts have already led to building South Asia largest robotic concrete 3D printer. This collaboration aims to enhance construction efficiency, sustainability and safety. By integrating robotics and 3D printing with traditional methods, the initiative is poised to transform construction across various sectors, including disaster affected areas.

Sustainability and Waste Reduction

The use of 3D concrete printing in construction significantly enhances sustainability and waste reduction. This technology utilizes precise material placement, ensuring that only the required amount of concrete is used, thereby minimizing excess. This precision not only reduces material waste but also lessens the environmental impact of construction projects by limiting unnecessary consumption of resources and decreasing debris. For instance, according to an article published by Cosmos in 2024, 3D printing allows for the direct deposition of materials at the point of use, eliminating virtually all waste. Studies show that 3D concrete printing can reduce material waste by up to 90%, representing a significant transformation in sustainable construction practices. Additionally, the technology enables the use of recycled and more sustainable materials, leading to potential cost savings. As a result, 3D concrete printing is emerging as an eco-friendlier alternative to traditional construction methods, aligning with global efforts to promote sustainable building practices.

Rising Demand for Faster Construction Process

The speed of construction is a significant advantage of 3D concrete printing, dramatically accelerating the building process. This technology enables the rapid creation of structures, significantly reducing the time required from start to completion compared to traditional construction methods. For instance, in 2023, Ajax Engineering introduced its own 3D Concrete printing machine, capable of constructing a 350-square-meter home in just 3 days. This technology offers rapid, cost-effective, and sustainable alternatives to conventional building methods, demonstrating scale at speed. The technology is not limited to homes but can be used for a wide range of structures. The company plans to invest 100 Crores in Karnataka for a new plant and production capacity enhancement, in line with its impressive YOY growth. This efficiency is especially beneficial for projects with tight deadlines or in situations where quick development is critical, such as after natural disasters. Faster construction not only speeds up project timelines but also potentially reduces labor costs and the overall financial input required.

3D Concrete Printing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2026-2034. Our report has categorized the market based on product type, concrete type, printing type, and end use.

Breakup by Product Type:

- Walls

- Floors and Roofs

- Panels and Lintels

- Staircases

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes walls, floors and roofs, panels and lintels, staircases, and others.

3D concrete printing for walls is revolutionizing building construction by allowing for the rapid creation of complex, customized wall structures. This method significantly reduces construction time and material waste compared to traditional building techniques. Additionally, 3D printed walls can incorporate unique architectural features and intricate designs that enhance aesthetic and functional aspects of buildings.

The use of 3D concrete printing to construct floors and roofs offers substantial advantages in terms of structural integrity and design flexibility. This technology enables the production of uniquely shaped and highly durable floors and roofs, which can be designed to optimize material usage and improve the building's overall energy efficiency. The ability to print complex geometries also opens up new possibilities for innovative architectural design.

3D printing of concrete panels and lintels allows for precise control over shape and size, leading to more accurate construction and less material wastage. This process is particularly beneficial for producing customized panels and lintels that fit specific design requirements or structural needs. Moreover, it reduces the lead time for production and installation, which is crucial for timely project completion.

Printing staircases with 3D concrete technology provides a fast, cost-effective method of creating durable and aesthetically pleasing stair configurations. This approach allows for seamless integration of complex designs and ornate patterns that would be difficult and expensive to achieve with conventional construction methods. The ability to print staircases in a single process reduces assembly time and construction complexity.

Breakup by Concrete Type:

- Ready-mix

- High-density

- Precast

- Shotcrete

- Others

A detailed breakup and analysis of the market based on the concrete type have also been provided in the report. This includes ready-mix, high-density, precast, shotcrete and others.

Ready-mix concrete is the most commonly used type in 3D concrete printing due to its consistent quality and ease of use. This concrete is pre-mixed at a facility according to precise specifications and then transported to the construction site, ensuring uniformity and reducing on-site labor needs. It is ideal for 3D printing as it provides reliable performance, optimal flowability, and quick setting times, essential for building stable and robust structures layer by layer.

High-density concrete is particularly valued in 3D printing for its superior strength and durability. This type of concrete is denser than standard concrete mixes, making it suitable for structures requiring enhanced resistance to mechanical stresses and environmental conditions. It is often used in constructing protective structures or buildings in seismic zones due to its ability to absorb and distribute energy more effectively.

In 3D concrete printing, precast concrete is used for creating elements that are cast and cured in a controlled factory environment before being transported and assembled on site. This approach is advantageous for repetitive structures as it ensures high quality and uniformity. Precast concrete components can be integrated with traditional construction methods to expedite the building process and enhance the structural integrity of installations.

Shotcrete is used in 3D concrete printing for projects that require the concrete to be applied at high velocity onto a surface, such as curved structures or complex forms. It is particularly useful for adding additional layers to existing concrete structures or in areas that are difficult to reach with traditional casting methods. Shotcrete in 3D printing allows for more artistic freedom in architectural designs and can be a fast method for constructing sculptural or non-linear shapes.

Breakup by Printing Type:

- Gantry System

- Robotic Arm

Gantry System represents the leading market segment

The report has provided a detailed breakup and analysis of the market based on the printing type. This includes gantry system and robotic arm. According to the report, gantry system represented the largest segment.

The gantry system segment dominates the 3D concrete printing market due to its high precision and ability to construct large scale structures efficiently. This system operates on a fixed structure or tracks which allows the printer head to move along multiple axes offering little control and accuracy in concrete deposition. It is particularly favored for constructing buildings or components in a controlled environment before assembly on site. Its scalability and versatility in handling diverse designs and materials makes it a highly sought after choice for various construction applications, from residential to commercial projects.

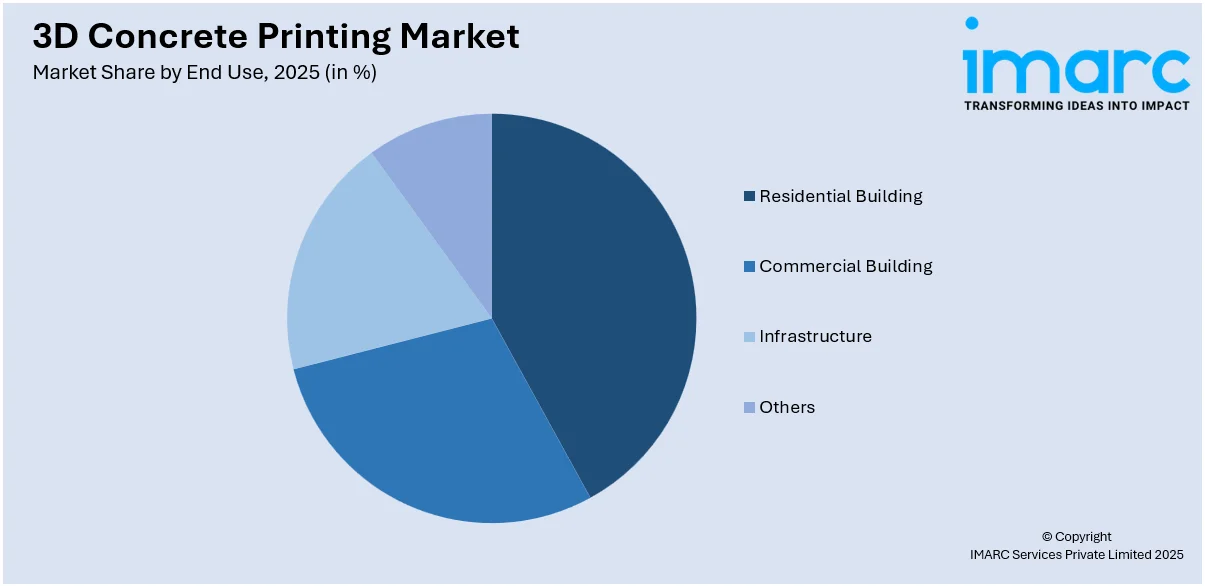

Breakup by End Use:

Access the comprehensive market breakdown Request Sample

- Residential Building

- Commercial Building

- Infrastructure

- Others

Residential Building exhibits a clear dominance in the market

A detailed breakup and analysis of the market based on the end use have also been provided in the report. This includes residential building, commercial building, infrastructure and others. According to the report, residential building accounted for the largest market share.

The residential building segment holds the largest market share in 3D concrete printing market mainly due to the rise in demand for affordable and rapidly constructed housing. 3D concrete printing technology offers a unique advantage in building homes efficiently with lower labor costs. Aligning with global trend towards sustainable and cost-effective construction solutions. This technology’s ability to customize designs and its reduced environmental impact also makes it highly appealing for residential construction, leading to its increasing adoption in creation of single and multifamily homes.

Breakup by Region:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Europe leads the market, accounting for the largest 3D concrete printing market share

The report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Europe represents the largest regional market for 3D concrete printing.

Europe holds a leading position in 3D concrete printing market reflecting to its proactive instance in adopting advanced construction technologies. This region's market dominance is supported by strict environmental regulations, which promote sustainable building practices, extensive R&D activities and significant investments in infrastructure development. According to a report published by European Commission in 2020, Antwerp Belgium hosts the world's first One Piece 3D printing building a two-story model house. The 90-meter square house was created using fixed 3D printer and is three times stronger than typical brick construction. The entire printing process took three weeks, but as technology advances, it could be completed in two days. Supported by over €755,000 in ERDF grants, the house showcases emerging 3D printing technologies and allows for significant cost savings. In line with this, Europe benefits from a robust industrial base and a strong push towards innovation and construction techniques, which in turn drives the widespread adoption of 3D concrete printing across various sectors, mainly in residential and commercial building projects.

Competitive Landscape:

The 3D Concrete Printing market features a competitive landscape marked by several key players driving innovation and market growth. Prominent companies include COBOD International A/S, CyBe Construction B.V., DUS Architects, Foster + Partners, known for their advanced 3D printing technologies and extensive project portfolios. These companies are pioneering new techniques to enhance the efficiency and capabilities of 3D concrete printing. For instance, in June 2024, Holcim acquired Land Recovery in the UK to advance its circular construction capabilities. The acquisition will help Holcim in reaching its goal of recycling 10 million tons of construction materials by 2024. Land Recovery specializes in recycling construction demolition materials and rail ballast for use in the UK rail network. This acquisition is in line with Holcim's commitment to sustainable building solutions and its mission to decarbonize buildings while improving living standards for all. Additionally, partnerships and collaborations with construction firms and real estate developers are common strategies to expand market presence. The competitive landscape is also characterized by continuous R&D investments to develop sustainable and cost-effective solutions, further propelling the market forward.

The report provides a comprehensive analysis of the competitive landscape in the global 3D concrete printing market with detailed profiles of all major companies, including:

- Apis Cor Inc.

- COBOD International

- Contour3D

- CyBe Construction

- Heidelberg Materials

- Hyperion

- ICON Technology, Inc.

- Sika AG

- Vertico

- WASP S.r.l.

- XtreeE

- Yingchuang Building Technique Co. Ltd. (WinSun)

3D Concrete Printing Market Recent Developments:

- In May 2024, Holcim Switzerland, in collaboration with PERI 3D Construction, completed the construction of Switzerland's first onsite 3D-printed building. The 150 m2 showroom, built for Kobelt AG, features striking curved walls reaching a height of 6.2 meters, showcasing a new concrete mix developed for sustainability and durability. The innovative design combines printed concrete with wood-steel elements, offering a fresh perspective on construction. This accomplishment sets a new benchmark for efficient and eco-friendly building practices in Switzerland.

- In May 2024, Heidelberg Materials acquired ACE Group, the largest supplier of pulverized fly ash in Malaysia, to enhance its position in the market and meet the growing demand for fly ash to reduce cement's CO₂ intensity. This move is part of the company's decarbonization strategy and will significantly reduce its CO₂ footprint in Southeast Asia. The acquisition involves three entities within ACE Group and aims to strengthen the circularity in Heidelberg Materials' value chain in the region.

3D Concrete Printing Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Walls, Floors and Roofs, Panels and Lintels, Staircases, Others |

| Concrete Types Covered | Ready-mix, High-density, Precast, Shotcrete, Others |

| Printing Types Covered | Gantry System, Robotic Arm |

| End Uses Covered | Residential Building, Commercial Building, Infrastructure, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Apis Cor Inc., COBOD International, Contour3D, CyBe Construction, Heidelberg Materials, Hyperion, ICON Technology, Inc., Sika AG, Vertico, WASP S.r.l., XtreeE, Yingchuang Building Technique Co. Ltd. (WinSun), etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the 3D concrete printing market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global 3D concrete printing market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the 3D concrete printing industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global 3D concrete printing market was valued at USD 5,424.7 Million in 2025.

We expect the global 3D concrete printing market to exhibit a CAGR of 56.45% during 2026-2034.

The rising demand for 3D concrete printing method over various conventional construction techniques, as it provides design flexibility, minimizes material wastage, enhances productivity, etc., is currently driving the global 3D concrete printing market.

The sudden outbreak of the COVID-19 pandemic had led to the implementation of stringent lockdown regulations across several nations resulting in temporary halt in numerous construction activities, thereby limiting the demand for 3D concrete printing.

Based on the printing type, the global 3D concrete printing market has been segmented into gantry system and robotic arm. Currently, gantry system represents the largest market share.

Based on the end use, the global 3D concrete printing market can be bifurcated into residential building, commercial building, infrastructure, and others. Among these, residential building accounts for the majority of the total market share.

On a regional level, the market has been classified into North America, Europe, Asia-Pacific, Middle East and Africa and Latin America, where Europe currently dominates the global market.

Some of the major players in the global 3D concrete printing market include Apis Cor Inc., COBOD International, Contour3D, CyBe Construction, Heidelberg Materials, Hyperion, ICON Technology, Inc., Sika AG, Vertico, WASP S.r.l., XtreeE and Yingchuang Building Technique Co. Ltd. (WinSun).

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)